Packages & Tutorials

Engineering Files & Tools

Software

Engineering Topics

Ready-to-use Models (FEA/CFD)

Excel Sheets & Hand Calculations

Codes & Scripts

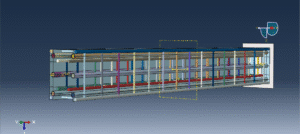

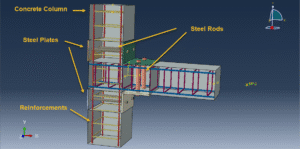

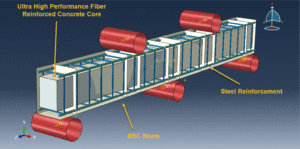

Structures & Materials

Geotechnical & Soil

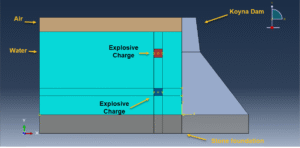

Fluid Dynamics (CFD/FSI)

The concrete cylinder compression test is a standard laboratory procedure used to determine the compressive strength of concrete. It involves applying a uniaxial compressive load to a concrete cylinder specimen until failure occurs. This test is fundamental in civil engineering, as compressive strength is one of the most critical properties of concrete, directly influencing structural integrity.

With advancements in computational tools and finite element analysis (FEA), simulation of the concrete cylinder compression test has become a valuable complement to physical testing. Simulation enables engineers and researchers to analyze stress distribution, crack development, and failure modes under controlled virtual conditions. It also helps optimize material use, evaluate different mix designs, and predict structural performance without the need for extensive physical testing.

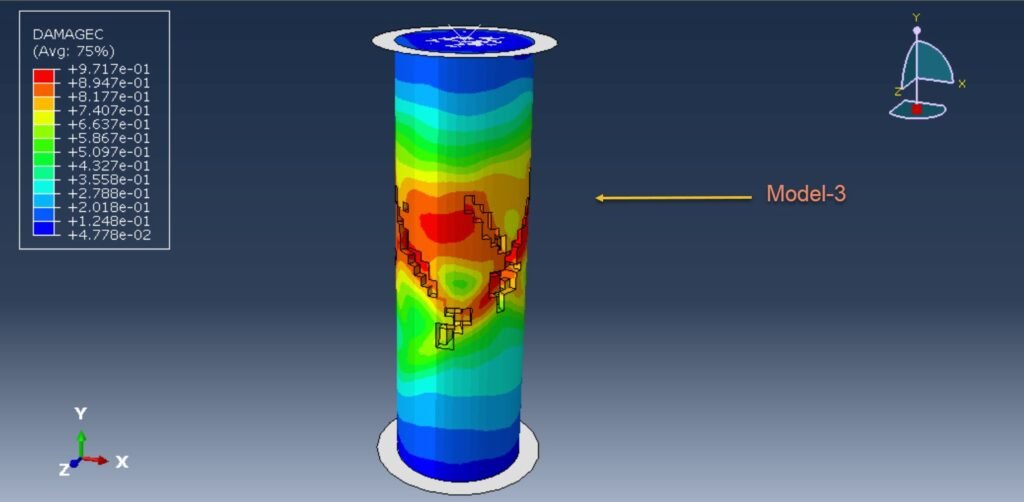

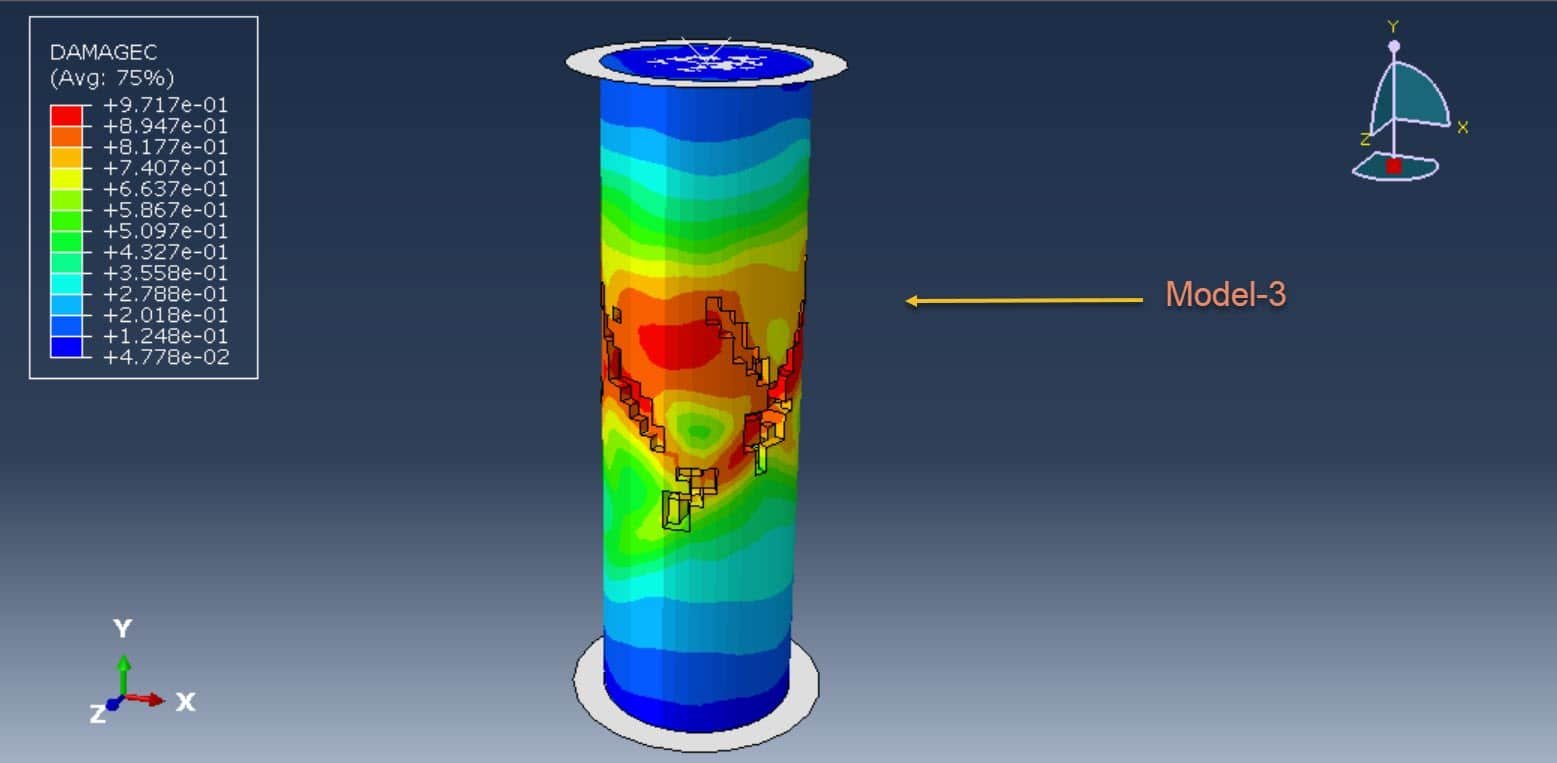

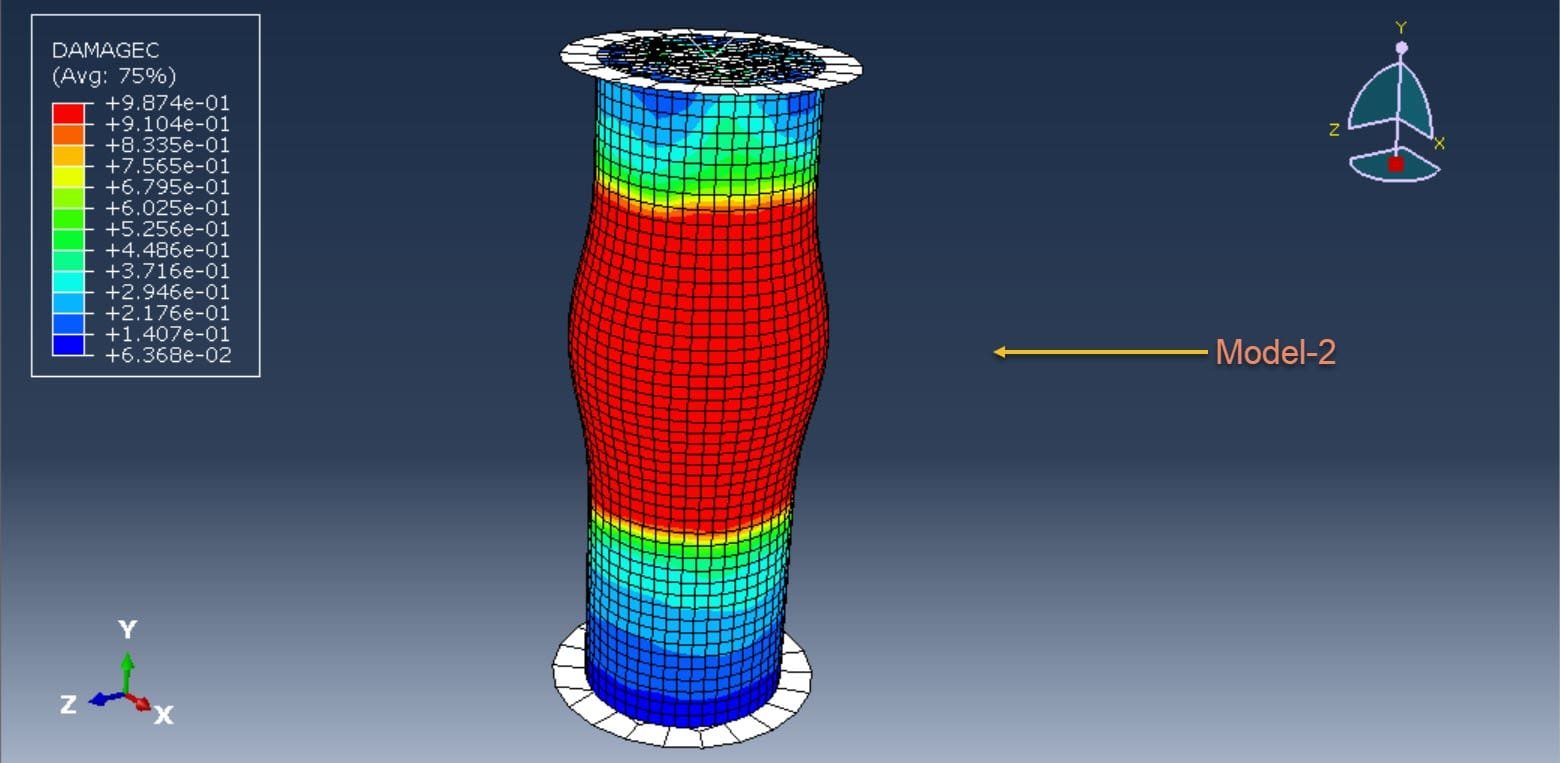

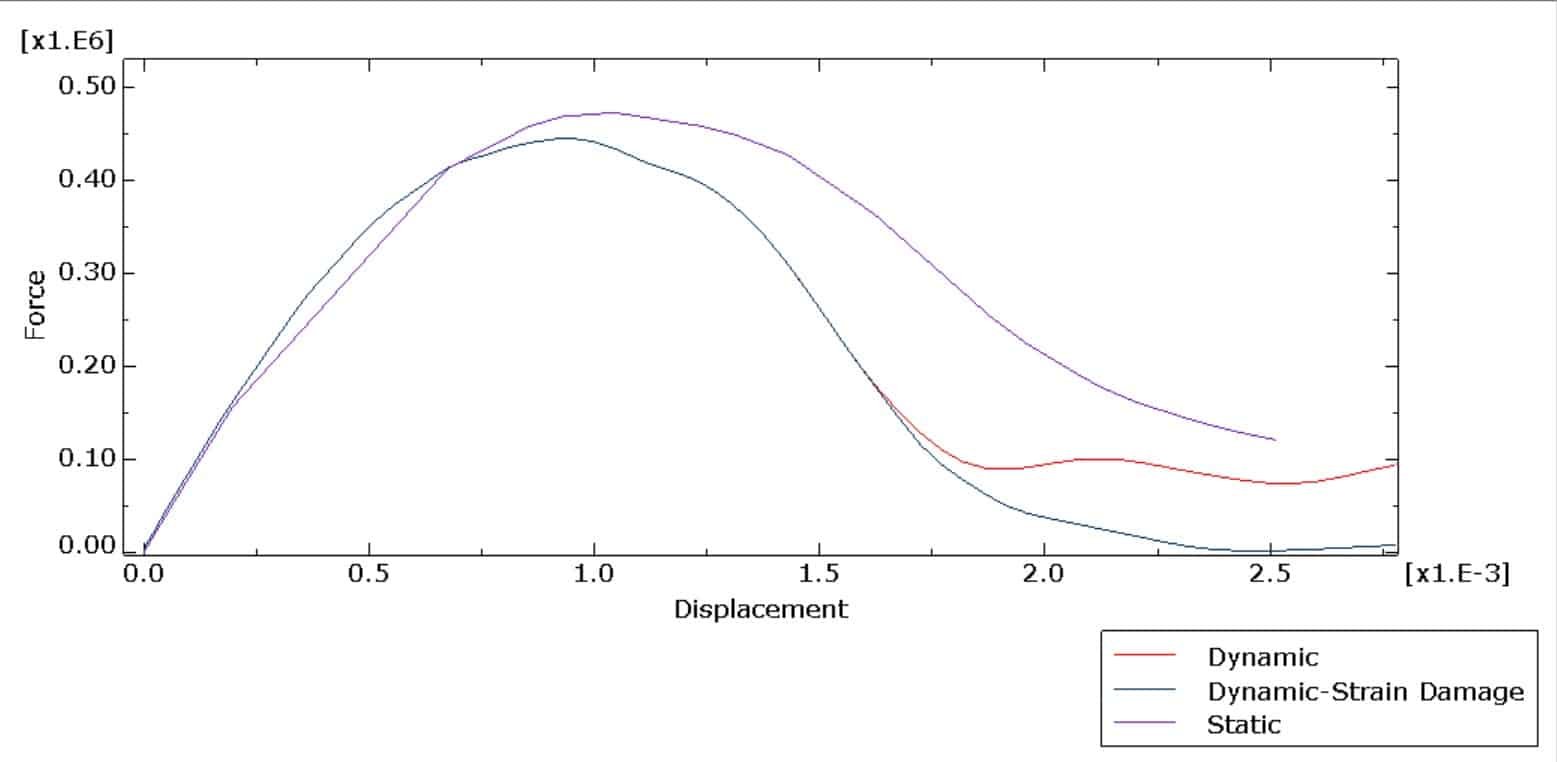

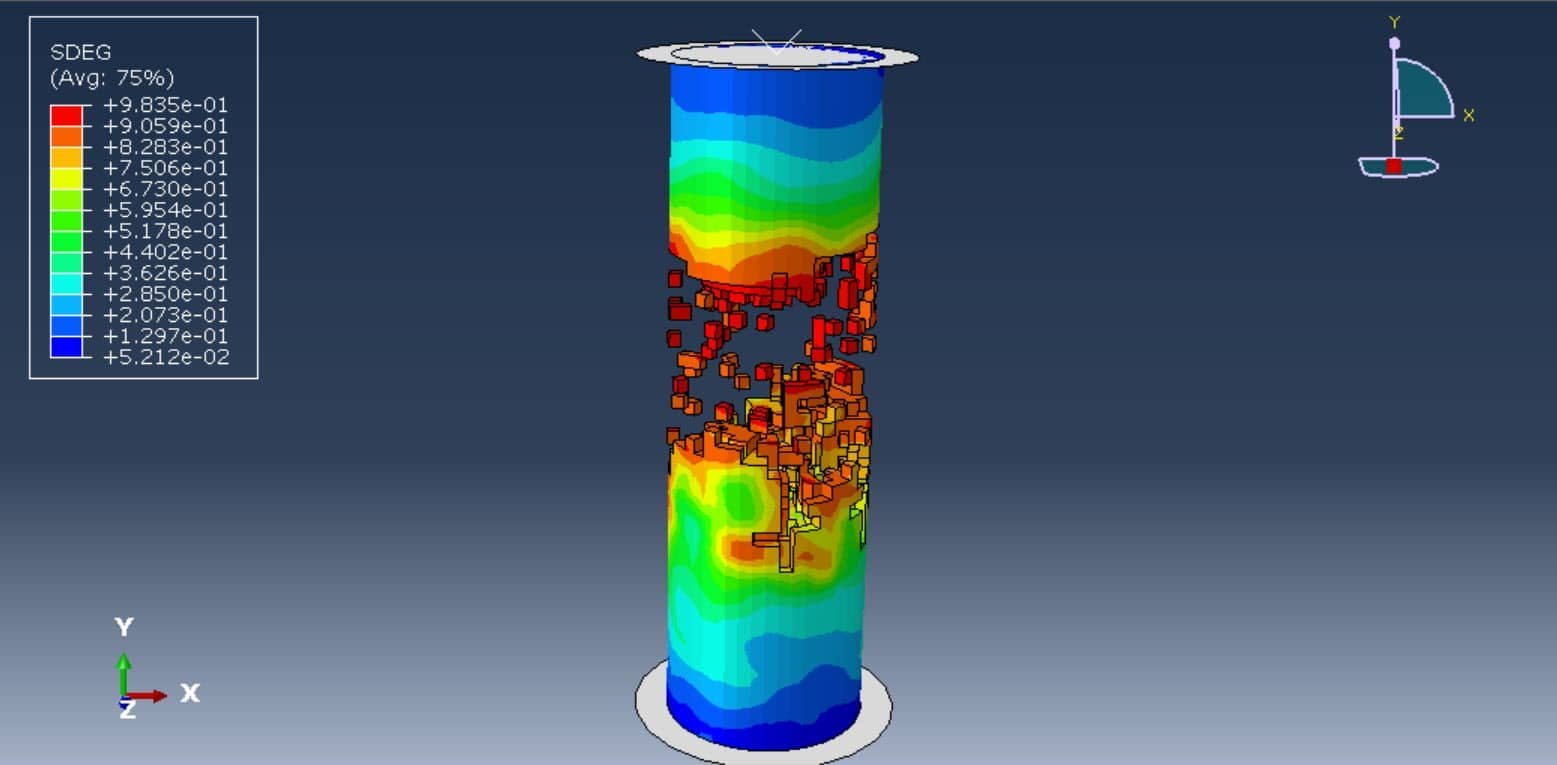

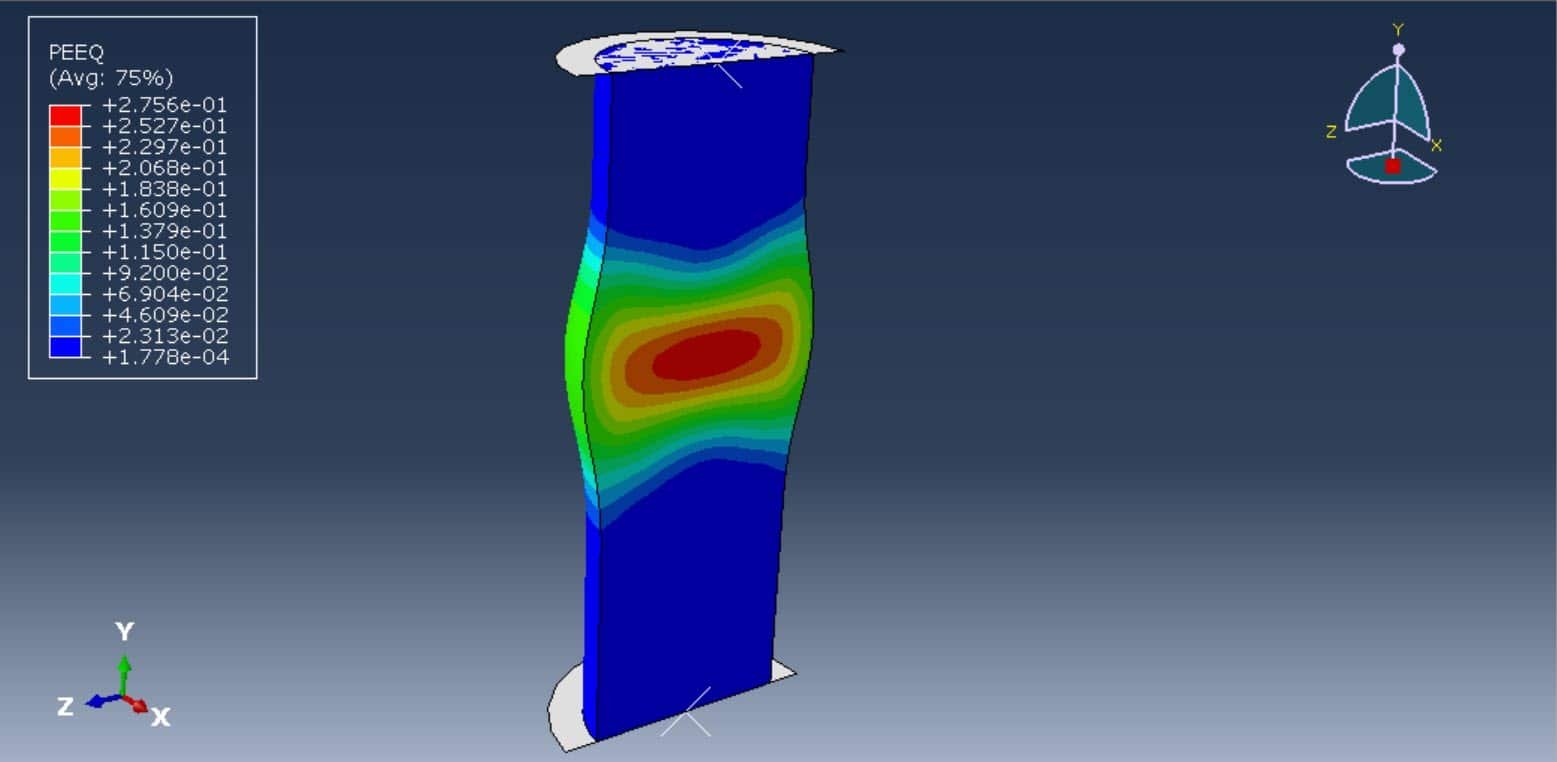

In this example, the aim of the simulation is compression among static, dynamic, and dynamic+ strain damage procedures to obtain the Force-Displacement diagram and maximum force capacity. To model concrete behavior under compression, the Concrete Damaged Plasticty is selected.

To predict the compressive strength of concrete based on material properties and geometry.

To visualize stress-strain behavior, including cracking and failure zones.

To validate material models (e.g., damage plasticity models for concrete).

To reduce experimental costs and time by minimizing the need for repeated physical tests.

Abaqus

€35,00 €30,00

Abaqus

€45,00 €30,00

Beam

€50,00 €30,00

Abaqus

€45,00 €29,00

See more

Want to receive push notifications for all major on-site activities?