Product Overview:

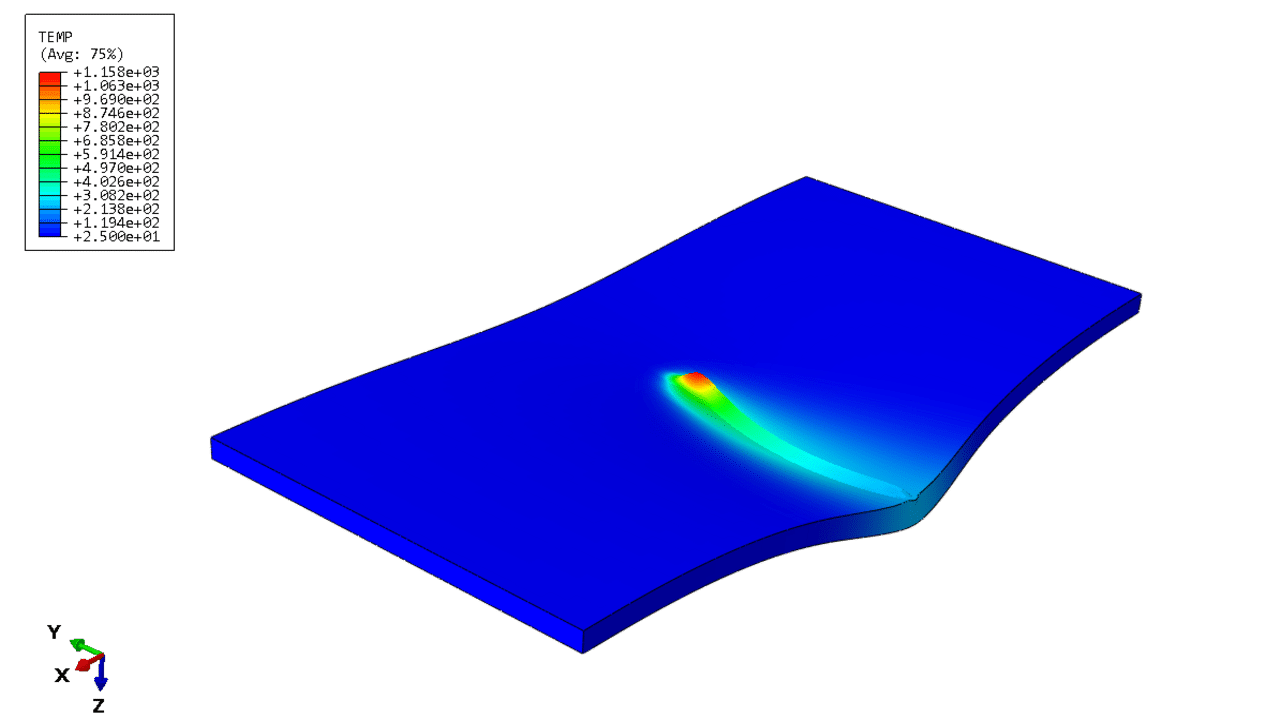

This video presents a comprehensive, step-by-step tutorial on simulating the welding process with the DFLUX subroutine to analyze non-uniform heat distribution. For this example, we designed a geometric model and defined temperature-dependent material properties. We utilized steel as the base material, incorporating characteristics such as elasticity, plasticity, thermal conductivity, expansion, and specific heat that vary with temperature. The applied heat source generates significant thermal stresses within the plate.

Key Topics:

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?