API 579 vs BS 7910

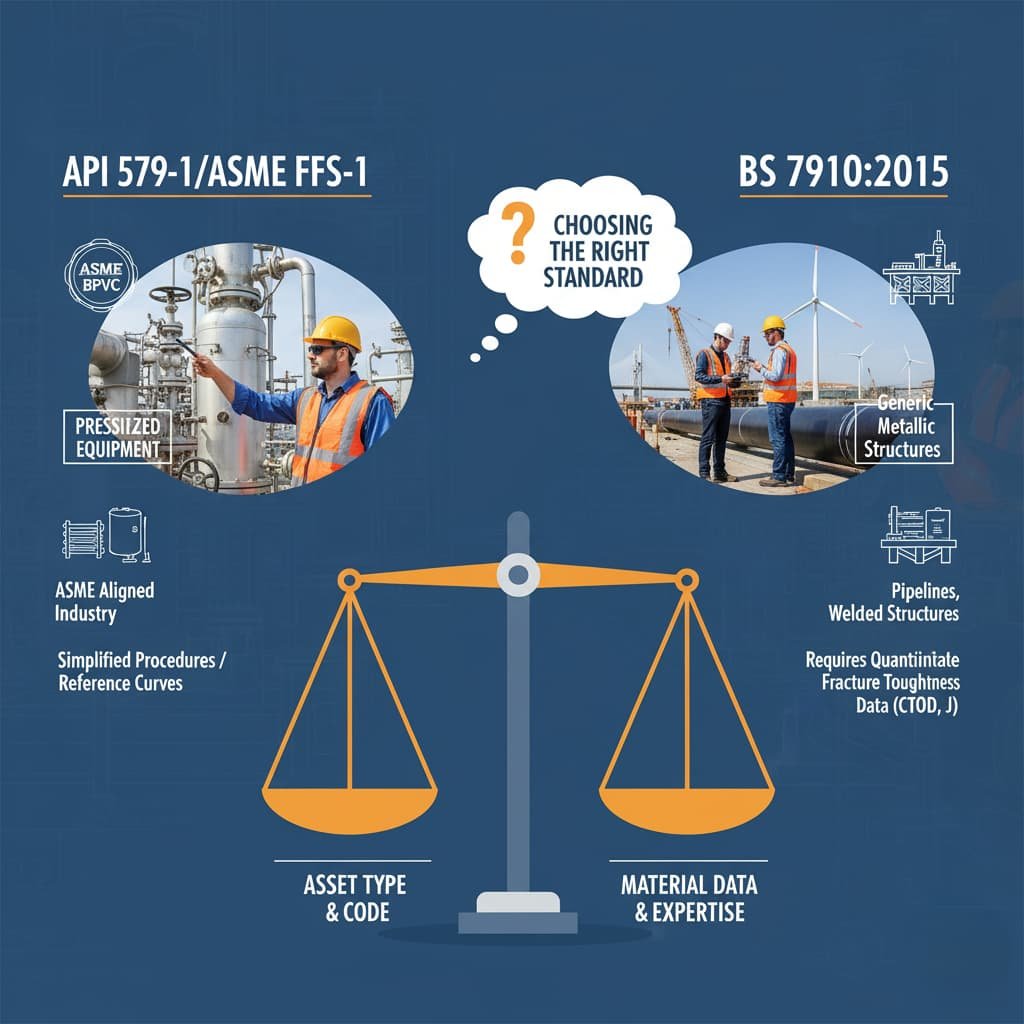

Fitness for Service (FFS) assessments help engineers decide whether a component with defects can continue operating safely. Different standards exist for performing these evaluations, and two of the most widely used are API 579‑1/ASME FFS‑1 and BS 7910. Both documents use fracture mechanics to determine whether flaws are acceptable, but their scopes and data requirements are not the same. Understanding these differences is essential for engineers and researchers who need to choose the right approach for a specific asset.

Understanding the Scope: General Guide vs. Pressurised Equipment

The British Standard BS 7910 is a generic guide that applies to all types of metallic structures and components. Because it was developed as a generalised procedure, it is not tied to any particular industry or design code; it allows engineers to decide appropriate safety margins and can be used for offshore structures, bridges, pressure vessels, pipelines and other metallic components.

By contrast, API 579‑1/ASME FFS‑1 is specifically designed for pressurised equipment used in the petrochemical and allied industries. It aligns with ASME design codes and covers a wide range of damage types—including general and local metal loss, pitting, blisters, hydrogen damage, misalignment and crack‑like flaws—typically encountered in refining and petrochemical plants. Because API 579 is tied to ASME codes, it provides results consistent with the original design safety margins.

Both standards adopt the fitness‑for‑purpose (FFP) concept, which deems a structure fit as long as failure conditions are not reached. Engineers perform an engineering assessment on known or hypothetical flaws to determine whether they remain within acceptable limits.

Using Failure Assessment Diagrams (FADs)

To judge whether a crack‑like flaw is acceptable, both BS 7910 and API 579 employ a failure assessment diagram (FAD). A FAD considers two failure modes:

- Fracture: either brittle fracture (where the material cracks suddenly) or ductile tearing (where the crack grows gradually).

- Plastic collapse: where the component loses its ability to support load because it yields or deforms excessively.

The FAD plots material toughness against applied load to create a safe/not‑safe boundary. Engineers calculate parameters such as stress intensity and reference stress, then plot the flaw on this diagram. If the assessment point falls inside the safe region, the flaw is acceptable; if it lies outside, repair or replacement is required. Check Out our new demo: Python-automated Abaqus FFS & FAD analysis

Fracture Toughness Requirements: Quantitative vs. Qualitative Data

A key difference between BS 7910 and API 579 lies in the fracture toughness data they require. The generic methods (like BS 7910) rely on quantitative fracture toughness parameters—such as the crack tip opening displacement (CTOD) or J‑integral—to determine the safe region on the FAD. These tests provide direct measurements of a material’s resistance to crack propagation, but they can be expensive, so comprehensive data may not always be available.

Pipeline‑specific or semi‑empirical methods often use Charpy V‑Notch (CVN) impact energy as a proxy for toughness. BS 7910 allows correlations to convert CVN values into CTOD or J‑integral, but these correlations depend on factors such as fracture mechanism and temperature. Choosing an inappropriate correlation can lead to inaccurate results, and generic methods tend to be more conservative than semi‑empirical methods.

API 579 includes an ASME reference curve for estimating fracture toughness of ferritic steels when direct data are unavailable. The curve fits stress intensity factors (K) versus temperature but imposes a cutoff at K<sub>IC</sub> = 220 MPa·√m for ferritic steels to reflect practical limits. This scheme allows a conservative lower‑bound estimate of toughness using a reference temperature derived from Charpy impact data.

Due to these differences, BS 7910 requires access to fracture parameter solutions and toughness data at all levels of assessment, whereas API 579 is designed so that plant inspectors can perform level 1 assessments with minimal data. Engineers should therefore consider what material data are available before choosing a standard.

Example Cases: Pressure Vessels vs. Pipelines

Consider a pressure vessel operating in a refinery. It was designed and fabricated according to the ASME Boiler and Pressure Vessel Code, and its fitness‑for‑service assessment must comply with those design margins. In this case, API 579 is a natural choice because it addresses common damage mechanisms in pressurised equipment and provides procedures consistent with ASME codes. If the vessel has a crack in a nozzle weld, engineers can use the FAD procedure from API 579 to evaluate whether the crack is acceptable at current operating pressures.

Now imagine a transmission pipeline constructed decades ago using steel with limited material data. The pipeline may experience external corrosion and occasional crack‑like defects from seam welds. Because BS 7910 is not tied to a specific design code, it can accommodate a wide range of pipe geometries and materials. Engineers could apply BS 7910 to determine the acceptable flaw size based on CTOD or CVN‑derived toughness. However, the ROSEN Group article notes that semi‑empirical pipeline‑specific methods, such as the NG‑18 equations or Ductile Flaw Growth Model, may be more accurate for ductile steels. In practice, pipeline operators often use BS 7910 or API 579 alongside industry‑specific methods to cross‑check results.

Decision Chart: Choosing Between API 579 and BS 7910

When selecting a fitness‑for‑service standard, consider the following criteria:

| Criterion | API 579‑1/ASME FFS‑1 | BS 7910 |

|---|---|---|

| Asset Type | Pressurised equipment (pressure vessels, storage tanks, piping in petrochemical plants) | Any metallic structure or component (pressure vessels, pipelines, welded structures, offshore platforms) |

| Design Code Alignment | Aligned with ASME design codes; results match original ASME safety margins | No specific design code; user selects safety margins |

| Data Requirements | Supports assessments with limited material data; includes reference curves for estimating fracture toughness | Requires quantitative fracture toughness data (CTOD or J) and fracture parameter solutions |

| Analysis Levels | Level 1 through Level 3; level 1 designed for plant inspectors with minimal data | Level 1 through Level 3; all levels require fracture mechanics expertise |

| Typical Uses | Assessing corrosion, cracks and other defects in pressure vessels, heat exchangers, storage tanks; rerating equipment designed to ASME codes | Assessing flaws in pipelines, welded structures, offshore platforms; cases where CTOD or J data are available or can be estimated |

| Fracture Toughness Approach | Uses ASME reference curve and correlation to Charpy impact energy | Uses correlations or direct CTOD/J‑integral values; correlations must be chosen carefully |

| Expertise Required | Less at level 1; more for advanced levels or fracture‑mechanics parts | Higher; requires fracture mechanics expertise at all levels |

Conclusion: Selecting the Right Standard

API 579 and BS 7910 are powerful tools for evaluating the fitness of components with flaws. API 579 is tailored for pressurised equipment designed to ASME codes and includes simplified procedures and reference curves for situations where data are limited. BS 7910 is a more general guide that can assess any metallic structure but requires access to detailed fracture toughness data and expertise in fracture mechanics. Both standards use failure assessment diagrams to balance fracture and plastic collapse, and both depend on accurate material properties and loading information.

Engineers should base their choice on the asset type, available data, regulatory requirements and internal competence. For pressure vessels and ASME‑designed equipment, API 579 may provide a straightforward path. For pipelines and structures where quantitative toughness data exist or can be estimated, BS 7910 offers a flexible framework. In cases where neither standard seems to fit perfectly, semi‑empirical pipeline methods or advanced FEA may be appropriate—consulting subject‑matter experts helps avoid misapplication.

A well‑informed selection ensures that defects are assessed accurately, maintaining safety and reliability while avoiding unnecessary repairs. Whether you’re an engineer assessing a refinery vessel or a researcher studying pipeline integrity, understanding the strengths and limitations of API 579 and BS 7910 is the first step toward confident, data‑driven decisions. Check Out our Understanding API 579 and FFS Assessment Levels Blog.