Intro

Acoustic metamaterials and acoustic meta surfaces are changing how we control sound waves. These specially designed structures go beyond the limits of traditional soundproofing. They offer new ways to control sound, such as reducing noise over a wide frequency range, blocking sound at very small scales, isolating vibrations, hiding objects from sound (acoustic cloaking), and adjusting absorption.

Unlike regular mass–spring–damper systems, which need heavy and bulky materials to block noise, acoustic metamaterials work better by using small-scale designs. These include locally resonant inclusions, spiral labyrinth channels, and periodic lattice structures. This allows for light, compact, and frequency-selective noise control, especially at low frequencies.

Planar meta surfaces, made of small, structured units like meta-lenses, can control how sound waves move. They can steer, focus, or absorb sound with very high precision.

Intelligent Acoustic Design for Advanced Engineering Applications

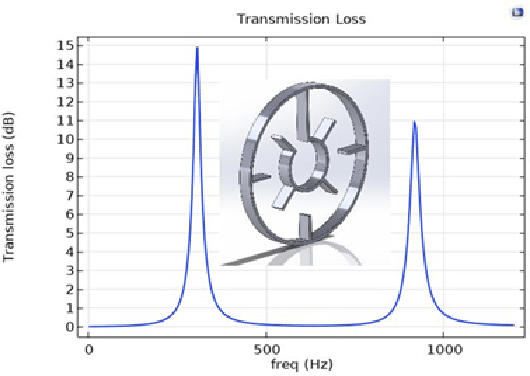

Modern acoustic metamaterials use different design methods to solve complex problems in how sound waves move. For example, locally resonant acoustic metamaterials (LRAMs) and membrane-type acoustic metamaterials (MAMs) are built to create acoustic bandgaps—frequency ranges where phononic waves (sound vibrations) cannot pass. This is very useful for passive noise and vibration control in fields like aerospace, automotive, construction, and consumer electronics, where designs must be compact, lightweight, and selective to certain frequencies.

More advanced designs, such as acoustic black hole (ABH) metamaterials, use changes in thickness to slow down and absorb vibration energy, working like non-reflective energy sinks. Other types, like Fano-resonant and Fabry–Perot metamaterials, use wave interference and cavity resonance to filter sound precisely. These are useful in sound filtering, acoustic imaging, and sensors that respond to their environment.

Engineers often design these structures using numerical simulations, like finite element modeling (FEM) in tools such as COMSOL Multiphysics or ANSYS. This helps to fine-tune the geometry, material properties, and vibration modes before making the final product.

As research continues in impedance matching, broadband tuning, and adaptive design, acoustic metamaterials will keep changing how we control and experience sound in both technical and immersive settings.

Key Applications

- Noise Reduction: Applied in aircraft cabins, vehicle interiors, and industrial enclosures using labyrinthine, coiled, and multi-resonant unit cells.

- Sound Insulation: Honeycomb core sandwich panels integrated with Helmholtz resonators for low-frequency attenuation in building acoustics.

- Acoustic Imaging: Use of negative refractive index metamaterials for subwavelength acoustic resolution in diagnostic and imaging systems.

- Adaptive Control: Development of magnetically tunable or 4D-printed structures for real-time acoustic property modulation.

- Industrial Applications: Compact, frequency-targeted noise control in compressors, turbomachinery, and defense-grade components.

Advantages

- Subwavelength Manipulation

- Lightweight Structural Integration

- Tailored Dispersion and Anisotropy

- Adaptive and Tunable Acoustic Behavior

Challenges

- Complex Microstructural Fabrication

- Narrow Operational Bandwidths (in some designs)

- Material and Processing Costs

- Long-Term Structural Durability

Conclusion

Acoustic metamaterials are changing how we understand and control sound. They allow precise control of wave behavior using effects like Helmholtz resonance, local resonance, acoustic black holes, and Fano interference. These techniques make it possible to design lightweight, tunable, and subwavelength-scale systems that traditional materials cannot achieve.

These materials have shown strong results in areas like smart buildings, vibration control, adaptive noise cancellation, and high-resolution acoustic devices. As research continues, more ways to use and integrate these materials are being developed. This makes acoustic metamaterials a promising technology that could transform acoustic engineering in many industries.