Introduction to the Flexural Behavior of Steel-Polypropylene Hybrid Fiber Reinforced Concrete Reinforced with GFRP Sheet

Overview

The flexural behavior of Steel-Polypropylene Hybrid Fiber Reinforced Concrete (SP-HyFRC) reinforced with Glass Fiber Reinforced Polymer (GFRP) sheets represents an innovative approach in modern construction materials engineering. This composite system combines the benefits of fiber-reinforced concrete (FRC) with external GFRP strengthening to enhance structural performance, durability, and sustainability.

Key Components

1. Steel-Polypropylene Hybrid Fiber Reinforced Concrete (SP-HyFRC)

Steel fibers improve tensile strength, crack resistance, and ductility.

Polypropylene fibers enhance impact resistance, reduce plastic shrinkage cracks, and improve post-cracking behavior.

The hybrid combination synergizes the advantages of both fibers, leading to better mechanical properties than single-fiber systems.

2. Glass Fiber Reinforced Polymer (GFRP) Sheets

GFRP provides high tensile strength, corrosion resistance, and lightweight properties.

When externally bonded to SP-HyFRC, it enhances flexural capacity, stiffness, and crack control.

Research Significance

Improved Flexural Performance: The hybrid fiber reinforcement delays crack propagation, while GFRP sheets provide additional tensile reinforcement, improving load-bearing capacity and deformation characteristics.

Durability & Sustainability: GFRP is corrosion-resistant, making it suitable for harsh environments, while polypropylene fibers reduce long-term maintenance needs.

Applications: Ideal for bridges, marine structures, seismic retrofitting, and other infrastructure requiring high-performance concrete.

Objectives of Study

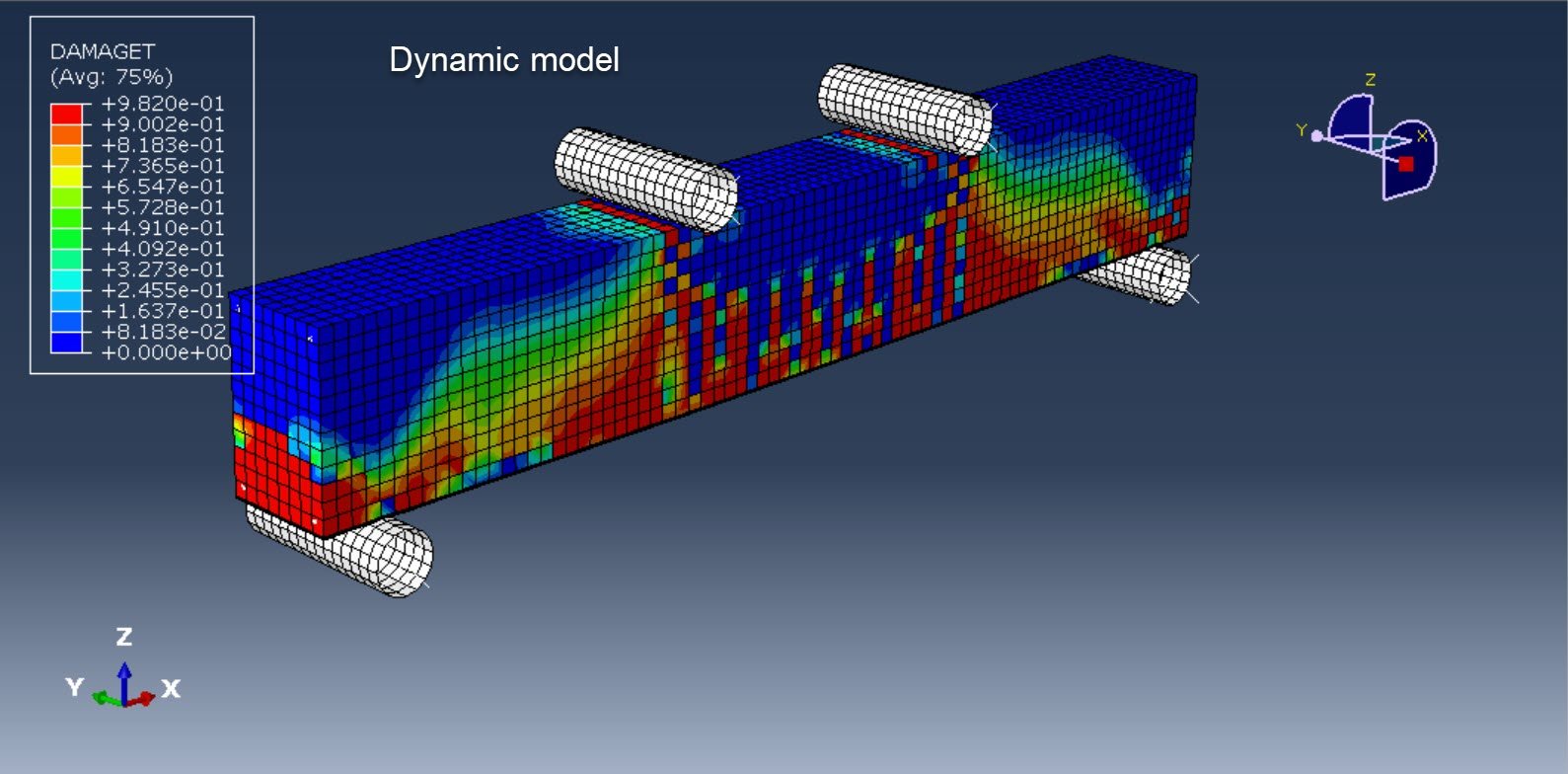

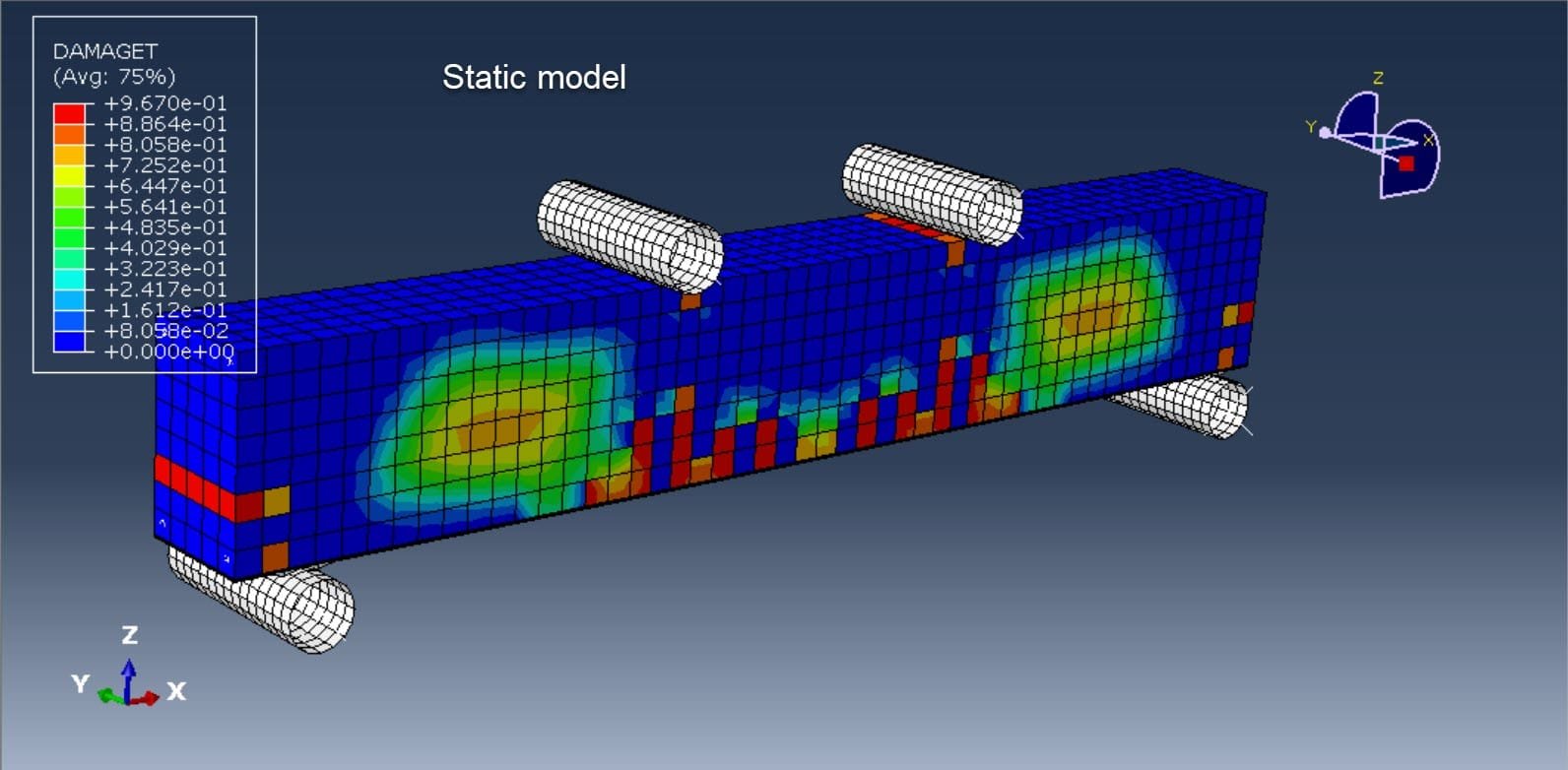

Investigate the flexural strength, crack patterns, and failure modes of SP-HyFRC with GFRP reinforcement.

Compare the performance with conventional reinforced concrete and single-fiber systems.

Optimize fiber ratios and GFRP configurations for maximum structural efficiency.

Conclusion

This research contributes to advancing high-performance concrete technology by integrating hybrid fibers and composite materials, offering a sustainable solution for modern construction challenges.

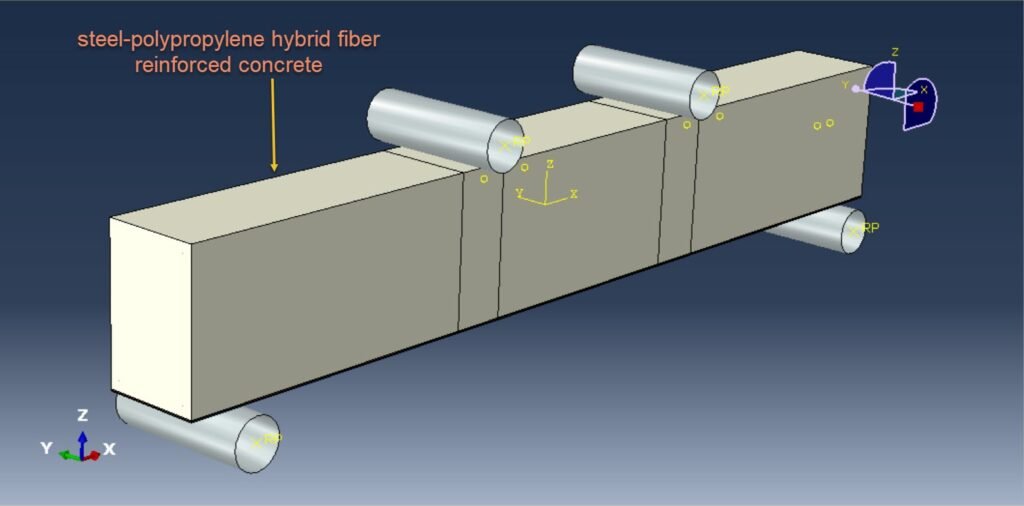

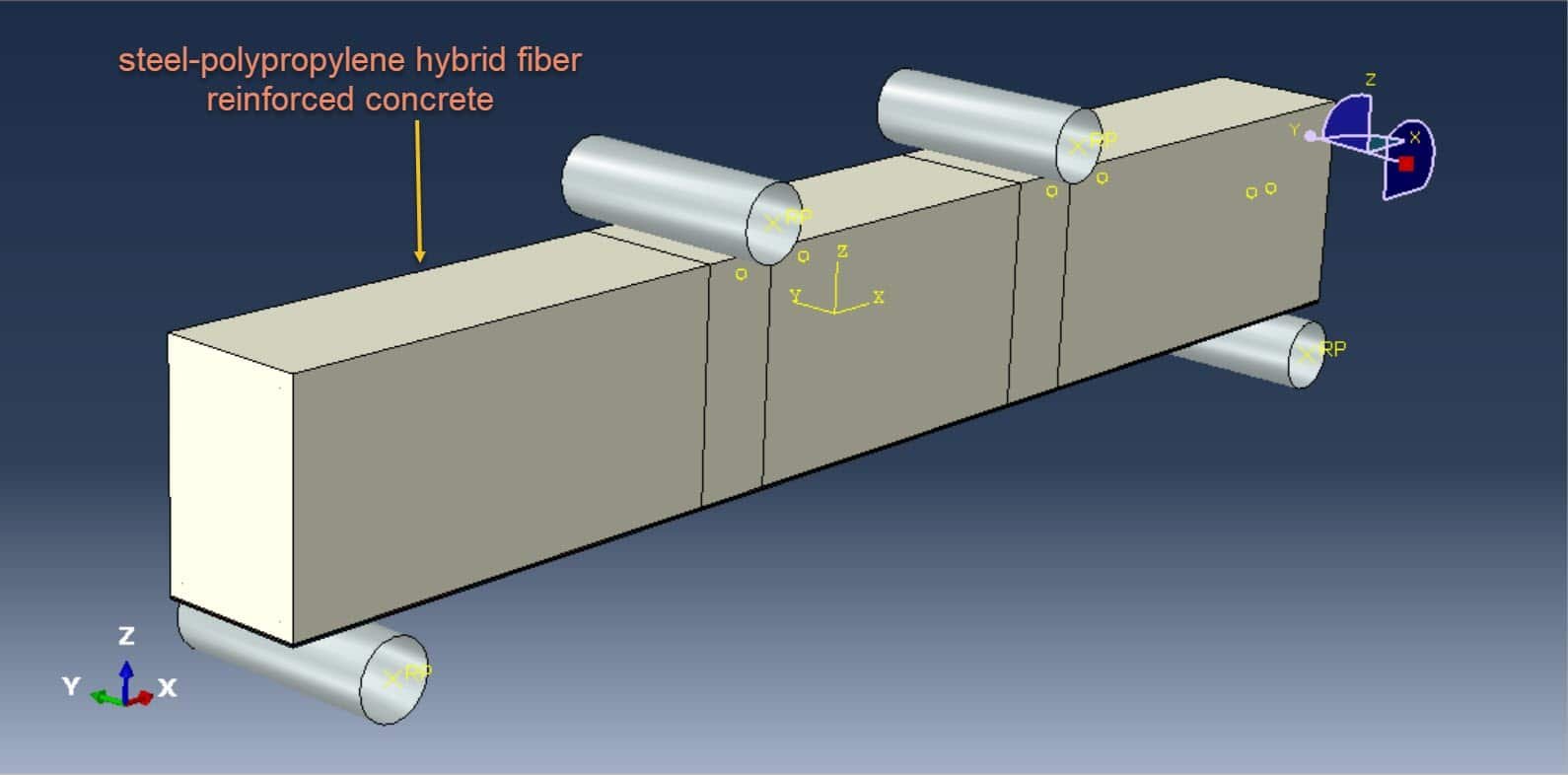

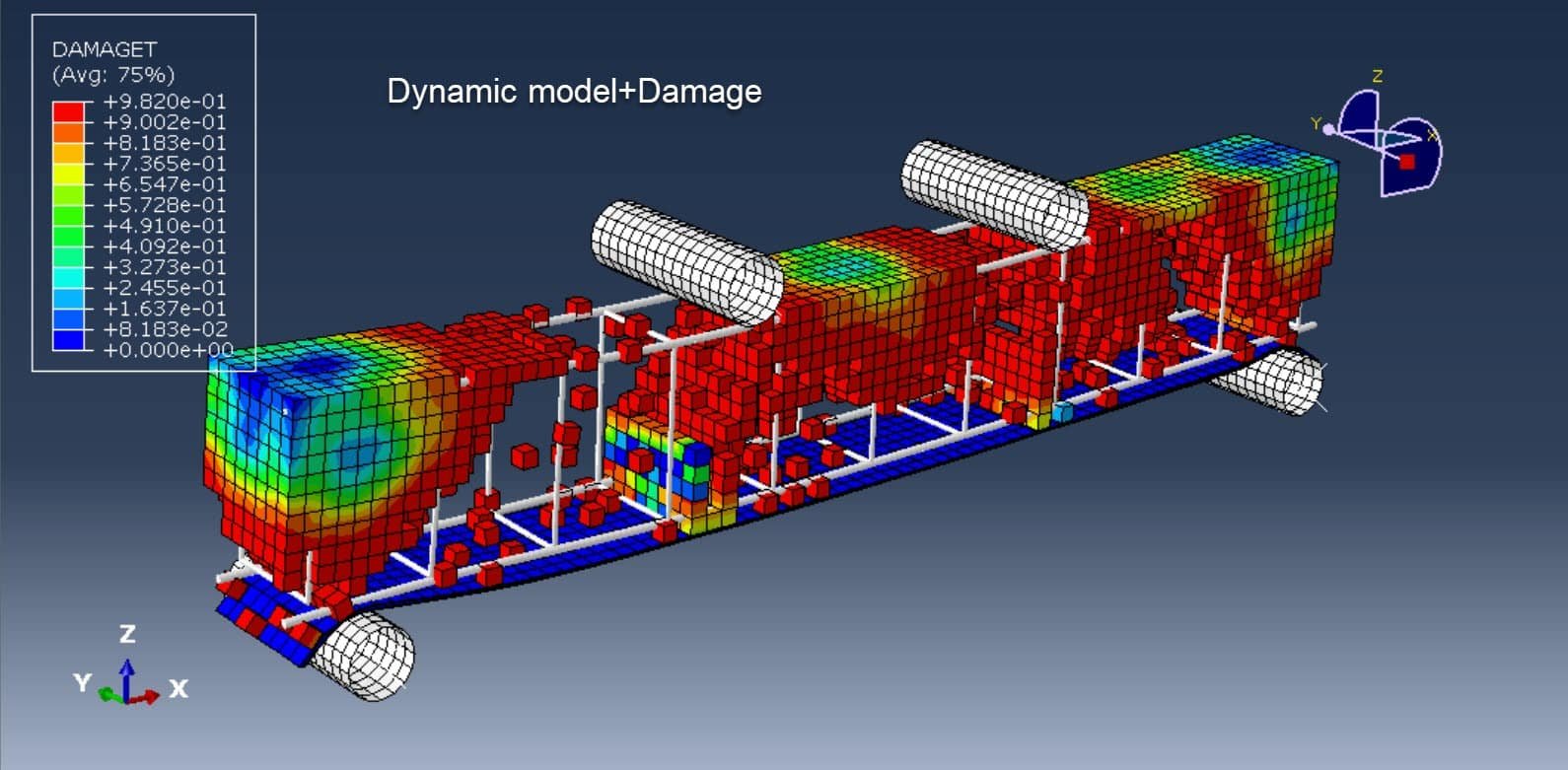

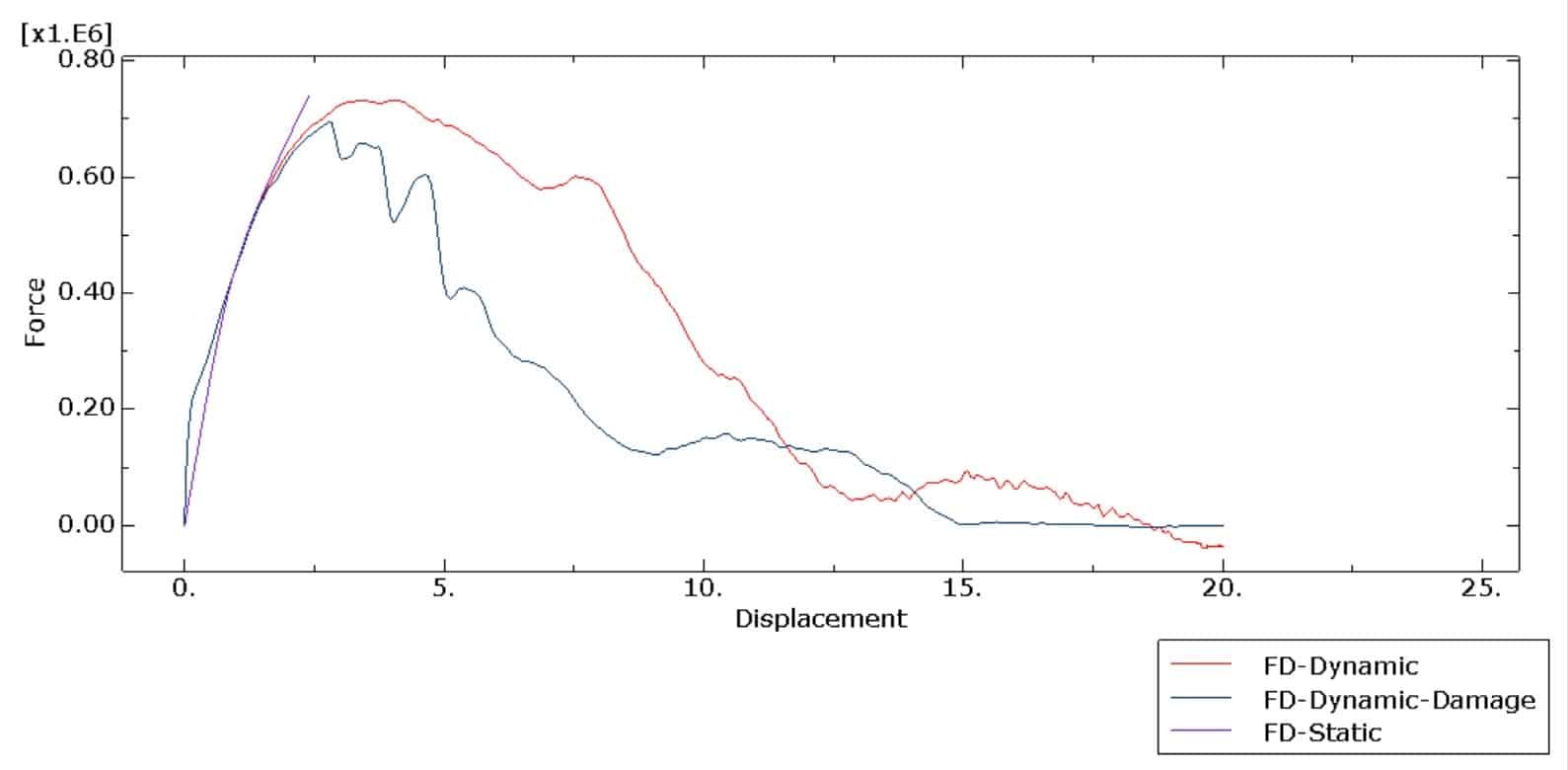

In the present example, the HFRC beam is modeled as a three-dimensional part. Both GFRP and epoxy, as the interface, are modeled as three-dimensional parts. The steel reinforcement is modeled as a wire with plastic behavior. After the analysis, all results such as stress, strain, tension and compression damage, failure, force-displacement diagram, and others are available.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?