Description

Learn what creep is, how temperature and stress control creep life, and which creep models CAE tools (ANSYS, COMSOL, Abaqus and others) use. Simple equations, practical CAE workflows, ASME / code context, and industrial project examples (boilers, pressure vessels, turbines, heat exchangers).

What is creep?

Creep is permanent deformation that accumulates over time when a material is exposed to stress — especially at high temperature. Even with a constant load, strain can slowly increase and eventually cause failure. That’s why parts used at elevated temperatures or for long service lives (turbine blades, boiler tubes, pressure-vessel parts, thermal anchors) must be evaluated for creep from the design stage.

The three stages of creep

Under a constant stress and temperature, creep typically shows three stages:

- Primary (transient): decreasing creep rate as hardening occurs.

- Secondary (steady-state): near-constant creep rate — often used for life estimates.

- Tertiary: accelerating creep rate leading to rupture.

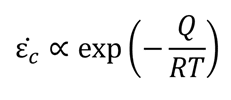

How temperature enters the law

Creep depends strongly on temperature. A common multiplier is Arrhenius-like:

where Q is activation energy, R the gas constant, and T absolute temperature. In CAE practice the pre-factor and other parameters are made temperature-dependent to reflect how creep accelerates with heat.

Core creep models used in CAE

Norton (power-law) steady-state

![]()

Good for secondary creep when you have steady-state data. A(T) often follows Arrhenius-type temperature dependence.

Time-hardening & strain-hardening transient capture

- Time-hardening:

- Strain-hardening: rewritten form to express rate as function of current strain

Useful when primary (transient) behavior is significant and you want a simple fit.

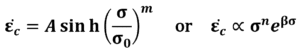

Sinh / exponential stress laws high-stress sensitivity

These forms capture rapid increases in creep at high stress.

Unified viscoplastic models (Perzyna, Chaboche, Anand)

Couple creep with plasticity and cyclic effects — important for creep-fatigue and complex load paths.

Theta projection (whole curve empirical fit)

![]()

A compact form that can fit primary → secondary → tertiary using a few coefficients that depend on stress and temperature. Useful in FEA where you want one expression that captures the full experimental curve.

How CAE packages use these models

- Thermo-mechanical coupling: run a thermal analysis (steady or transient) first → map temperature field to structural model.

- Material input: supply temperature-dependent creep coefficients, creep-rupture curves, and if needed, custom user routines.

- FEA practice: small time-steps in primary/tertiary phases, fine mesh near stress concentrators and welds, and convergence tolerance tuned for viscoplastic response.

- User customization: if built-in models aren’t enough, use user-material subroutines (e.g., Fortran CREEP style subroutines) or custom expressions in the solver.

Creep and lifetime, engineering checklist

- Collect data: creep curves, time-to-rupture at several temperatures/stresses.

- Choose model: Norton for steady-state, Theta or time-hardening for full-curve, unified viscoplastic for creep-fatigue.

- Simulate: couple thermal and structural analyses, use temperature-dependent properties.

- Evaluate life: compare creep strain/rate vs. allowable limits, use rupture curves or FFS approaches to estimate remaining life and inspection intervals.

- Report: show strain maps, redistribution, creep-fatigue results (if needed), and maintenance recommendations.

Theta projection method (FEA-focused)

The Theta projection fits the entire creep curve (primary → secondary → tertiary) with a compact form:

![]()

Coefficients v(i) are made functions of stress and temperature. In FEA, their derivatives are used directly to compute creep strain increments per timestep. Because Theta reproduces transient and long-term trends from short tests, it’s especially useful for predicting long-term behavior from accelerated experiments, and it handles complex geometry and non-uniform temperature fields well.

Industrial project examples (showcase): CAE + creep + ASME context

Below are concrete project examples where creep modeling is critical. For each, I list the typical CAE workflow and the ASME/code context engineers commonly consider.

1) Power boiler tubes & headers (ASME BPVC — Section I; Sections II materials)

Why creep matters: steam temperature and pressure over years cause tube sagging, ovalization and eventual failure.

CAE use: thermal transient (start-up/shutdown) → structural creep analysis with temperature-dependent Norton or Theta models → predict tube clearance loss, stress relaxation near supports, and time-to-rupture.

Code context: ASME Boiler & Pressure Vessel Code covers design of boilers and lists material allowable stresses at temperature; designers often combine CAE results with code allowable limits and material creep-rupture data to justify inspection intervals.

2) High-temperature pressure vessels & headers (ASME BPVC — Section VIII Div. 1/2)

Why creep matters: sustained high-pressure + high-temperature operation (petrochemical reactors, hydrogen service) causes creep deformation, weld creep, and possible leakage.

CAE use: map thermal fields into FEA model, study local stress concentrations (nozzles, saddles, welds), run long-term creep/transient analyses, evaluate stress redistribution and ratcheting.

Code context: Section VIII Div. 2 allows design-by-analysis methods; engineers use CAE to demonstrate stresses, creep deformation, and damage against code criteria and material allowable tables.

3) Turbine blades & discs (power generation / aero-derivative units)

Why creep matters: high temperatures and centrifugal stress cause time-dependent creep deformation and creep-fatigue, limiting life.

CAE use: coupled thermal + rotating structural analysis, creep model (often advanced sinh/exponential or custom laws), creep-rupture life and creep-fatigue interaction studies.

Practical outcome: CAE helps set inspection intervals, cooling design changes, and material/coating selection.

4) Heat exchangers & superheater coils

Why creep matters: localized hot spots and differential thermal expansion lead to sustained stresses and creep in tube supports and baffles.

CAE use: thermal mapping (fouling & fluid-side effects), creep simulation at hot-spots, evaluation of support design and expansion allowances.

5) High-temp piping systems and flare lines (process industry)

Why creep matters: long runs of piping at elevated temperature accumulate creep and can leak at flanges/welds.

CAE use: transient thermal+ structural analysis, creep ratcheting studies, combined creep-fatigue checks for cyclic loads. API/ASME fitness-for-service methods are often used to decide repairs.

6) Reactor / nuclear components (ASME Section III)

Why creep matters: long-term high-temp exposure, especially in some reactor internals, demands conservative life estimates and code compliance.

CAE use: high-fidelity creep and creep-fatigue simulation, combined with code-required material data and safety margins.

7) Welds & bolted connections in thermal plants

Why creep matters: local creep at weld heat-affected zones and reduction in preload due to relaxation.

CAE use: local mesh refinement, user creep model or Theta fit to capture HAZ behavior, check for leakage and loss of clamp force.

8) Fire protection / thermal anchor points & insulation supports

Why creep matters: elevated temperatures during a fire or repeated thermal cycles can creep-support hardware and compromise insulation or clamping systems.

CAE use: fire transient → map to structural creep model → evaluate deformation and failure modes to improve anchor design and material selection.

Typical CAE workflow for a pressure-vessel/boiler creep project

Collect material data: creep curves, rupture data at service temperatures.

- Run thermal simulation (steady or transient) for the operating or fire scenario.

- Map temperatures to structural model.

- Choose creep model (Norton, Theta, unified viscoplastic) and set temperature-dependent parameters.

- Run transient creep analysis with appropriate time-stepping and mesh refinement.

- Post-process: creep strain maps, redistributed stresses, predicted time-to-rupture, and inspection/repair recommendations.

- Compare results to ASME allowable stresses and fitness-for-service guidance (e.g., API/ASME FFS approaches) to finalize recommendations.

About the Author

Saman Hosseini – is a structural engineer who’s helped many researchers and engineers in academic and industrial projects to solve complex simulations. You can visit his Engineering Downloads profile here.