Packages & Tutorials

Engineering Files & Tools

Software

Ready-to-use Models (FEA/CFD)

Excel Sheets & Hand Calculations

Introduction to Simulation of Aluminum-Bamboo Fiber-Aluminum Composite Pipe Under Internal Blast

Overview

The simulation of aluminum-bamboo fiber-aluminum composite pipes under internal blast loading is an emerging area of research in protective engineering and lightweight structural design. This sandwich composite structure combines the strength of aluminum with the energy-absorbing properties of natural bamboo fiber, creating a unique material system for blast mitigation applications.

Composite Structure

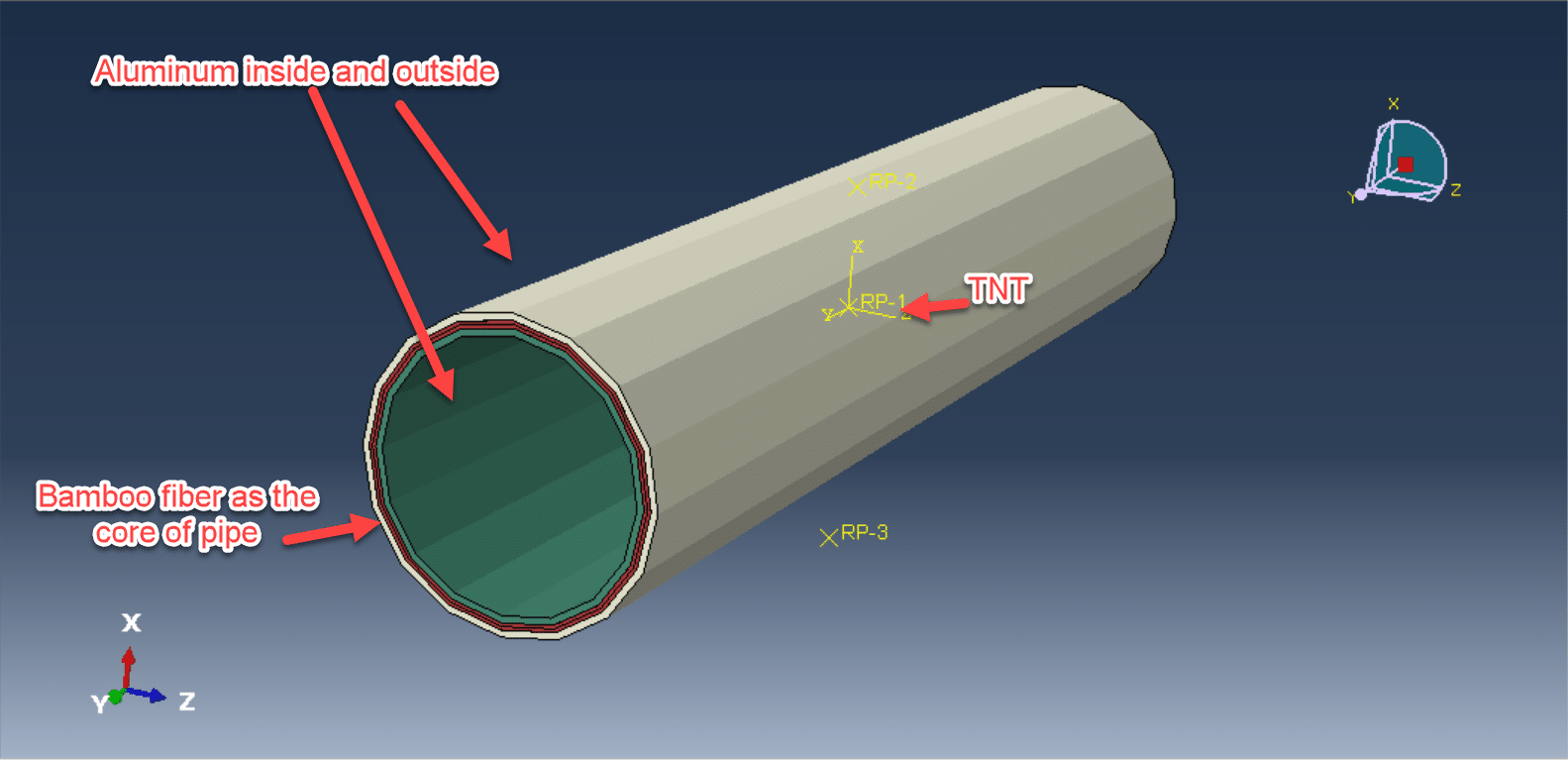

The pipe consists of three distinct layers:

1. Inner aluminum layer: Provides structural integrity and blast wave reflection

2. Bamboo fiber core: Acts as an energy-absorbing medium through fiber deformation and delamination

3. Outer aluminum layer: Offers additional structural support and fragment protection

Simulation Challenges

Modeling this composite under blast conditions involves several complexities:

Anisotropic behavior of bamboo fiber reinforcement

Interface bonding characteristics between metal and natural fiber layers

Strain-rate dependent material properties

Progressive damage mechanisms in both metallic and fiber components

Fluid-structure interaction during blast wave propagation

Applications

Potential applications for this simulated analysis include:

Lightweight protective structures for military and civilian use

Blast-resistant piping in industrial facilities

Energy-absorbing components in transportation systems

Sustainable alternatives to conventional blast mitigation materials

Simulation Approaches

Common methodologies include:

1. Finite Element Analysis (FEA) with explicit dynamics solvers

2. Coupled Eulerian-Lagrangian techniques for blast modeling

3. Multi-scale modeling approaches for composite behavior

4. Damage progression algorithms for interface failure

The simulation of this novel composite provides valuable insights into its blast-resistant capabilities while supporting the development of more sustainable protective materials.

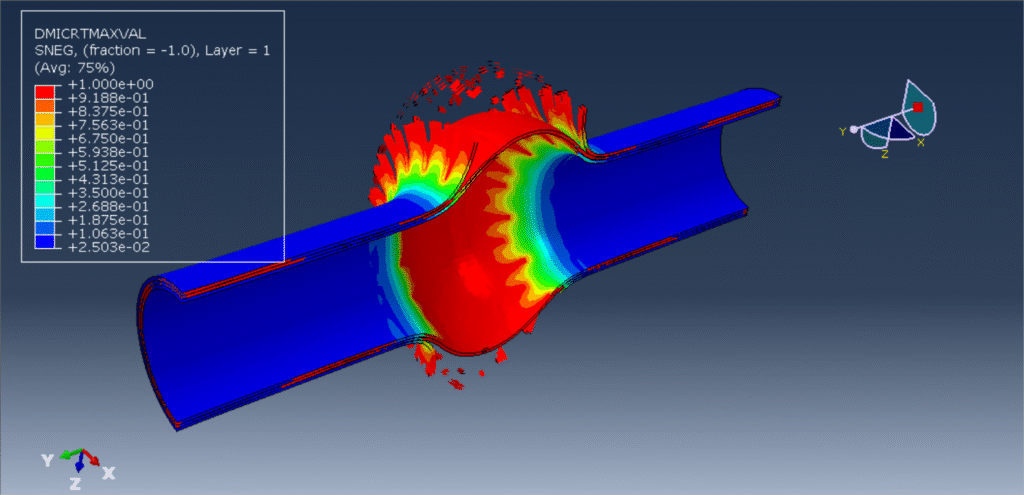

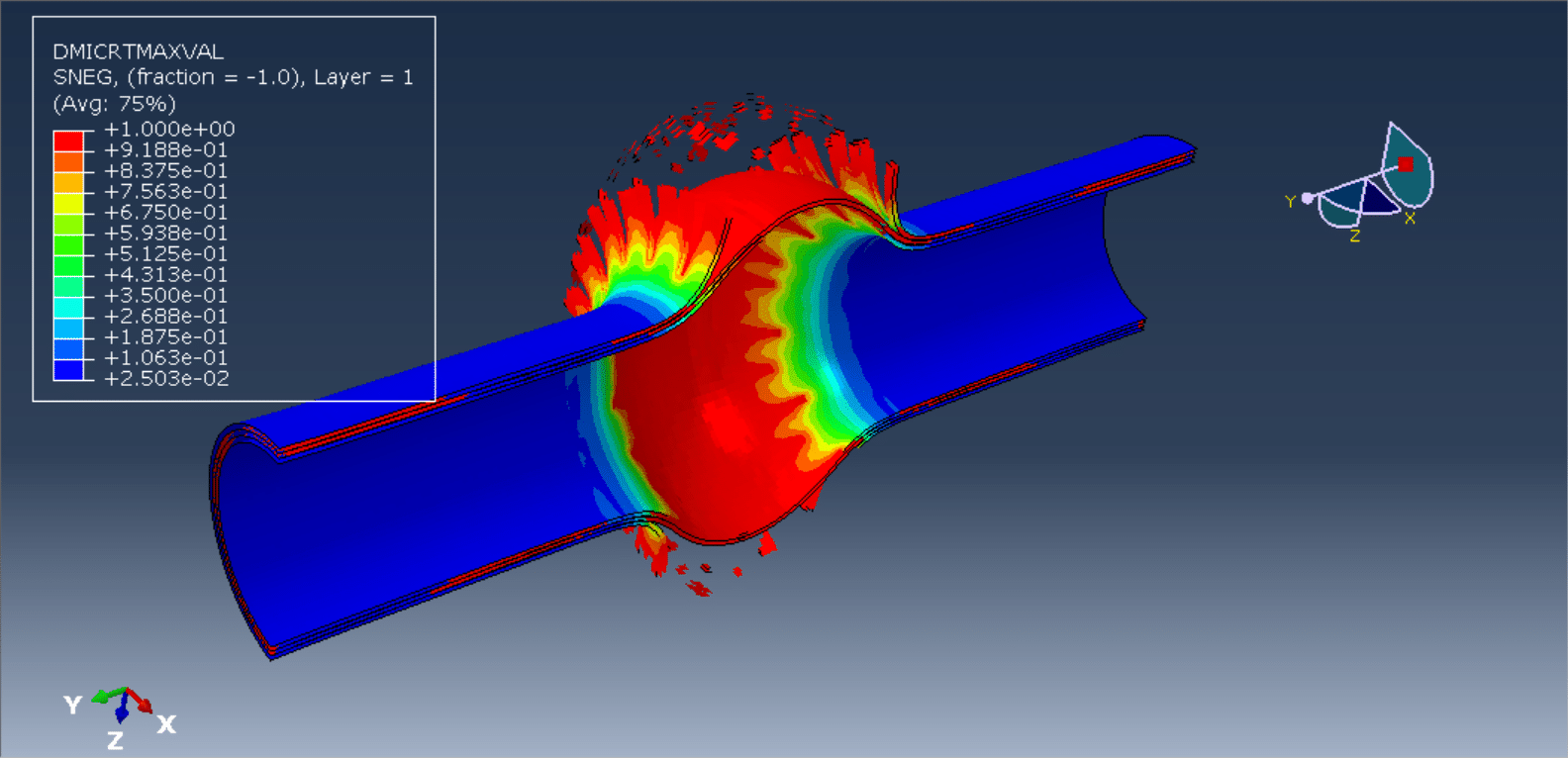

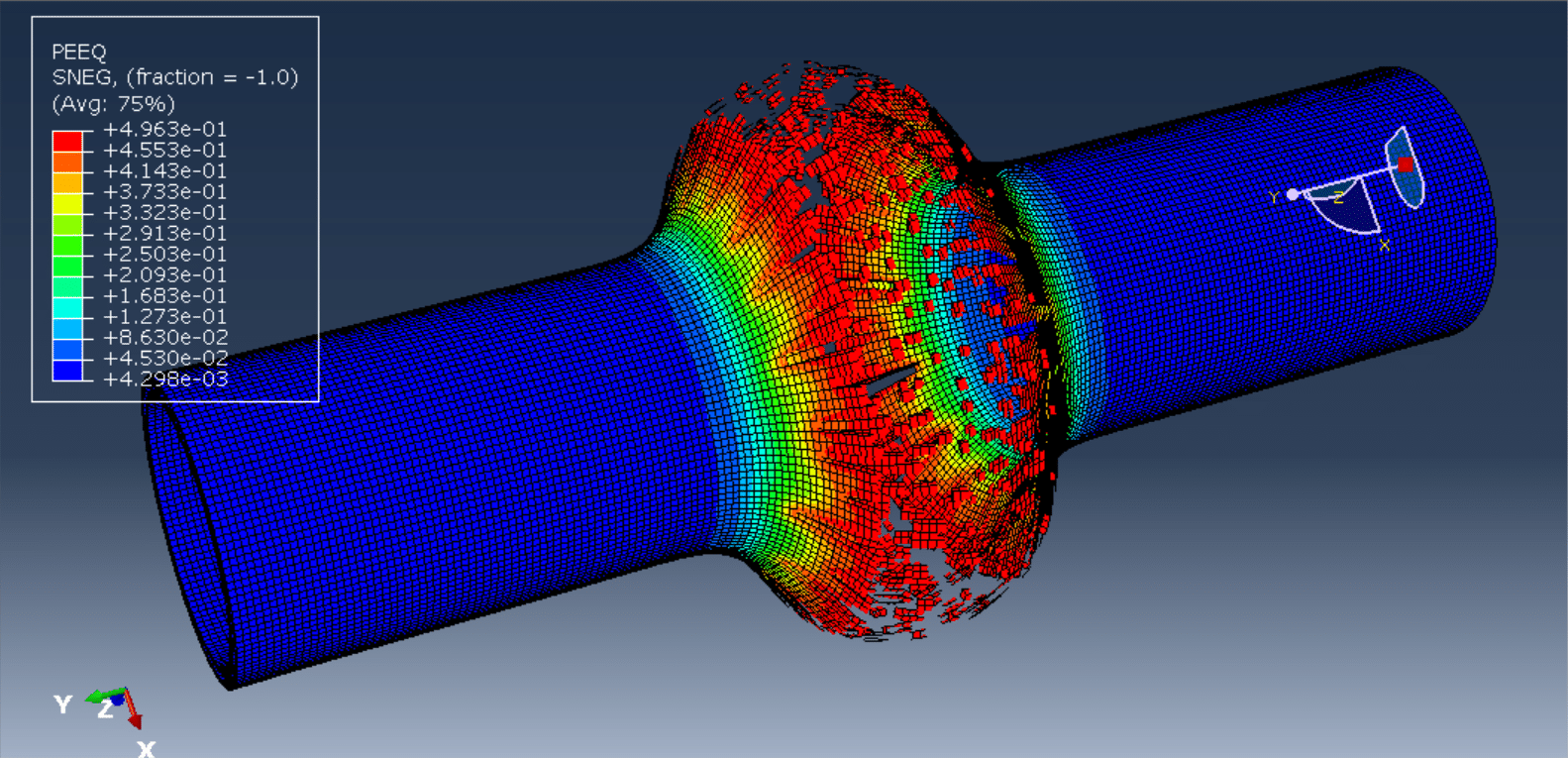

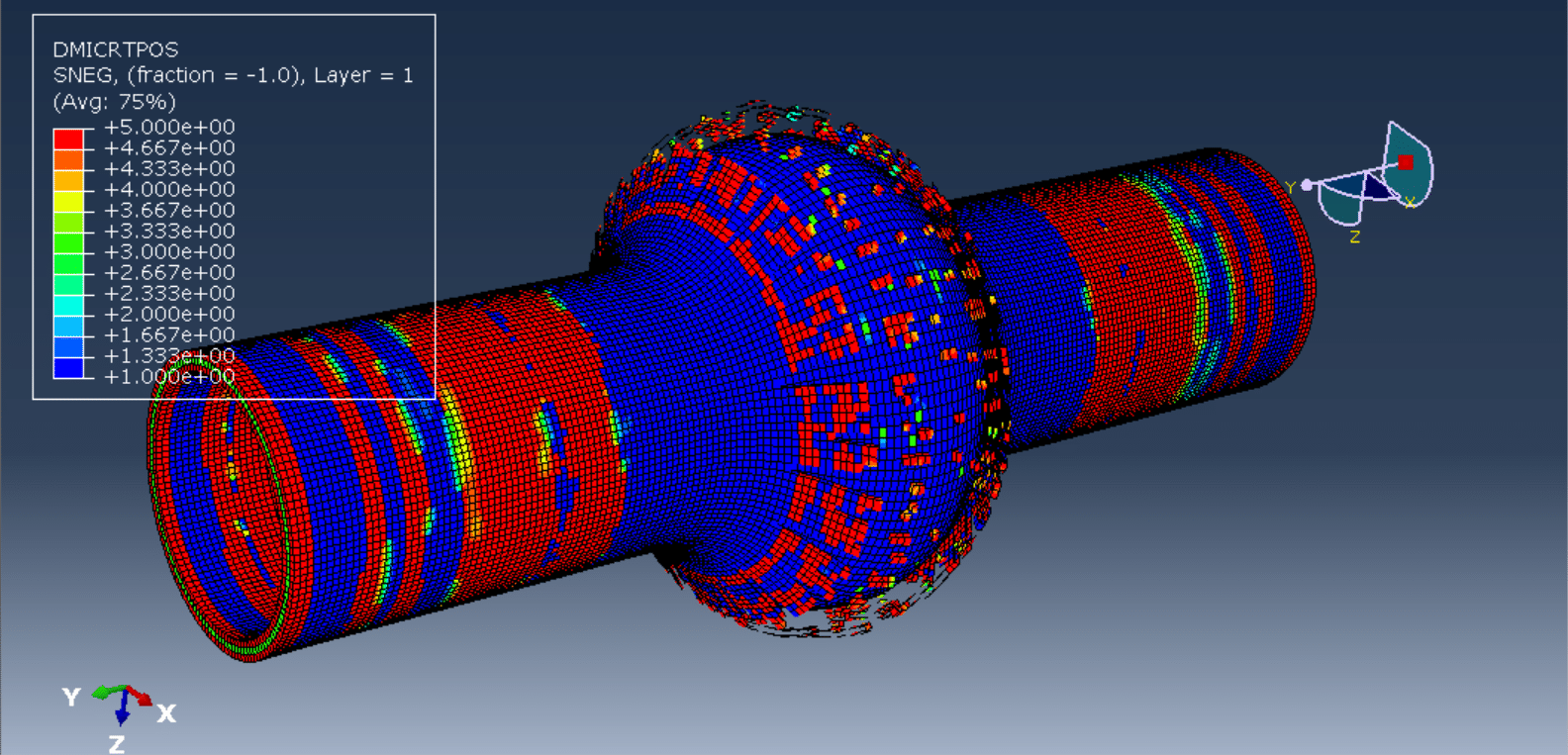

In this tutorial, the Simulation composite Pipe(Aluminum-Bamboo fiber-Aluminum) under internal blast in Abaqus has been investigated. All three pipes are modeled as shell parts. The configuration of a composite pipe, which combines the advantages of joining two thin, stiff, and strong skins to a thick and low-density core, results in superior crushing characteristics and impact or blast resistance under out-of-plane loading when compared to single solid components. In this context, bamboo, a very abundant natural resource in tropical regions, has been exploited as a core material in composite pipes.

The Hashin damage model is considered for the bamboo fiber pipe. Damage initiation refers to the onset of degradation at a material point. In Abaqus, the damage initiation criteria for fiber-reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression. The dynamic explicit step, cohesive interaction between the pipes, proper boundary conditions, and meshes are selected for all parts. After the simulation, all results such as stress, strain, damage, failure, bamboo damage, and others are available.

Dynamic

€1,00 €0,00

See more

Want to receive push notifications for all major on-site activities?