Product Overview:

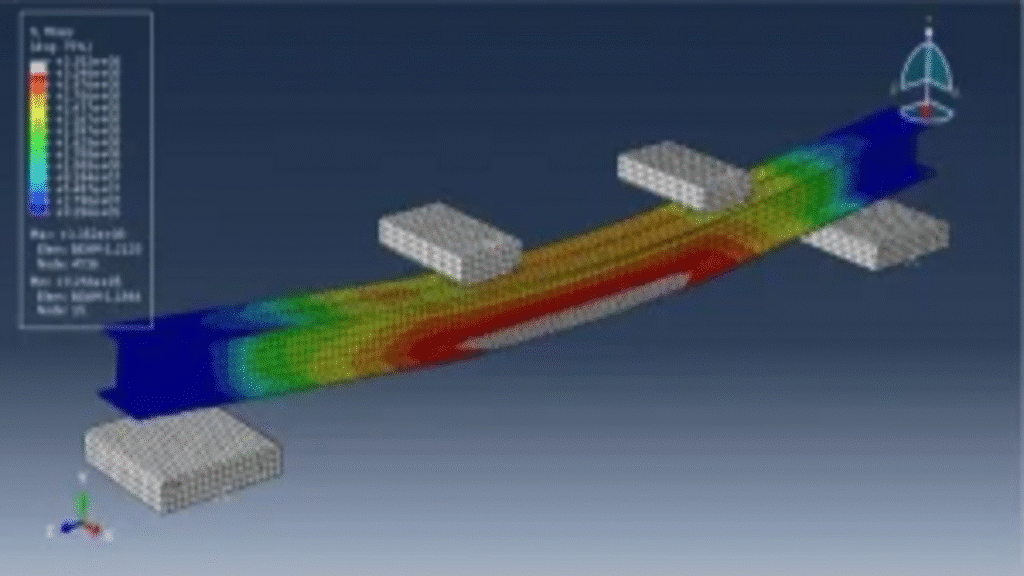

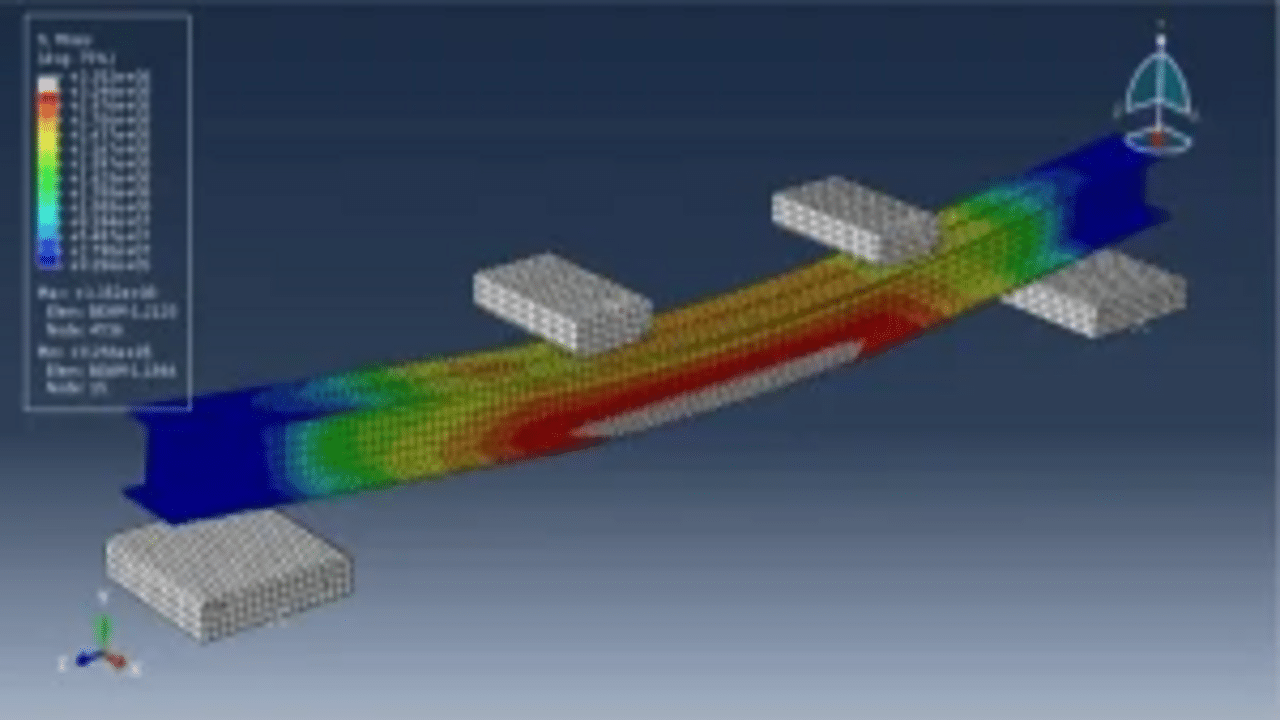

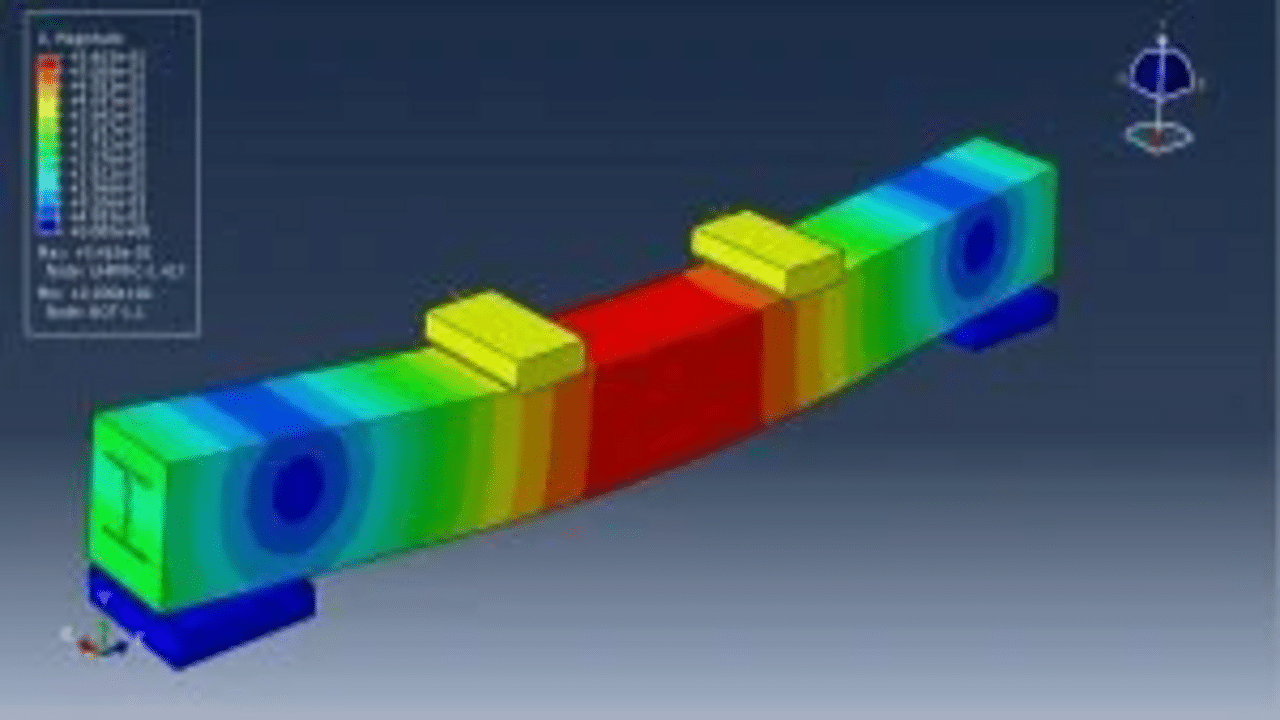

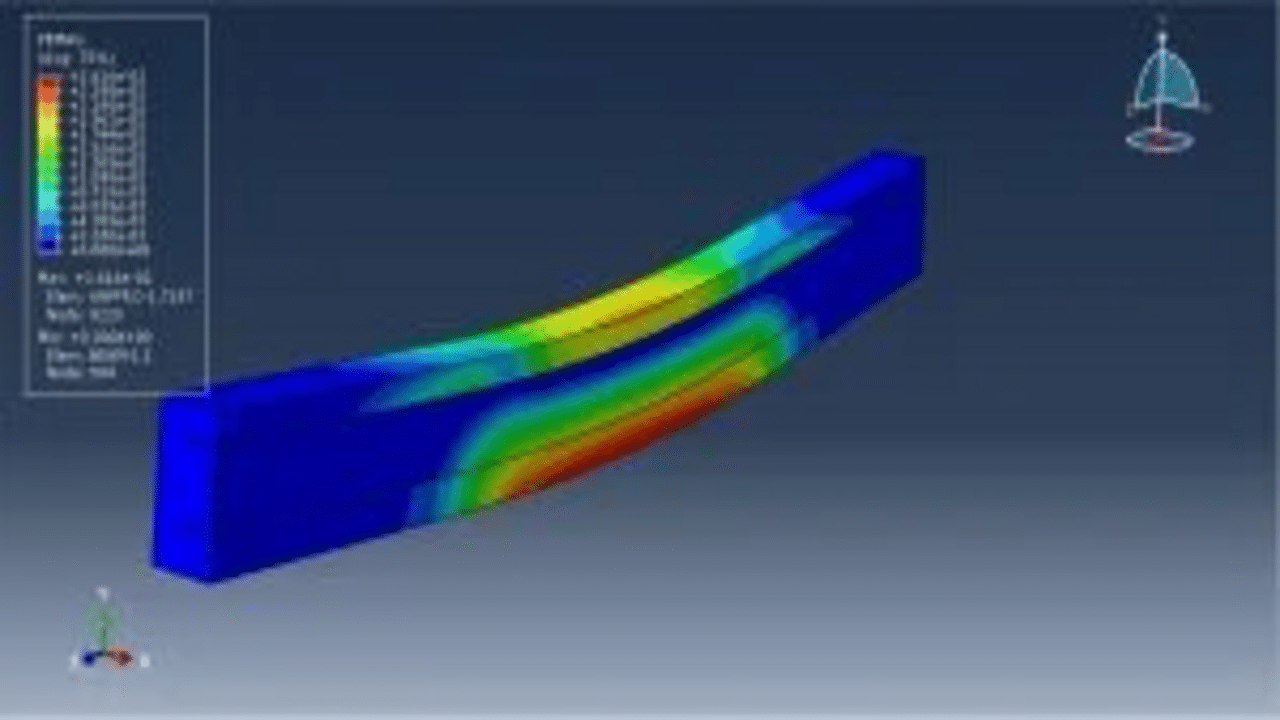

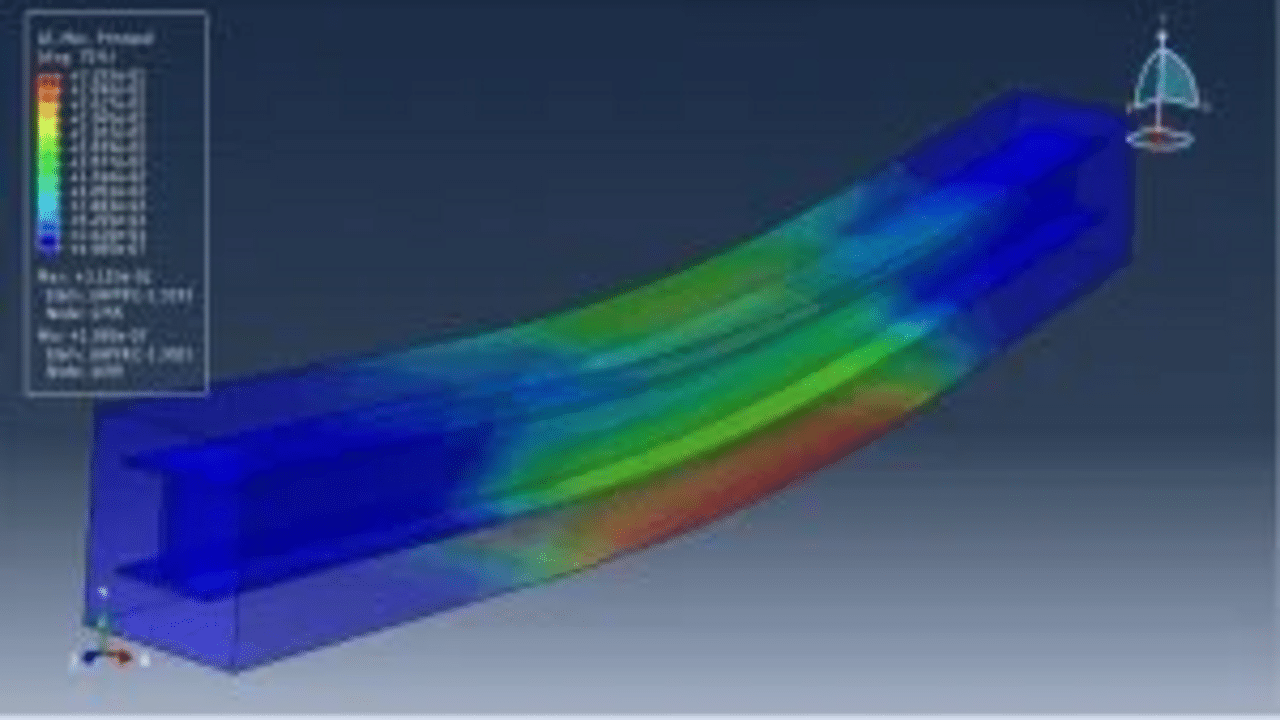

This tutorial outlines the simulation of four-point bending of Ultra High Performance Concrete (UHPC) beams that incorporate a steel beam core, conducted using Abaqus. UHPC is known for its remarkable compressive strength exceeding 21.7 ksi (150 MPa) and a flexural strength surpassing 0.72 ksi (10 MPa) after a curing period of 28 days. The UHPC concept was initially introduced by Richard and Cheyrezy and was developed in the early 1990s at the Bouygues Laboratory in France. This simulation utilizes the mechanical properties of both plain and fiber-reinforced UHPC mixtures made from commercially available materials. In the model, the UHPC beam is represented as a three-dimensional solid part, while the steel beam core is also modeled as a three-dimensional solid. Rigid bodies act as boundary zones, and hydraulic jacks are modeled as rigid shell components.

The Concrete Damaged Plasticity model is employed to characterize the UHPC beam’s behavior. This model is a continuum-based plasticity and damage framework that accounts for the primary failure mechanisms of tensile cracking and compressive crushing in concrete. Material properties are derived from relevant literature. For the steel beam core, elastic-plastic material properties along with a ductile damage criterion are utilized to predict damage during the bending process. The simulation uses a general static step with specific adjustments to improve convergence. Surface-to-surface contact with friction is implemented as the contact property between the rigid bodies and the concrete beam; the interaction between the steel core and the UHPC beam is treated as ideal contact. Fixed boundary conditions are assigned to the two bottom rigid bodies, while a displacement is applied with a specified amplitude to the top two rigid bodies. A fine mesh is essential to achieve accurate simulation results.

Upon completion of the simulation, various results—including stress, strain, damage metrics, and force-displacement diagrams—can be analyzed.

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

Abaqus

€75,00 €37,00

Abaqus

€76,00 €38,00

Abaqus

€79,00 €38,00

See more

Want to receive push notifications for all major on-site activities?