Product Overview:

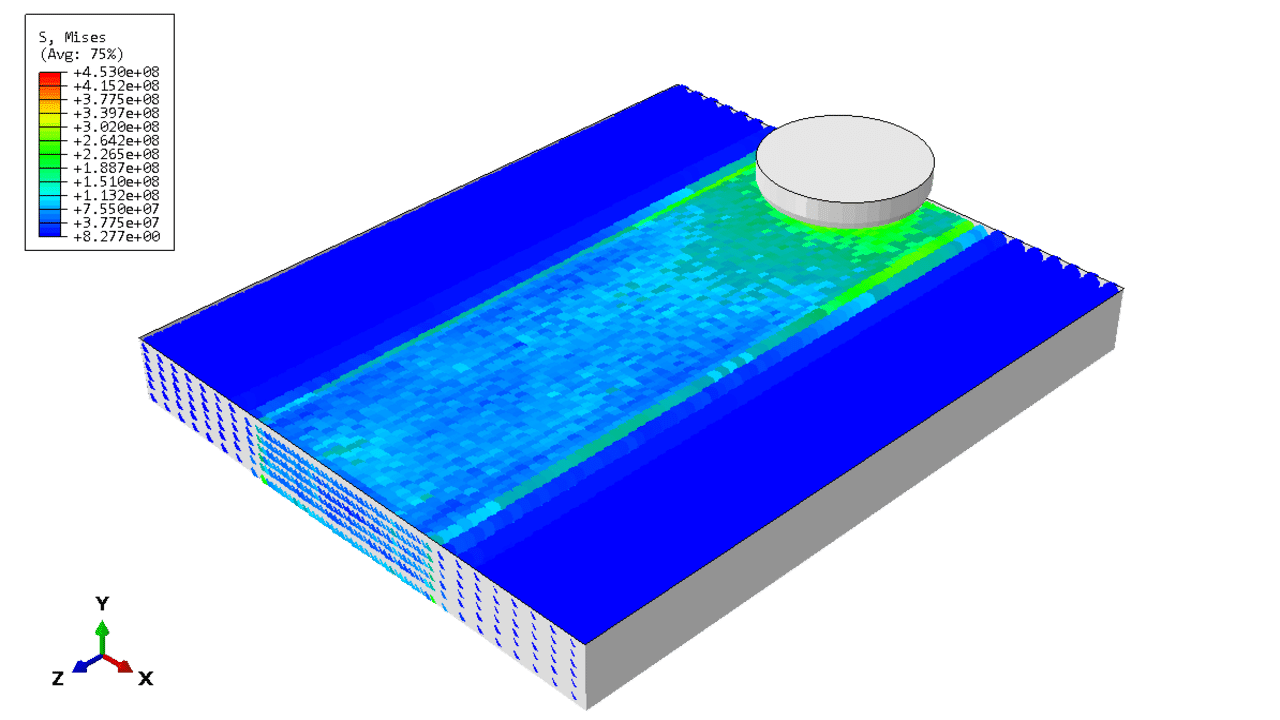

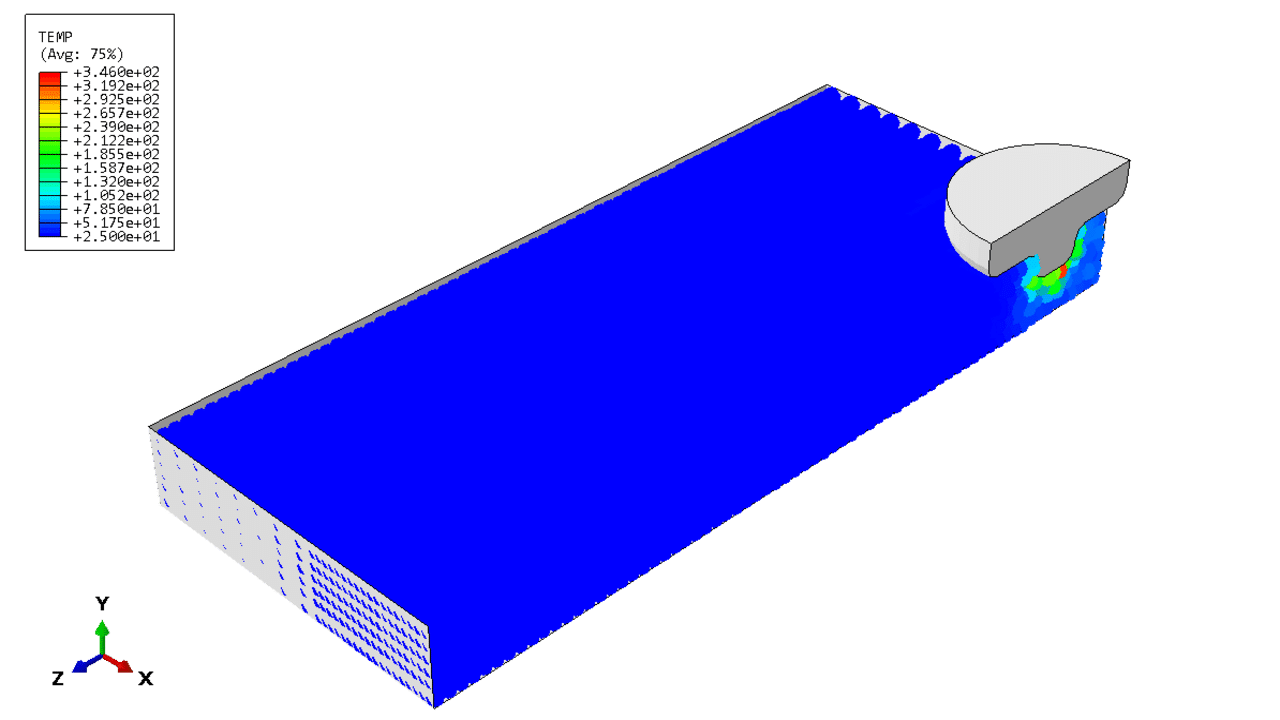

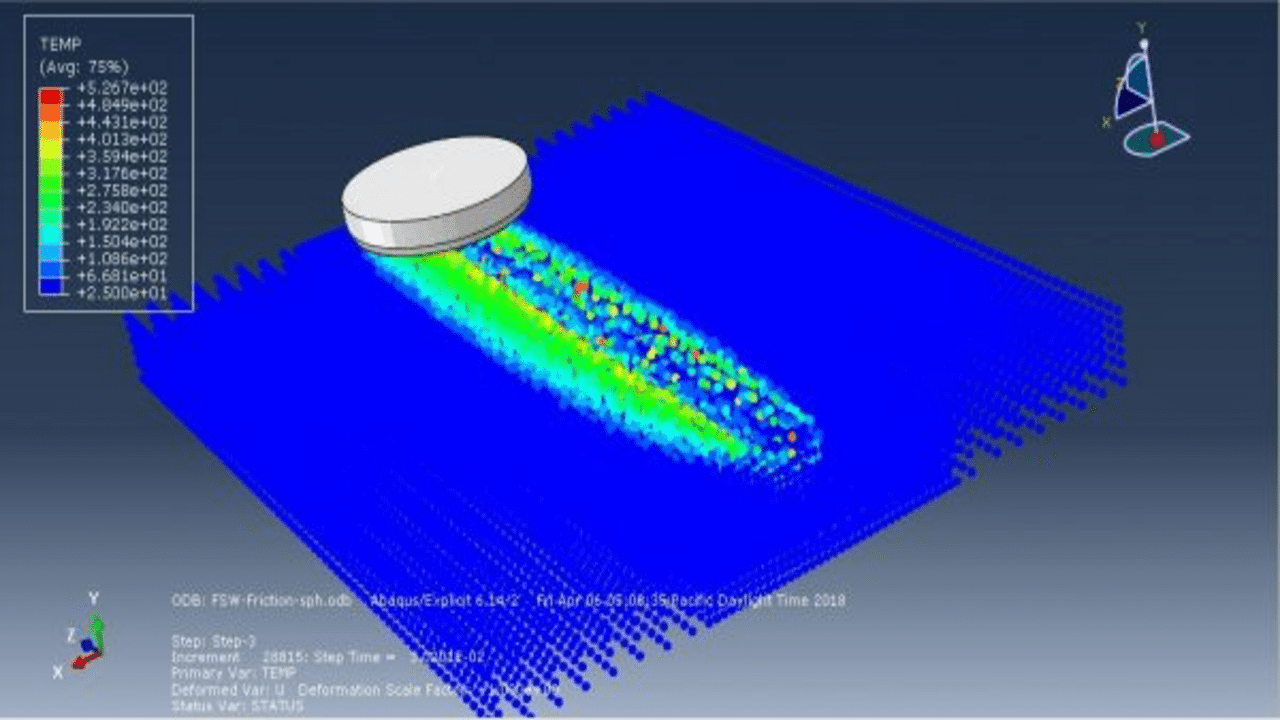

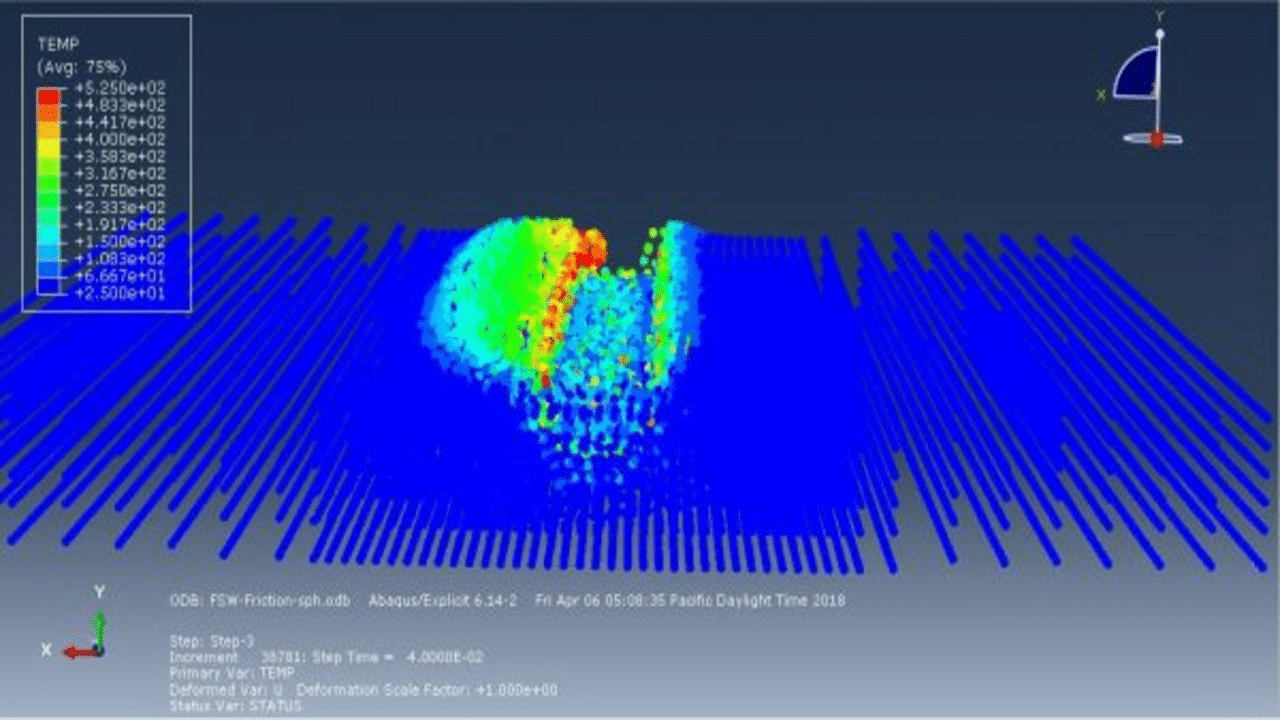

Friction Stir Welding (FSW) is rapidly becoming the preferred method for joining aluminum alloys, offering high-quality welds at fast production rates. Unlike conventional fusion welding, FSW is a solid-state process that avoids many defects related to melting and solidification. However, under certain process parameters, FSW joints can still develop volumetric defects that may weaken the weld. In this simulation, the Smoothed Particle Hydrodynamics (SPH) method is utilized to model FSW in Abaqus, incorporating thermal analysis. Since Abaqus does not directly support SPH elements coupled with temperature using PC3DT elements, modifications were made to apply temperature to these elements. The analysis is divided into three steps, tracking changes in both stress and temperature throughout the process.

Key Topics:

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?