Concrete structures are increasingly being exposed to extreme loading conditions, including high-velocity impacts resulting from accidents, explosions, or ballistic threats. Traditional concrete, while strong in compression, suffers from brittleness and poor resistance to dynamic loads. To overcome these limitations, researchers have developed hybrid fiber-reinforced concrete (HFRC), which incorporates a combination of different fiber types—typically steel, polypropylene, glass, or basalt—to enhance both the ductility and toughness of the composite.

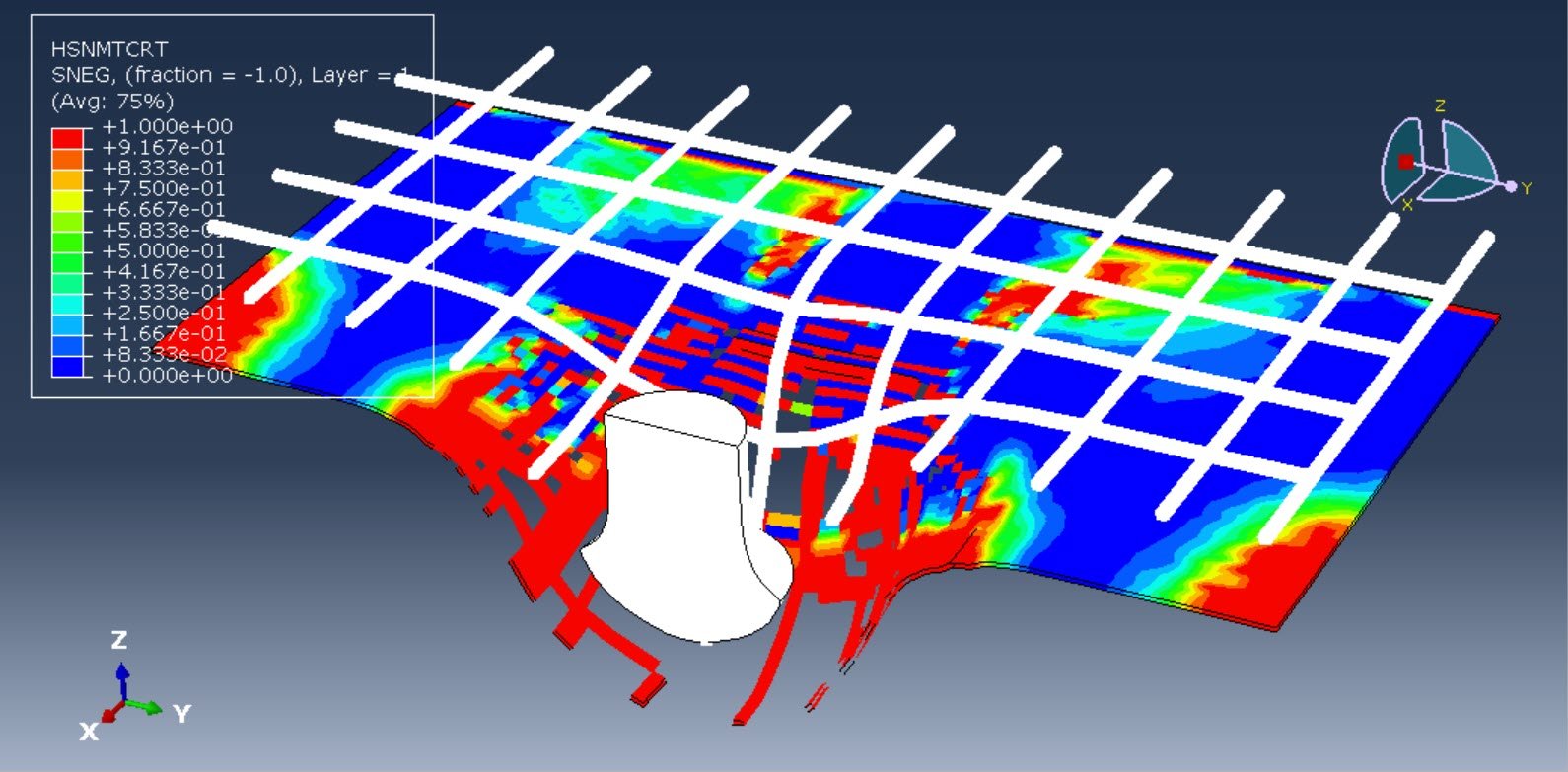

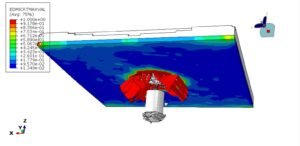

To further improve the impact resistance and post-crack performance of HFRC, carbon fiber-reinforced polymer (CFRP) materials are often externally bonded or embedded as reinforcement. CFRP offers high tensile strength, lightweight characteristics, corrosion resistance, and excellent energy absorption capacity, making it an ideal candidate for structural strengthening under dynamic conditions.

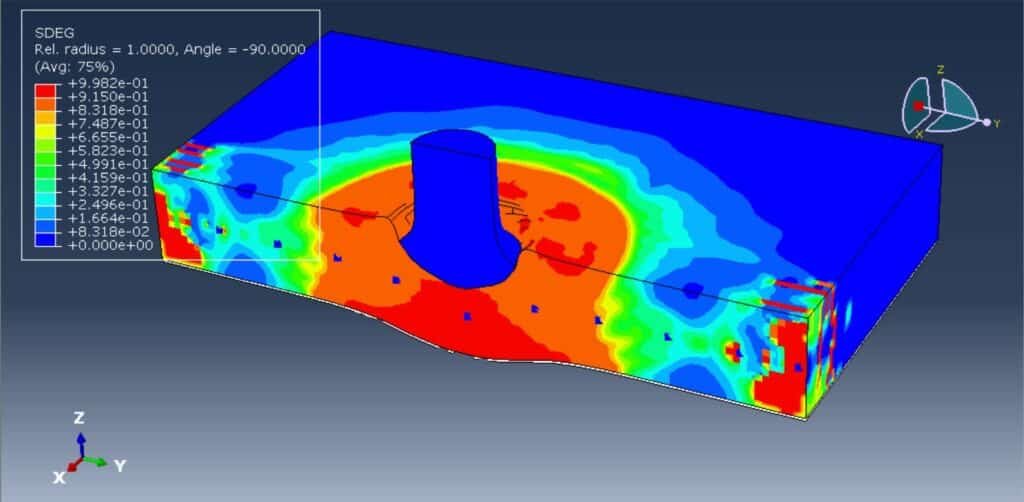

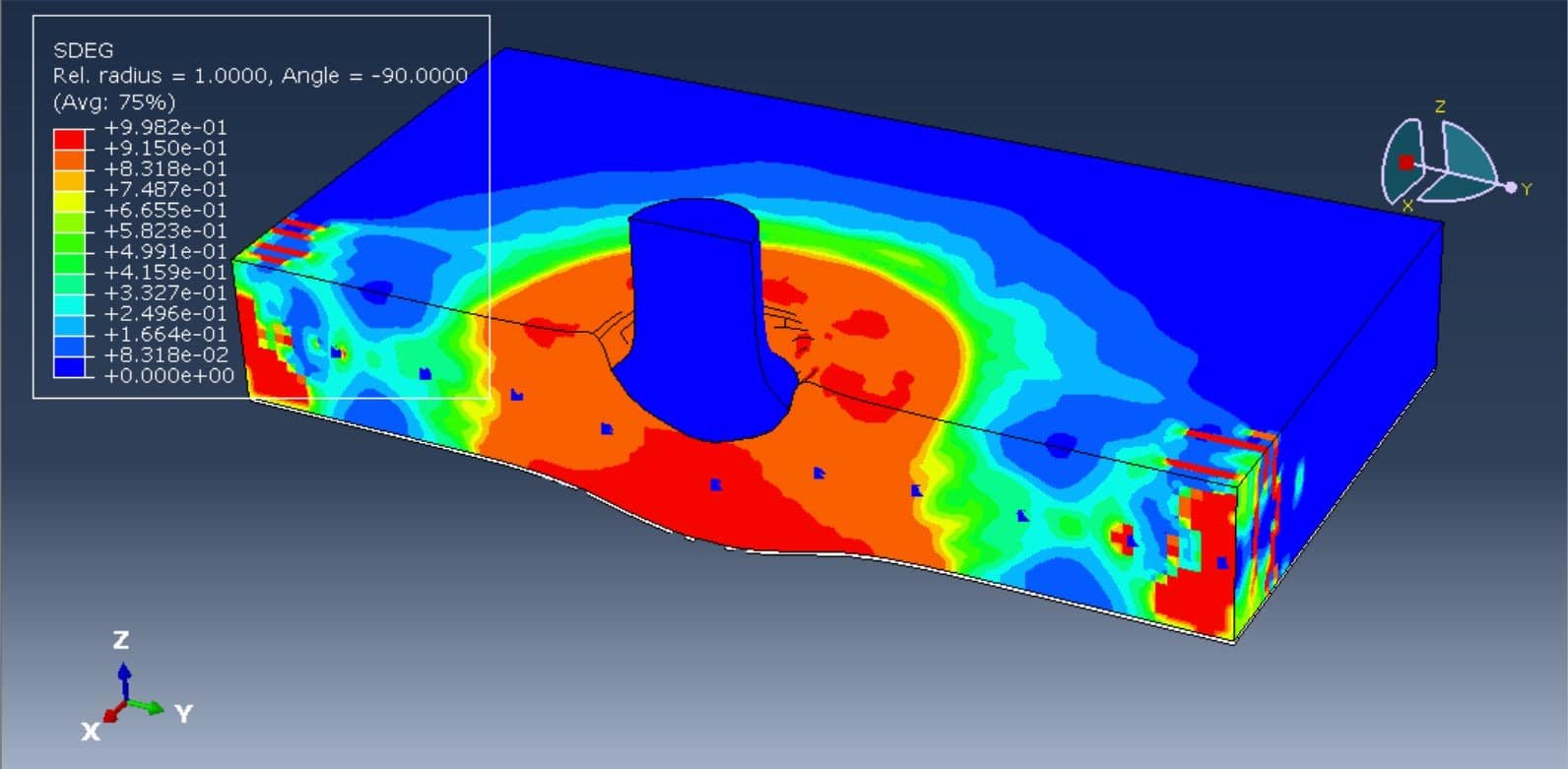

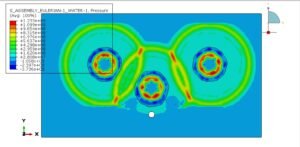

The use of numerical simulation techniques, particularly through finite element analysis (FEA), provides a powerful tool to predict and analyze the behavior of HFRC panels reinforced with CFRP under high-velocity impact loading. These simulations aid in understanding complex failure mechanisms, optimizing material compositions, and designing effective reinforcement layouts, eliminating the need for costly full-scale experiments.

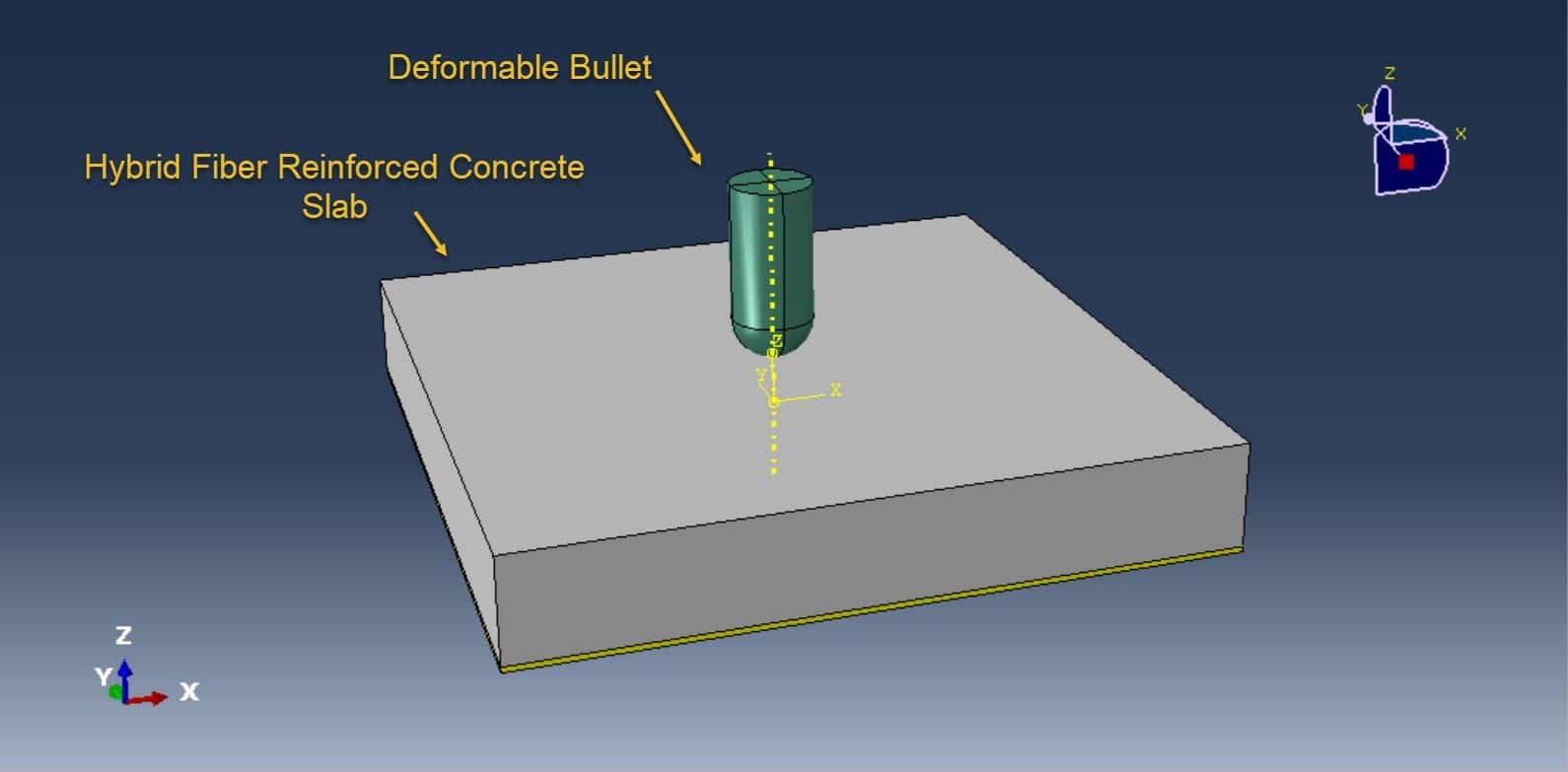

This study aims to investigate the dynamic response, failure patterns, and energy absorption characteristics of HFRC panels strengthened with CFRP when subjected to high-velocity projectile impact. By developing a validated finite element model, key parameters such as fiber type and volume, CFRP layout, impact velocity, and projectile characteristics can be systematically evaluated. The outcomes provide valuable insights for the design of resilient infrastructure and protective systems in defense, transportation, and civil engineering applications.

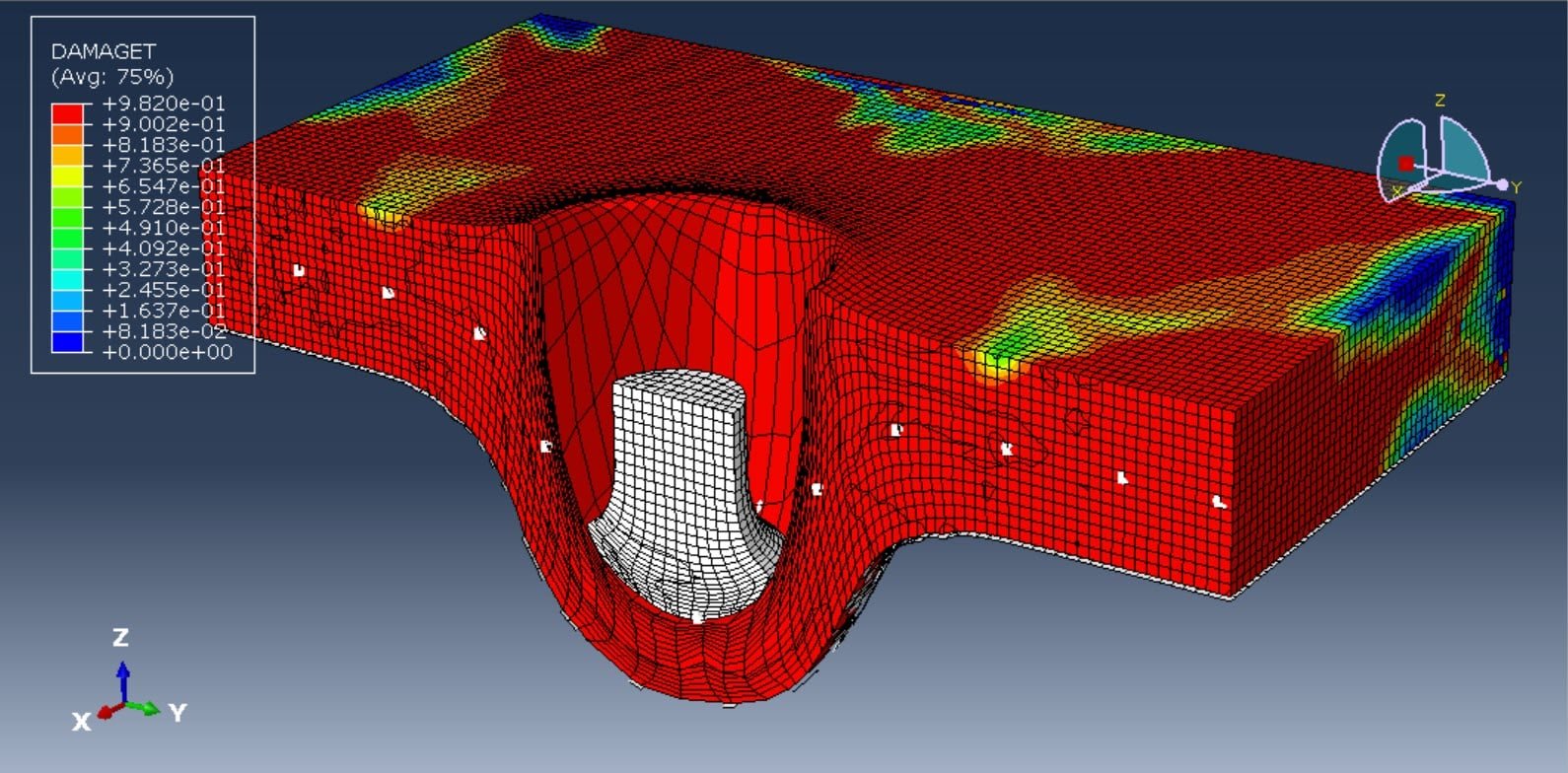

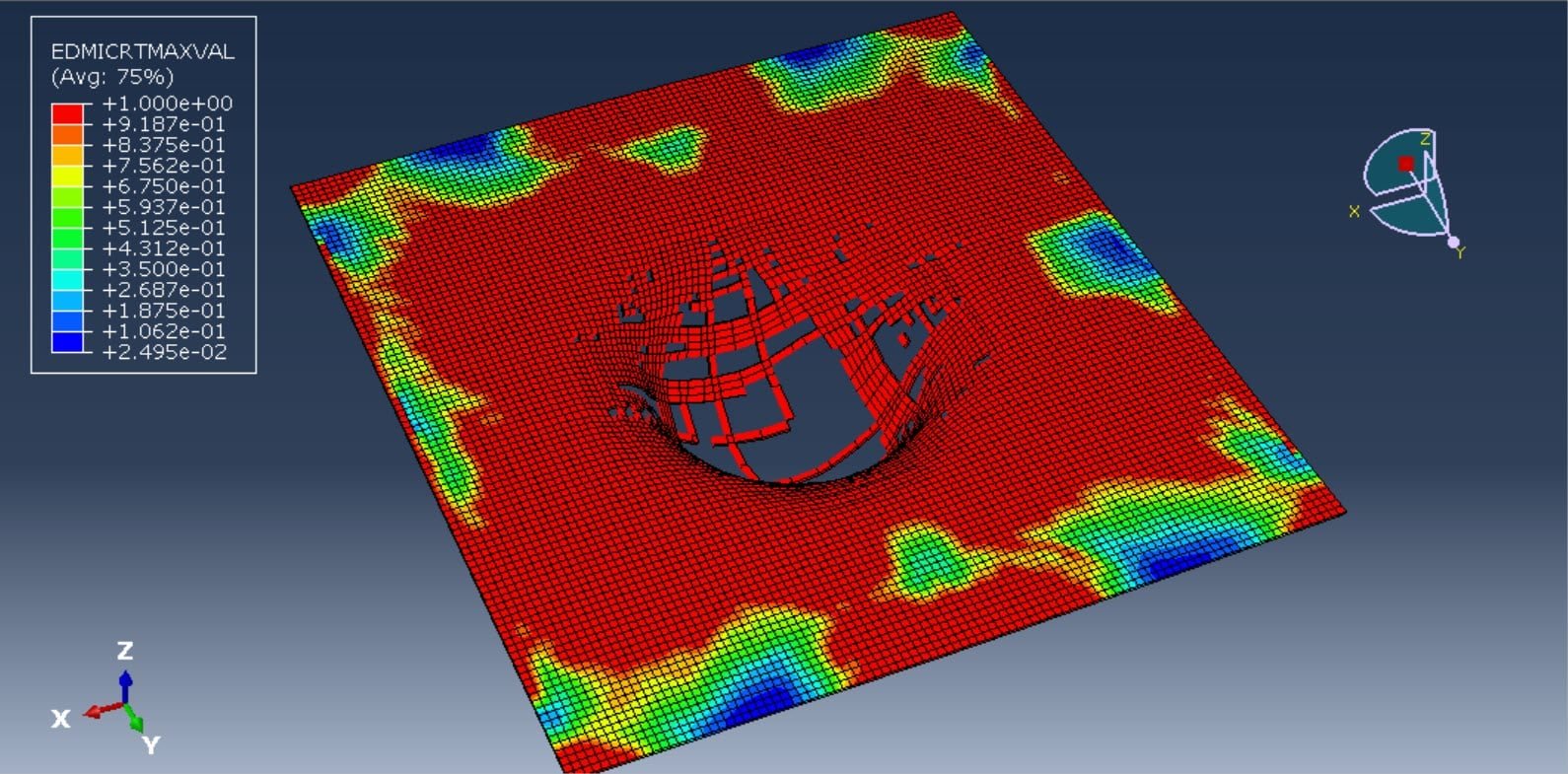

The Concrete Damaged Plasticity(CDP) material model is selected to demonstrate the tension and compression damage of the HFRC panel; the material data are extracted from the paper” Finite element modeling of steel-polypropylene hybrid fiber reinforced concrete using modified concrete damaged plasticity “, this paper represents the HFRC material model.

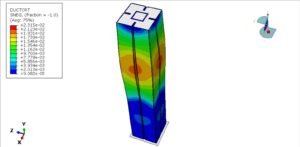

During the analysis, you will learn all details about the HFRC panel, CFRP reinforcement, and deformable steel bullet.

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

Abaqus

€75,00 €37,00

Abaqus

€76,00 €38,00

Abaqus

€79,00 €38,00

See more

Want to receive push notifications for all major on-site activities?