Product Overview:

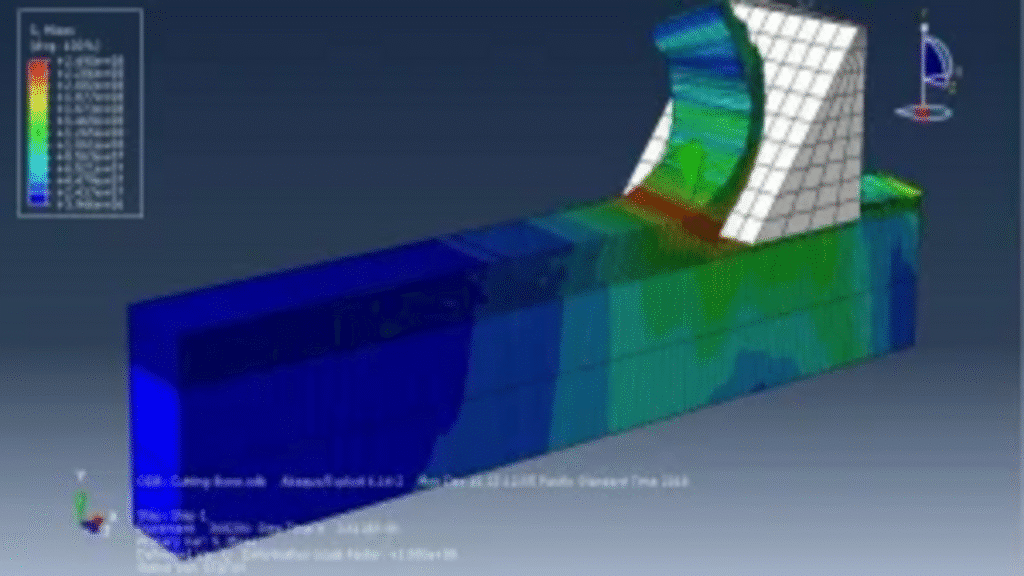

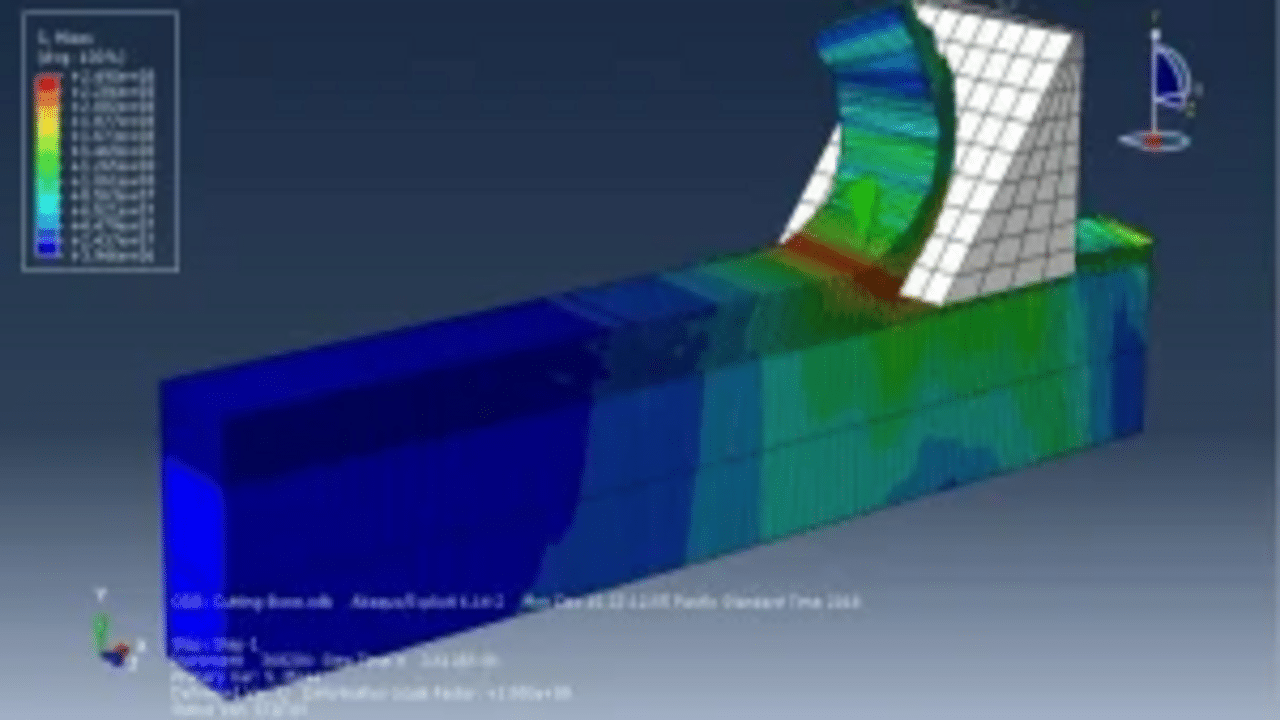

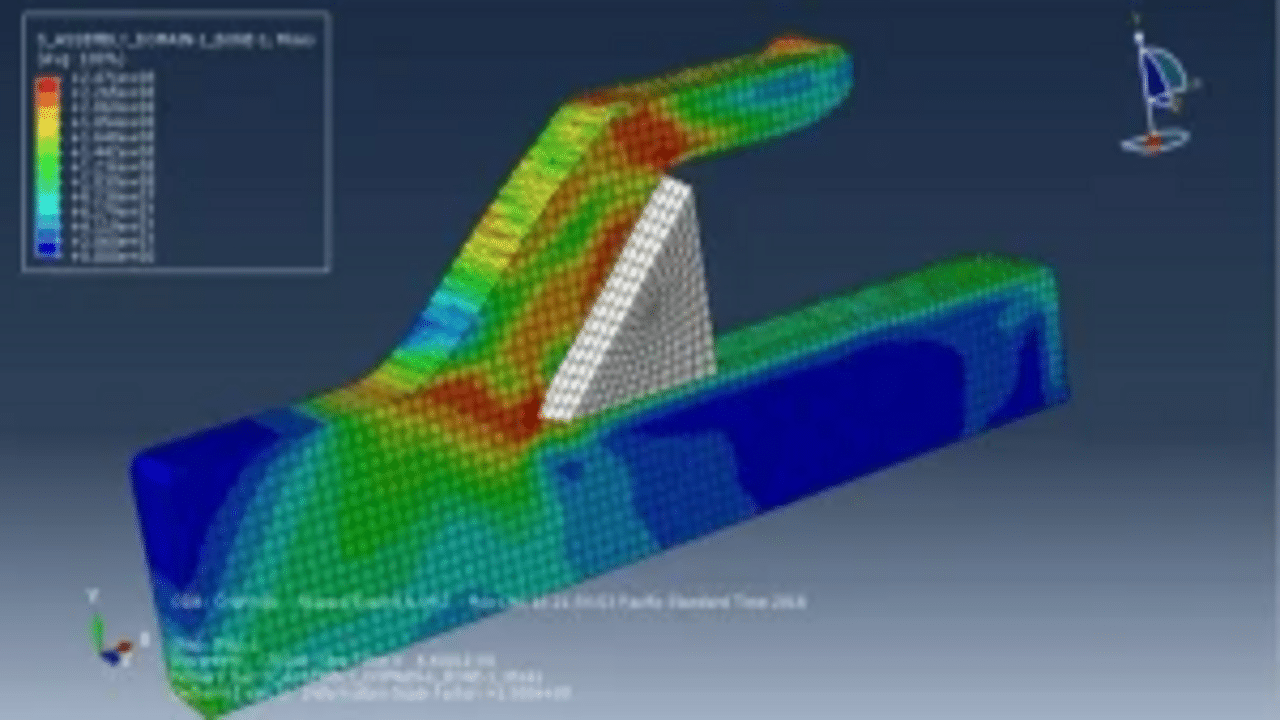

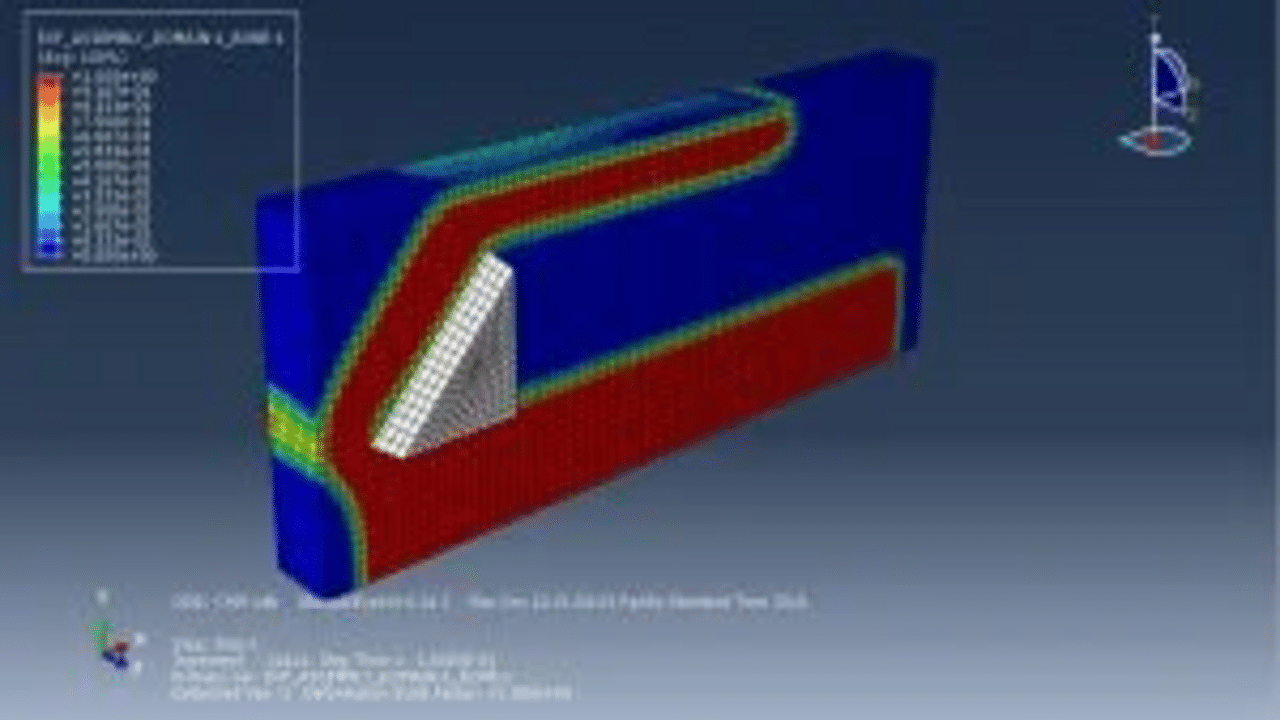

Cutting procedures on bone are frequently performed in orthopedic trauma surgery and dentistry. These operations encompass various techniques, such as grinding, sawing, and drilling. In manufacturing, the precision of machining operations is crucial for optimizing both efficiency—encompassing time and costs—and surface integrity. This principle is equally relevant in bone cutting, where there is a need to balance reduced cutting time (to minimize overall surgical duration) with high surface quality. Poor surface quality can lead to thermal damage in the bone, resulting in complications like osteonecrosis.

Validating modeling tools such as the finite element method (FEM) is essential for analyzing and defining bone machining processes. A key aspect of achieving accurate simulations involves correctly establishing constitutive equations that reflect the mechanical behavior of bone tissue. For this simulation, an Eulerian approach has been implemented, utilizing the Johnson-Cook material model to represent bone properties. The dynamic temperature explicit step is deemed suitable for this type of analysis.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?