Product Overview:

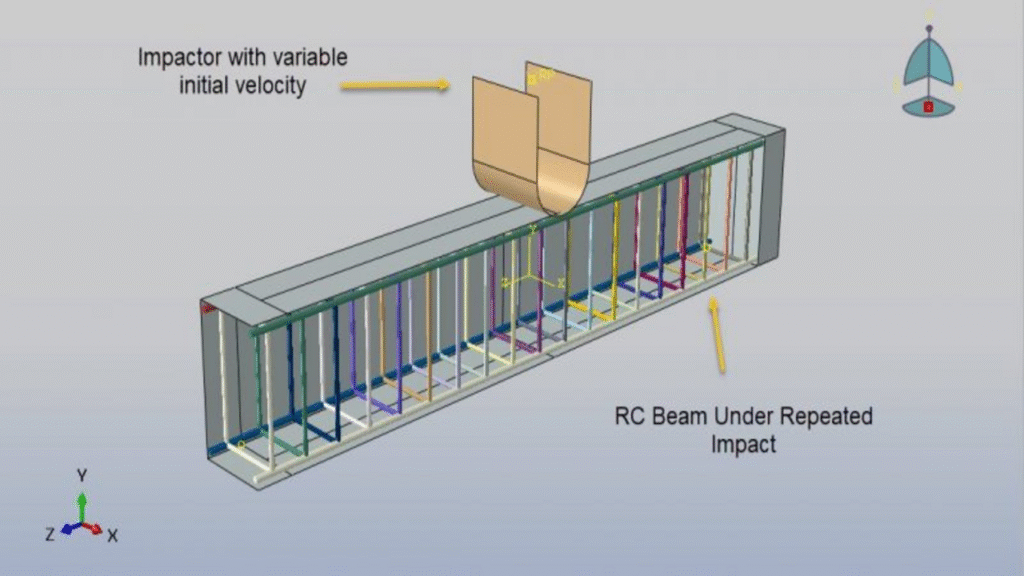

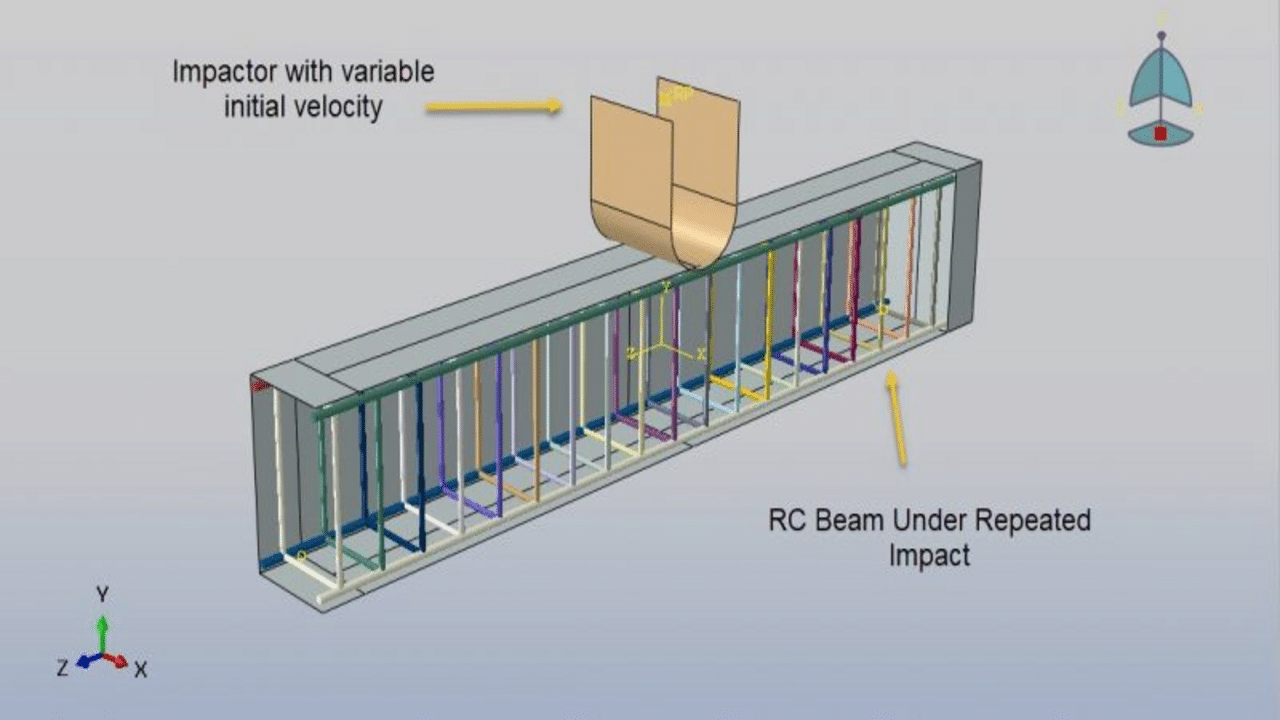

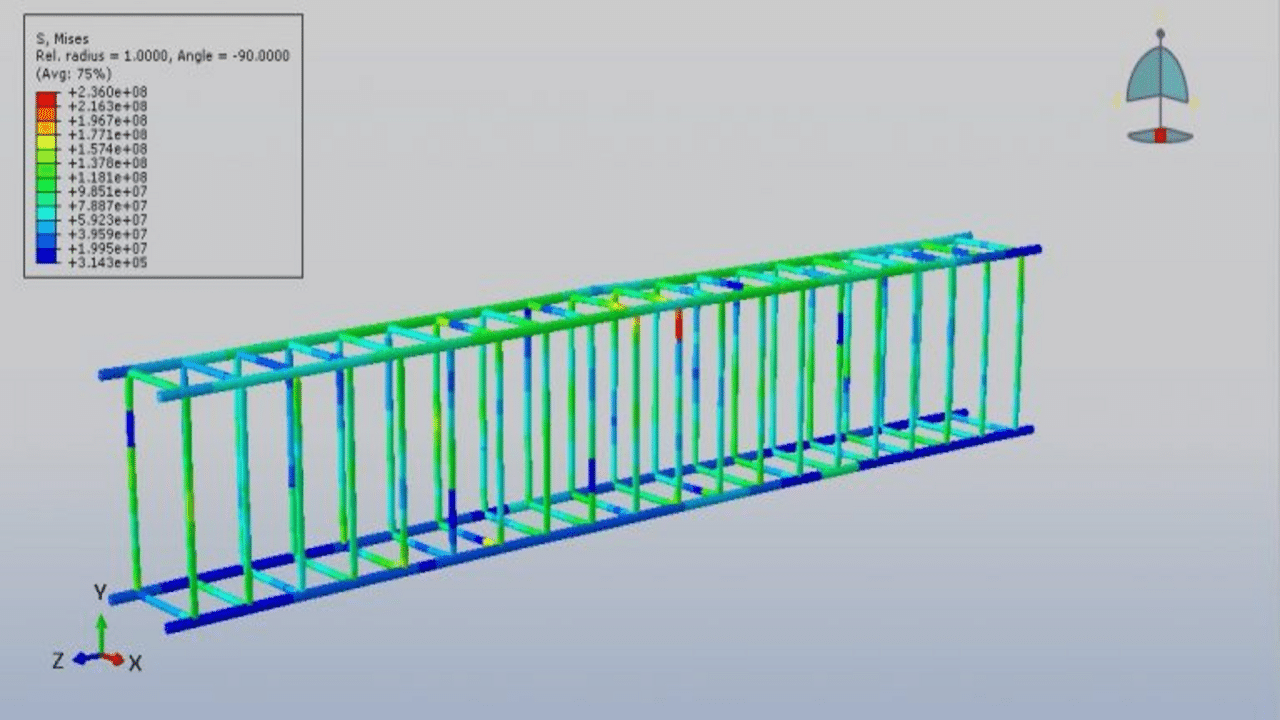

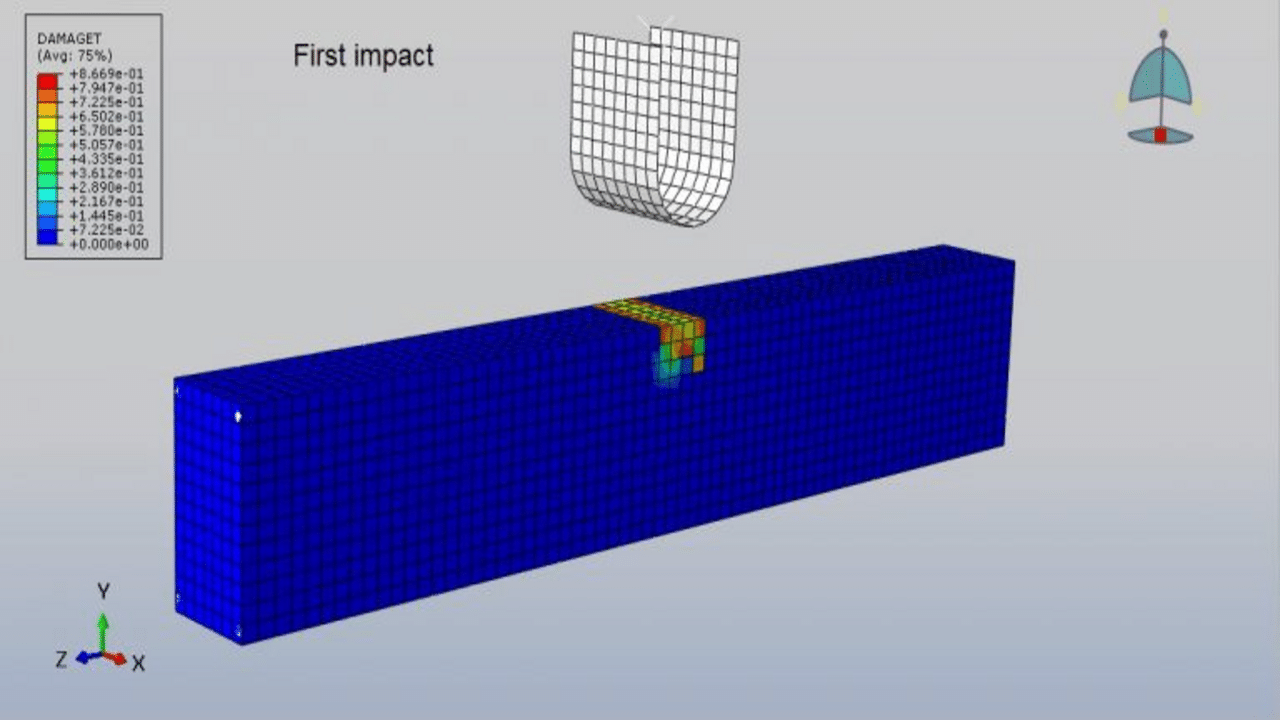

In this tutorial, the Simulation RC beam under the repeated impact of the rigid hammer in Abaqus has been investigated. The concrete beam is modeled as a three-dimensional solid part. The steel rebar and strips are modeled as three-dimensional wire parts. The rigid hammer is modeled as a three-dimensional rigid shell part.

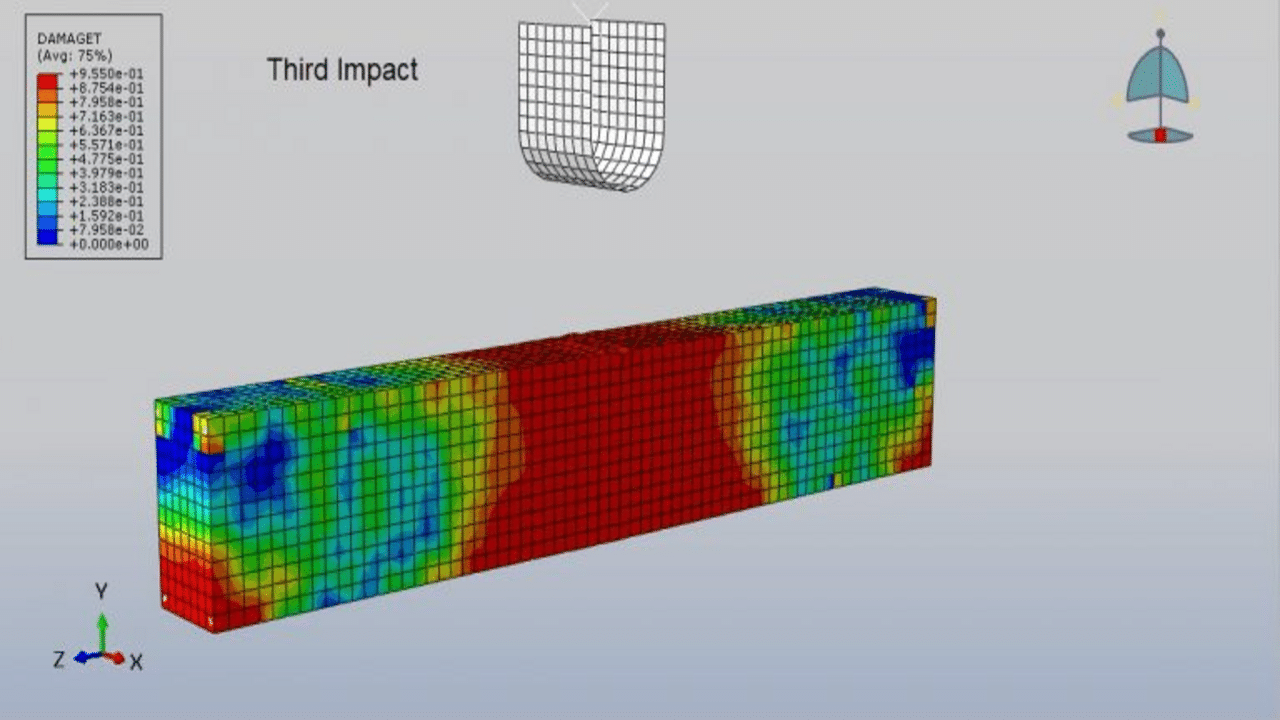

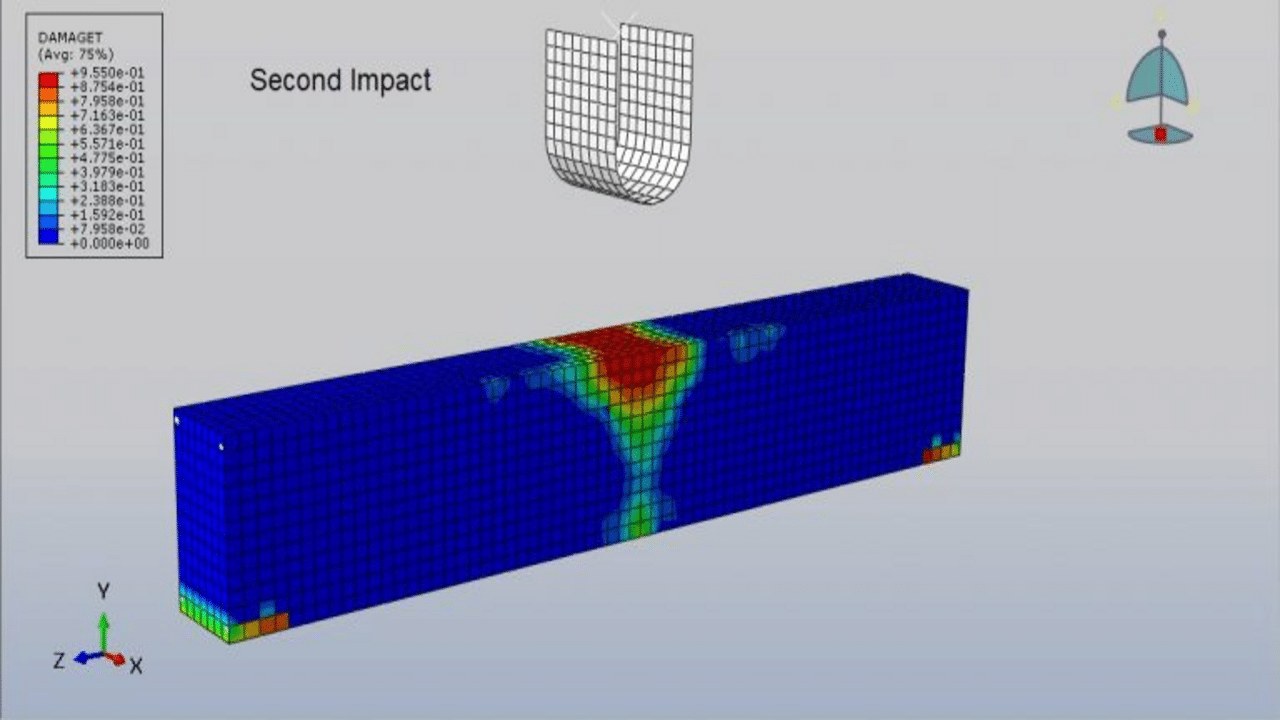

The concrete Damaged Plasticity is used to model concrete beams under low-energy impact. This model is a continuum, plasticity-based, damage model for concrete. It assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material. The tensile and compressive stress and damage are defined to obtain the damage in each impact. The elastic-plastic material model is selected to define steel reinforcements behavior

In this tutorial, three repeated impacts are considered and for all of them, a dynamic explicit step is used. The steel reinforcements are embedded inside the concrete host. The surface-to-surface contact with contact property as friction is selected to define contact between the hammer and RC beam. The fixed boundary condition is assigned to the beam and the initial velocity to the hammer. The mesh should be fine to achieve the correct resutls

After the first impact, all results such as stress, strain, tensile and compressive damage, reaction force, and … are available. To model the second impact, the results from the first impact are applied to all parts and then the second impact is done. To do the third impact, the results from the second impact are applied to all parts and the third impact is done. During repeated impact, the stress, strain, and damage are increased.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?