Packages & Tutorials

Engineering Files & Tools

Software

Ready-to-use Models (FEA/CFD)

Excel Sheets & Hand Calculations

Product Overview:

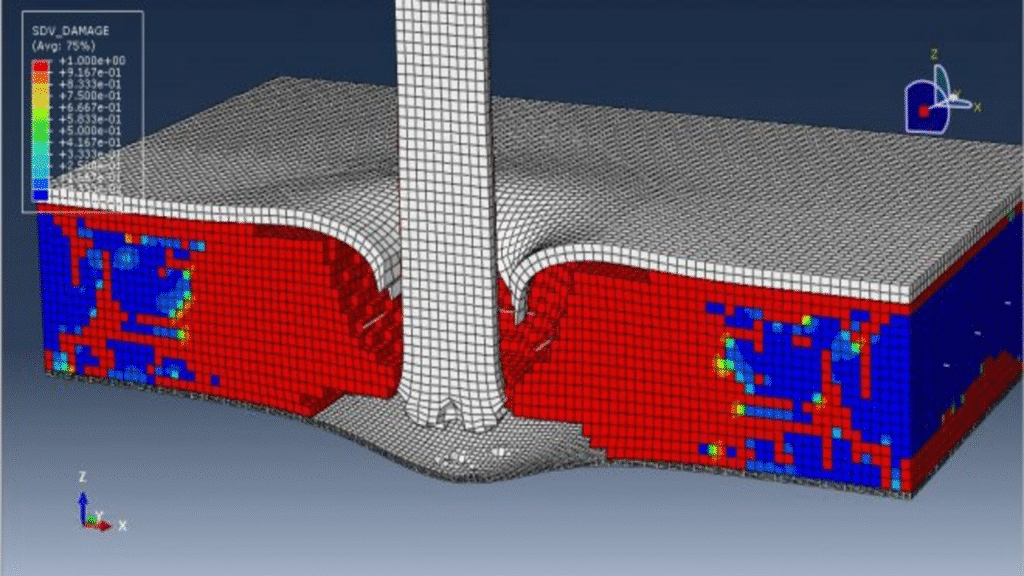

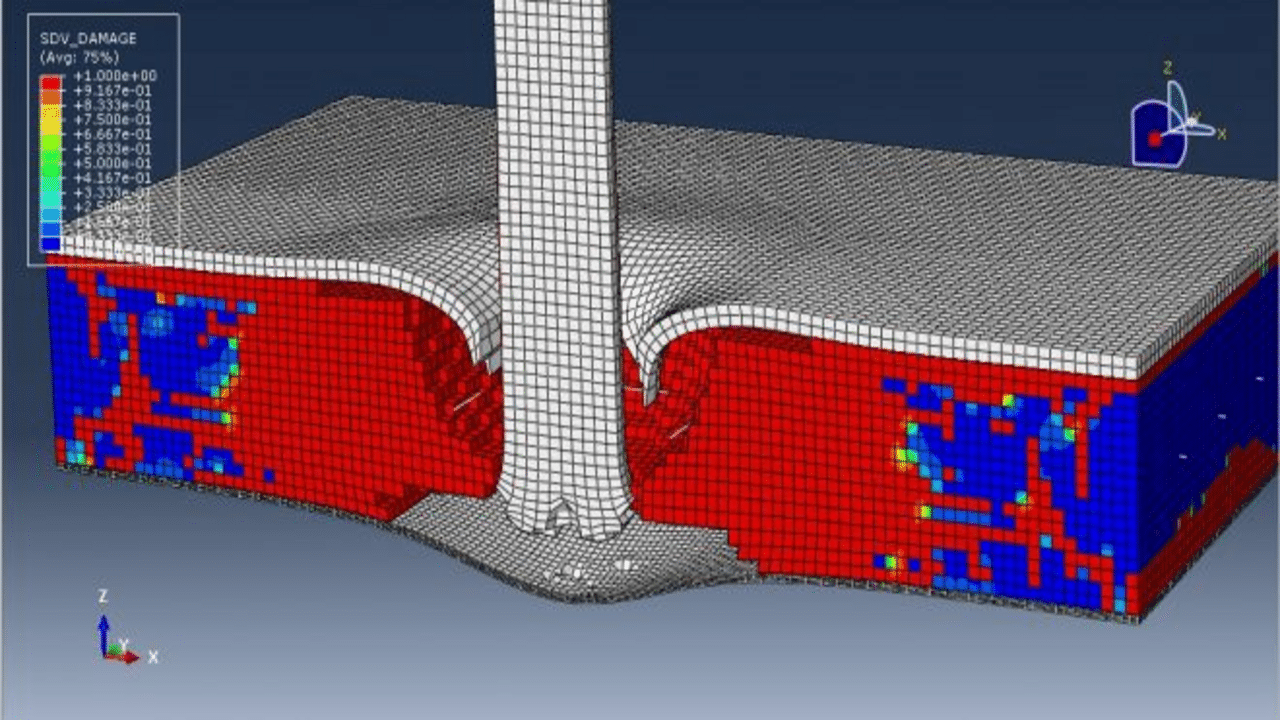

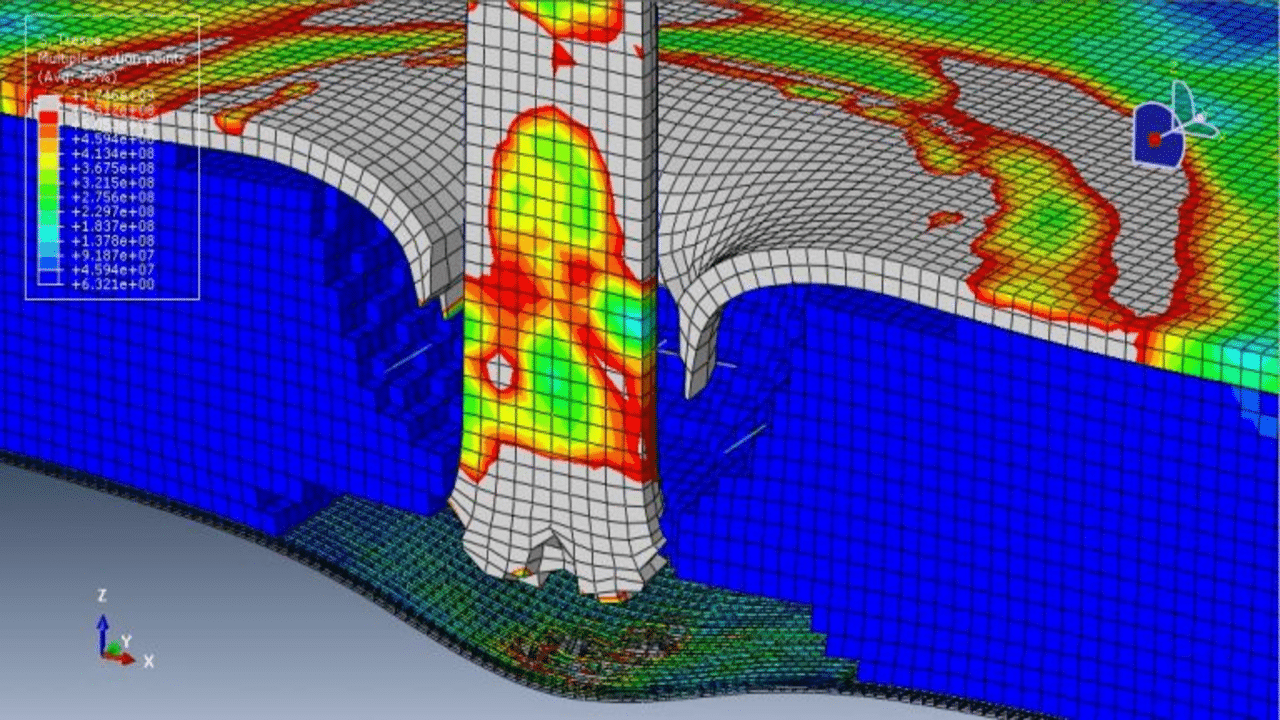

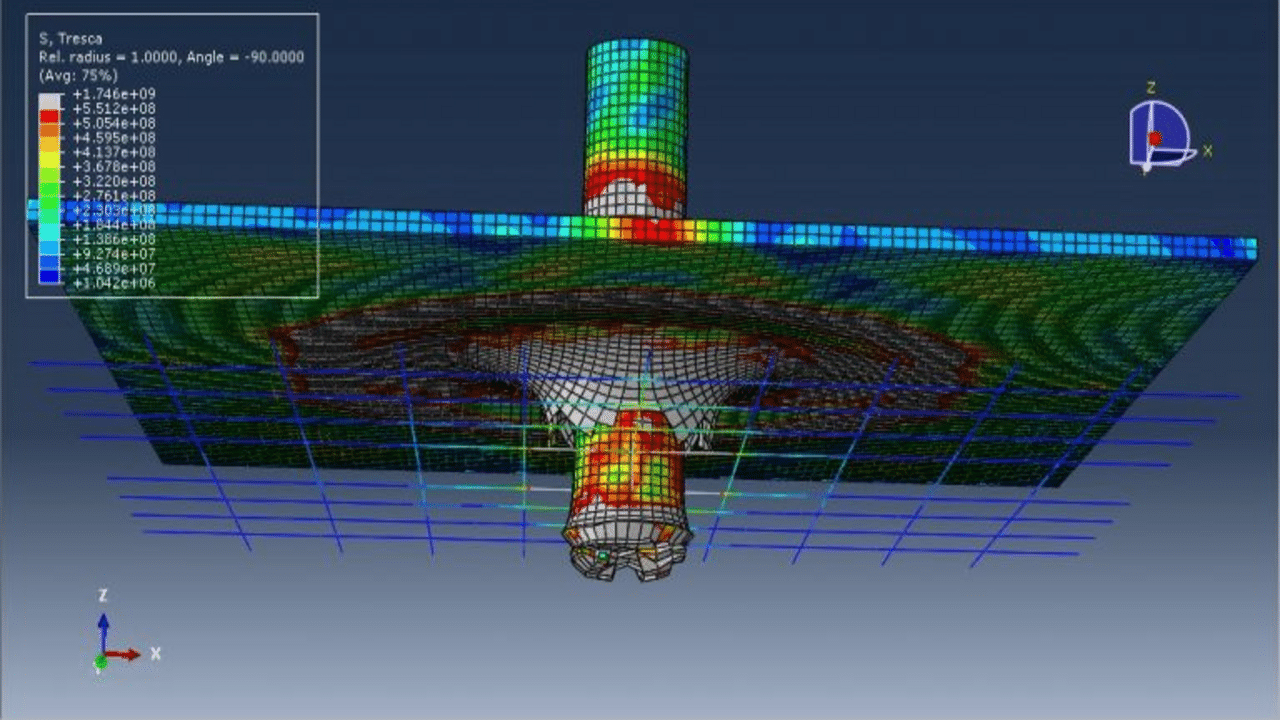

In this tutorial, we explore the simulation of a high-velocity steel projectile impacting a composite panel consisting of steel, concrete, and epoxy glass layers using Abaqus. The steel projectile is represented as a cylindrical solid part, while the steel plate (the panel’s top layer), the concrete middle layer, and the composite layers are all modeled as three-dimensional components. The composite layers are handled with a continuum shell technique, and the beam structure is modeled as a wire part.

To accurately simulate material behavior and damage progression, the composite layers incorporate Hashin’s damage criteria with damage evolution. The elastic properties of the epoxy-glass lamina, including failure stress, are also modeled. For the concrete layer, the JH2 material model is used, allowing for precise calculations of damage and failure in brittle materials when subjected to high-velocity impacts.

The simulation employs the dynamic explicit step method, utilizing a general contact procedure. Perfect contact is assumed between the steel plate and concrete, as well as between the concrete and the first composite layer. To account for interaction within the composite layers, cohesive surface contact properties with damage parameters are applied. The beam structure is embedded within the concrete host. Symmetry boundary conditions are imposed on symmetric surfaces, while fixed boundaries are applied to the panel’s sides. The steel projectile is assigned an initial velocity, and a fine mesh is used to ensure accurate results.

Upon completion of the simulation, a range of outputs, including stress, strain, damage propagation, and failure data, can be obtained.

Dynamic

€1,00 €0,00

See more

Want to receive push notifications for all major on-site activities?