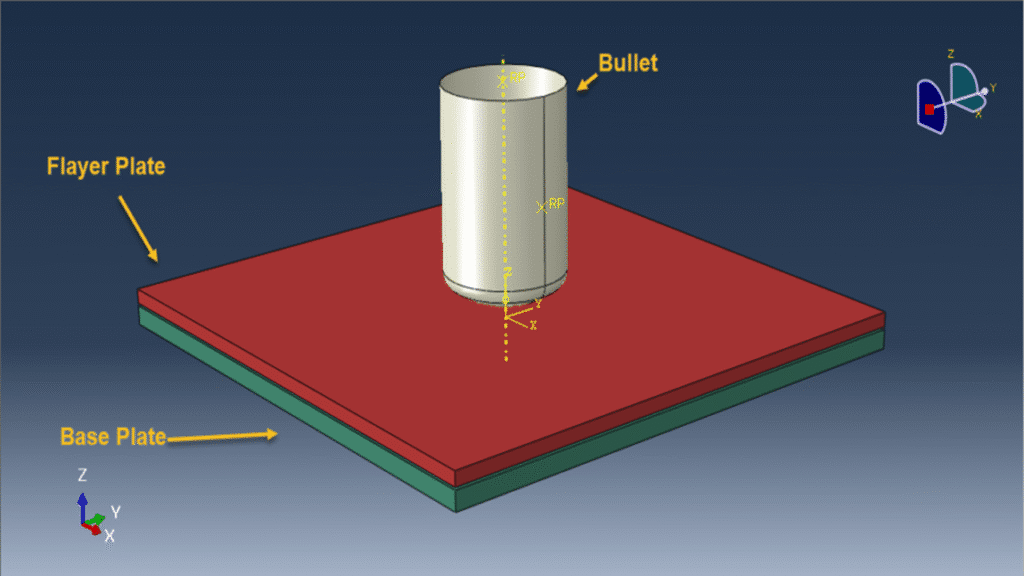

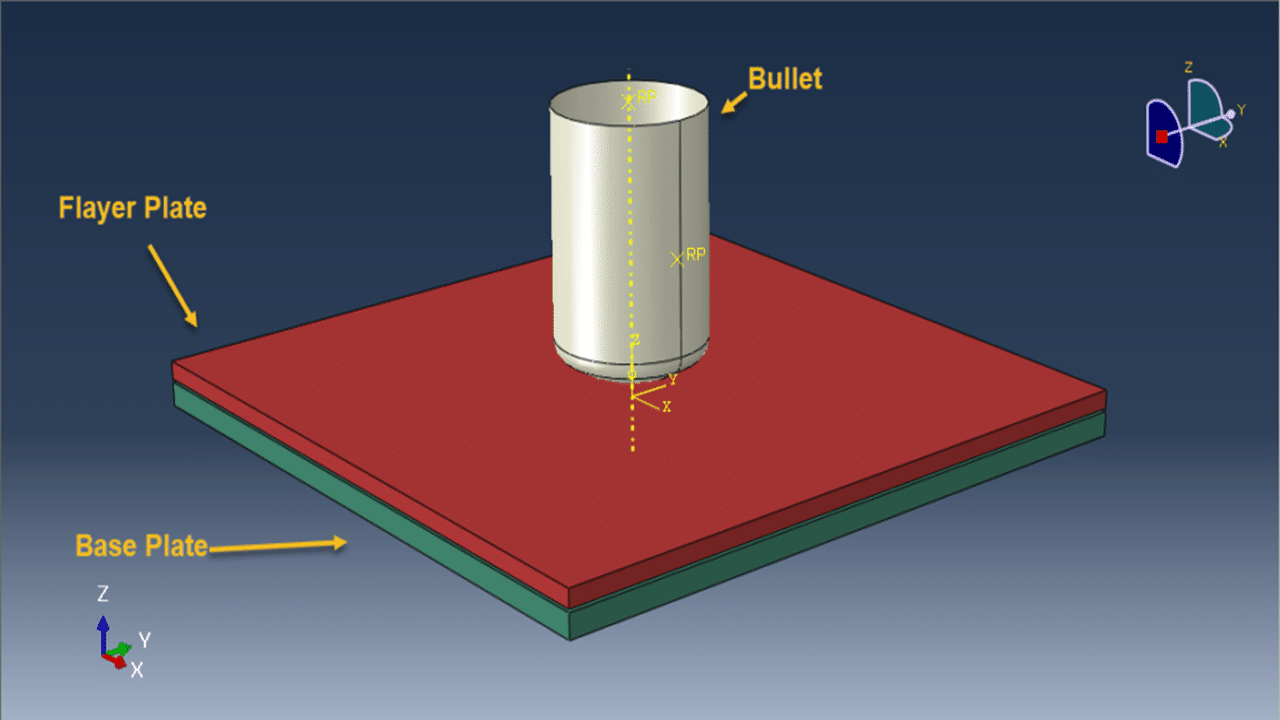

In this tutorial, the simulation of impact spot welding of two steel plates in Abaqus is performed. The steel flyer and base plates are modeled as three-dimensional solid parts, while the rigid impactor is modeled as a three-dimensional shell part. Welding processes are crucial for joining metal components. Traditional welding methods can alter the microstructure and mechanical properties of base materials due to thermal cycles, leading to issues like loss of ductility, cracking, formation of harmful phases, and reduced corrosion resistance. These challenges are amplified in heterogeneous welds due to differences in physical properties such as melting points.

Solid-state welding processes, which avoid extensive melting, offer a reliable alternative for joining dissimilar materials. Recent advances include magnetic pulse welding, laser impact welding, ultrasonic welding, friction stir welding, and projectile impact spot welding. High-speed impact welding is notable for its low welding temperatures and high welding velocities. The impact spot welding (ISW) process uses a high-velocity projectile to create atomic bonding between plates, involving complex mechanics, heat transfer, and material behavior.

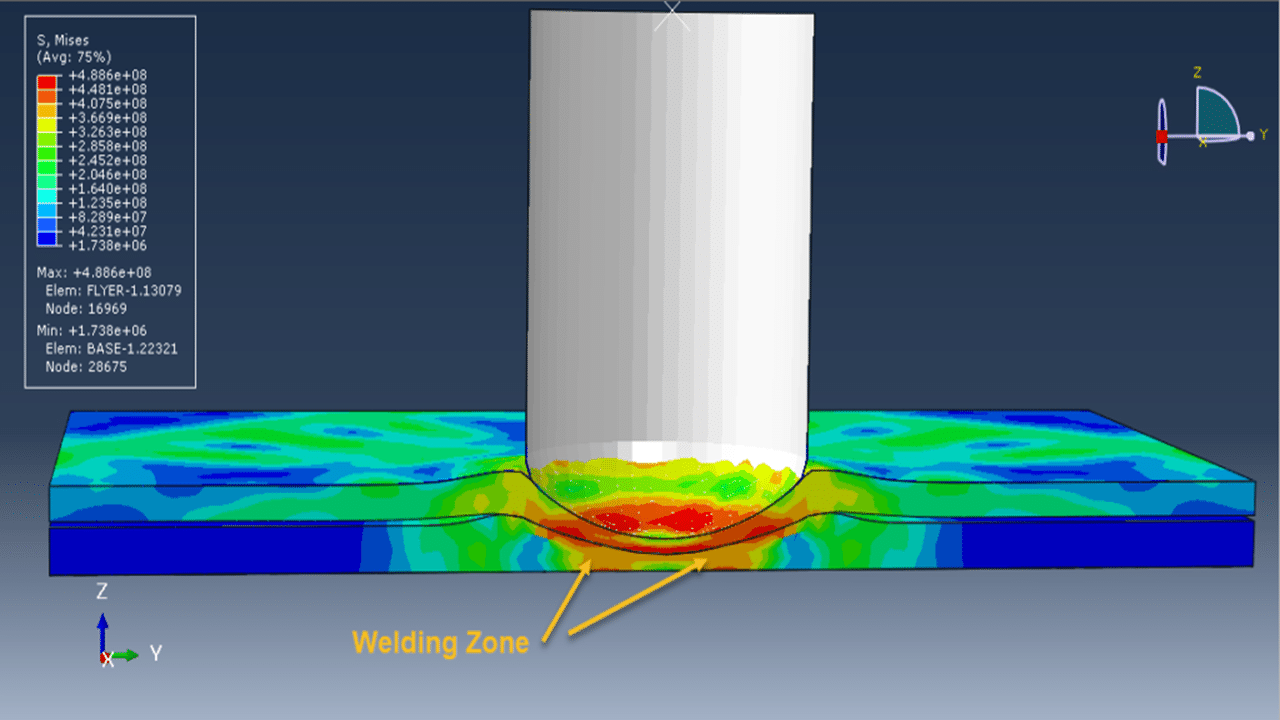

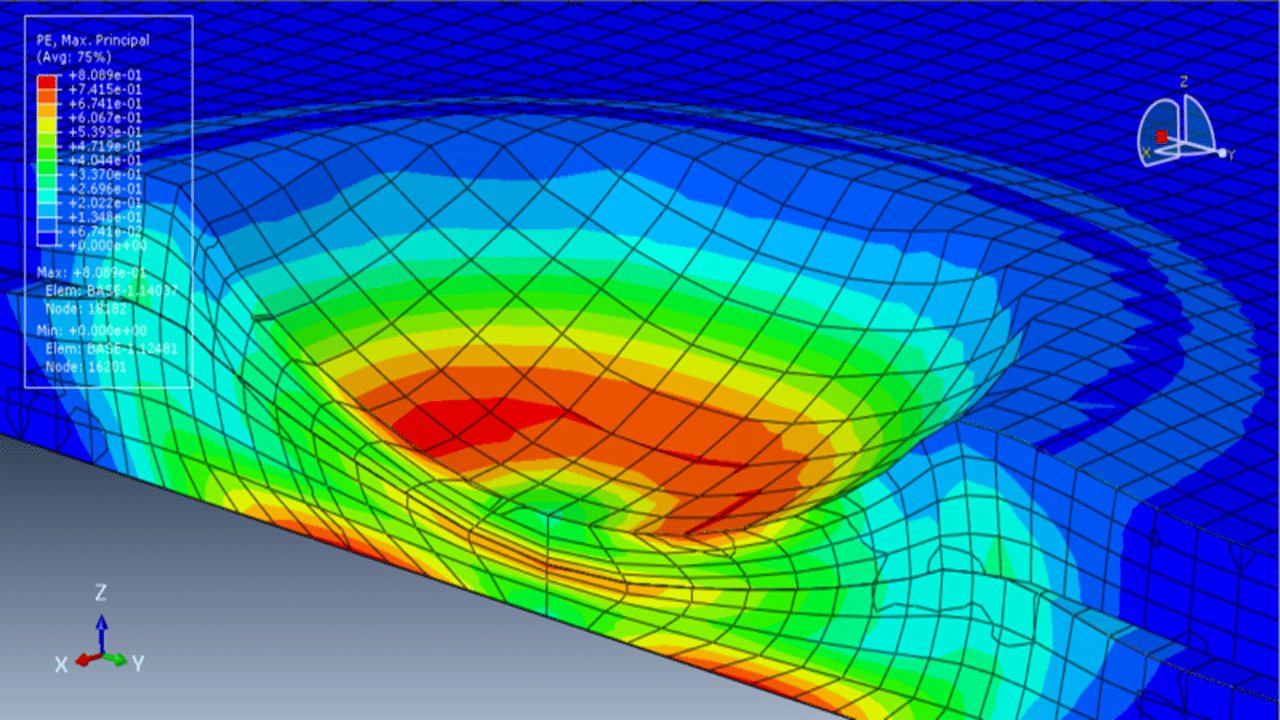

The Johnson-Cook plasticity and damage model is selected to simulate steel behavior. This model, a variation of the Mises plasticity model, incorporates hardening laws and strain-rate dependence suitable for metals under high-strain-rate deformation. Material data are sourced from relevant literature. The dynamic explicit step is appropriate for this analysis. Surface-to-surface contact is defined between the rigid projectile and the flyer plate, and between the flyer and base plates with specific contact properties. Fixed boundary conditions are applied to the outer edges of the plates, and an initial velocity is assigned to the projectile. A fine mesh is necessary for accurate results.

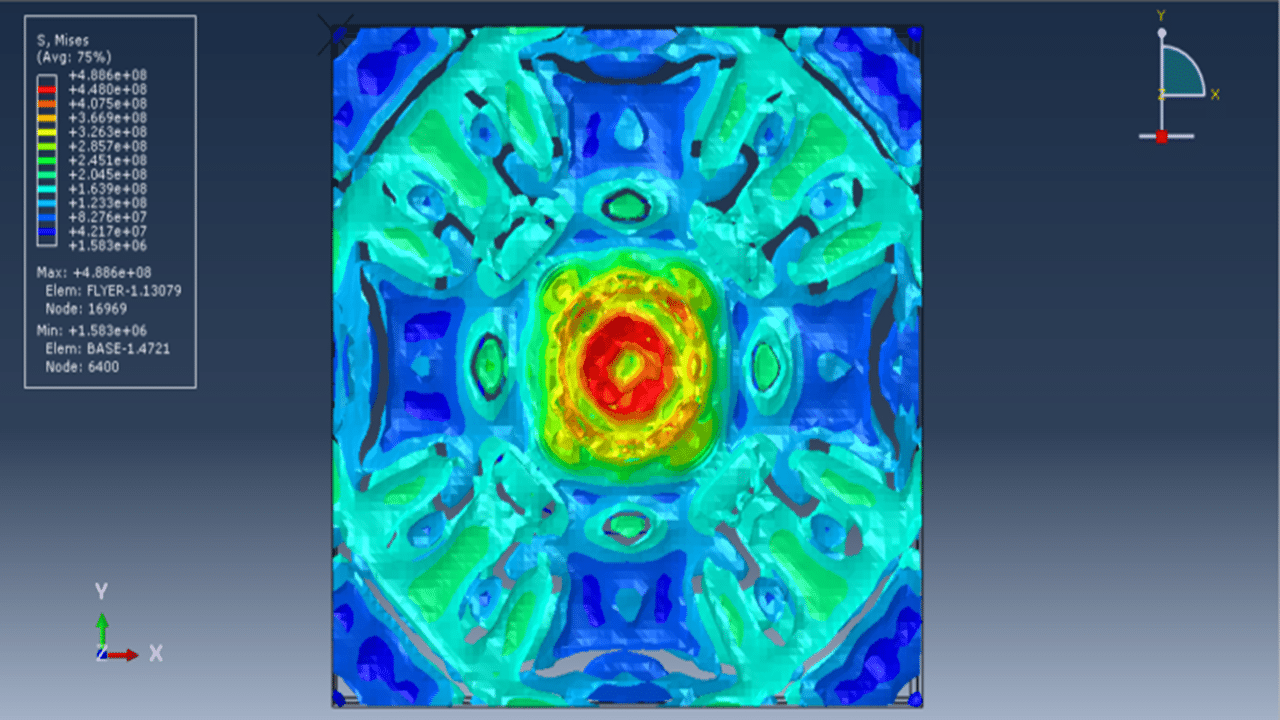

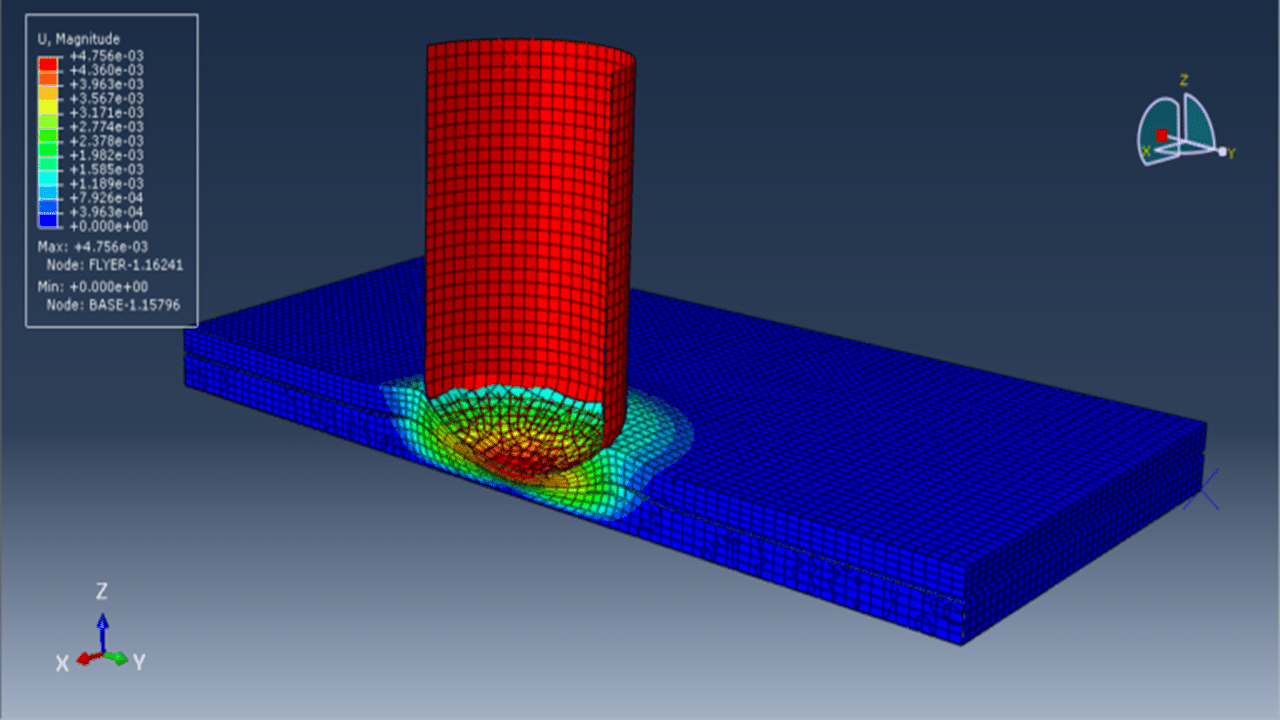

After simulation, results such as stress, strain, and the contact zone are available for analysis.

Let’s Learn and Collaborate

Get VIP access to new content.

Sign up for weekly deals and news.

Engineering Downloads is a hub for learning,

collaboration, and sharing engineering models

and resources.

© 2025 Engineering Downloads. All rights reserved.

Want to receive push notifications for all major on-site activities?