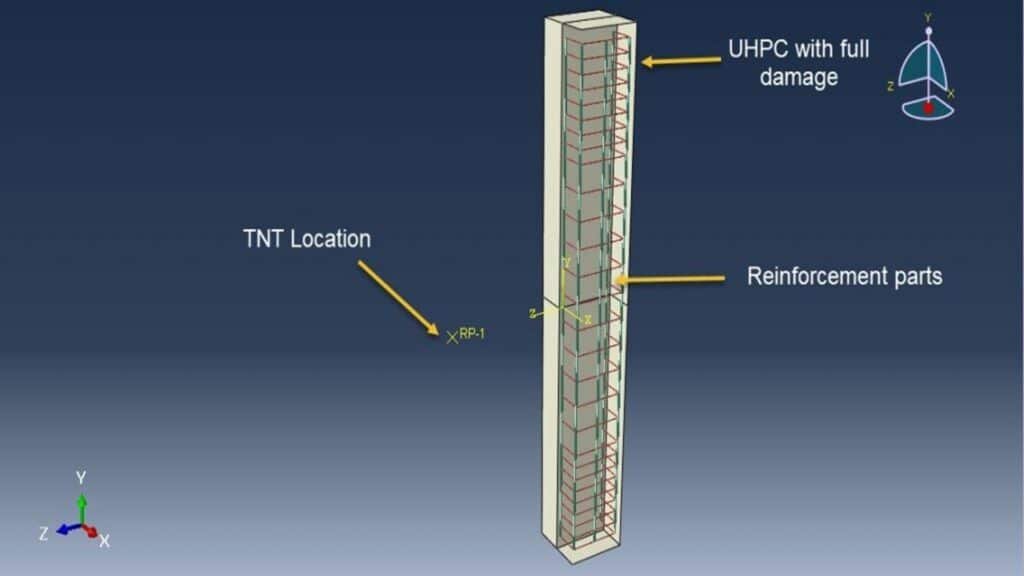

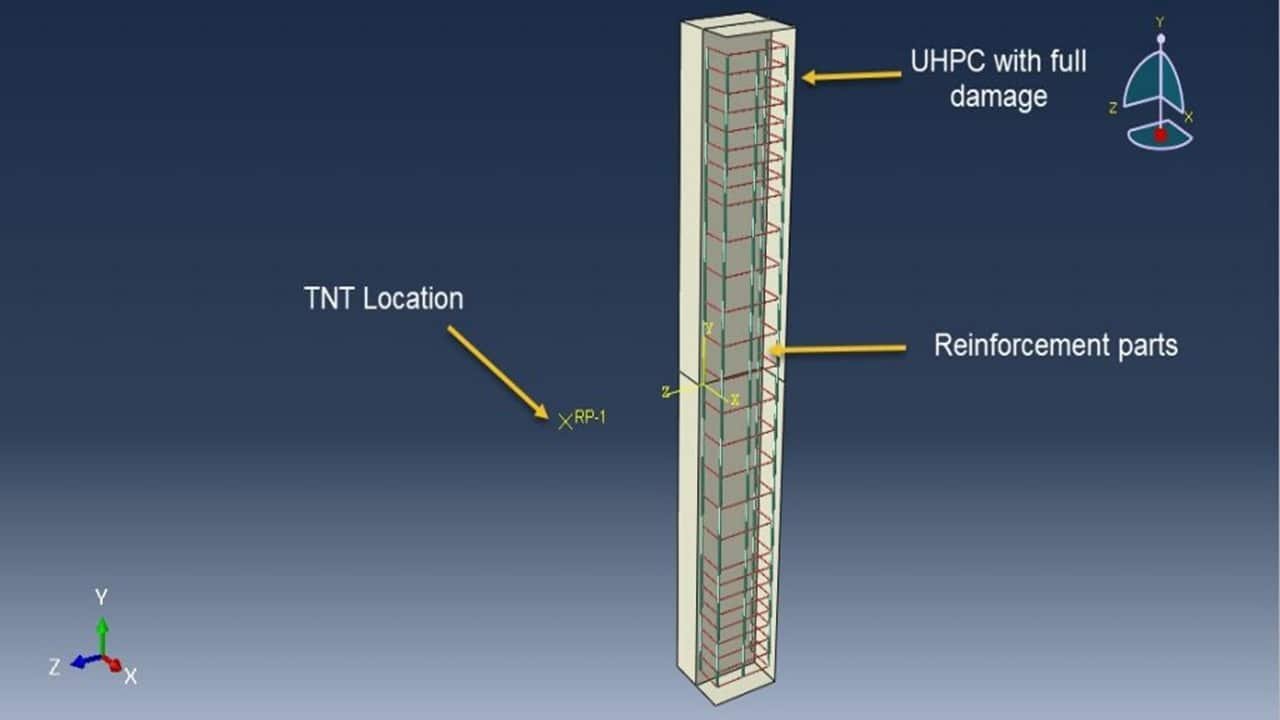

This tutorial focuses on the simulation of an air blast explosion impacting a reinforced Ultra-High-Performance Concrete (UHPC) column, with a detailed analysis of the resulting damage.

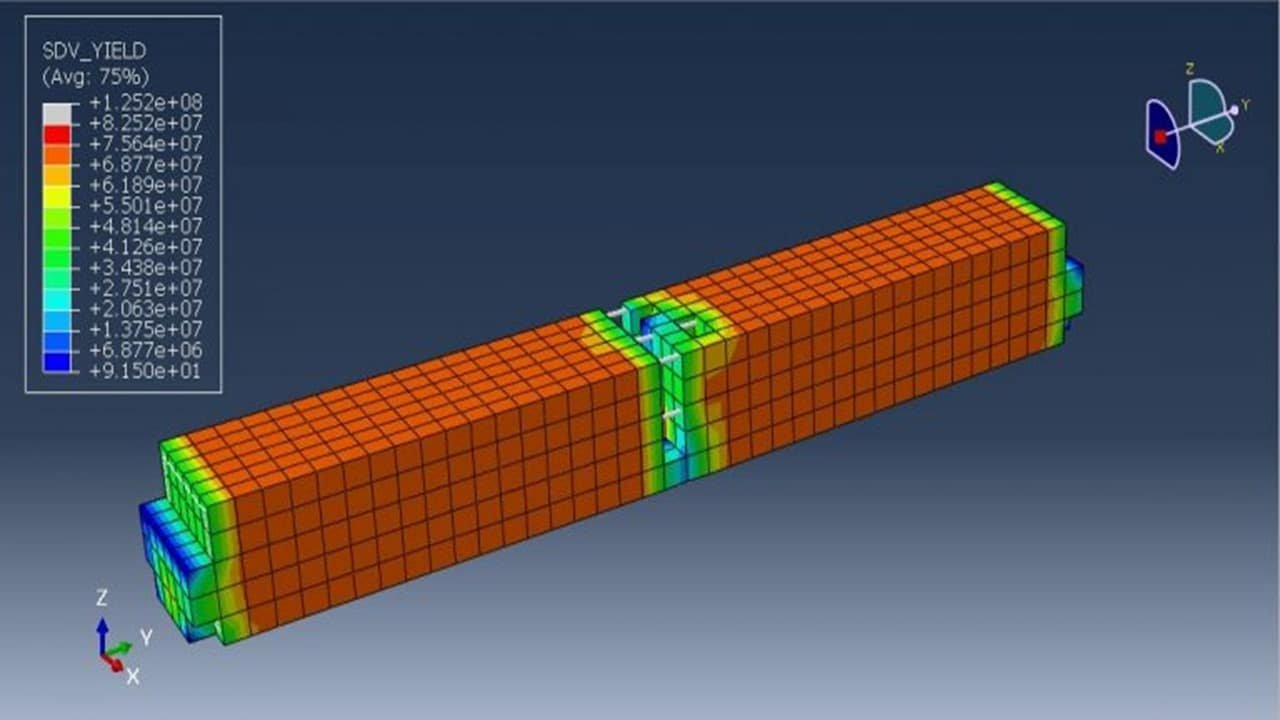

The UHPC is modeled as a three-dimensional solid part, while the embedded steel reinforcement bars and strips are represented using three-dimensional wire elements. To simulate concrete behavior, the Concrete Damaged Plasticity Model (CDPM) is employed, capturing the two primary failure mechanisms: tensile cracking and compressive crushing. The CDPM is driven by stress-strain data in both tension and compression, based on the concrete’s tested compressive strength.

However, it is important to note that CDPM is not well-suited for modeling concrete under high-intensity blast loads. For more accurate response under such extreme conditions, an advanced material model should be used—either provided through input files as code definitions or implemented via a VUMAT subroutine.

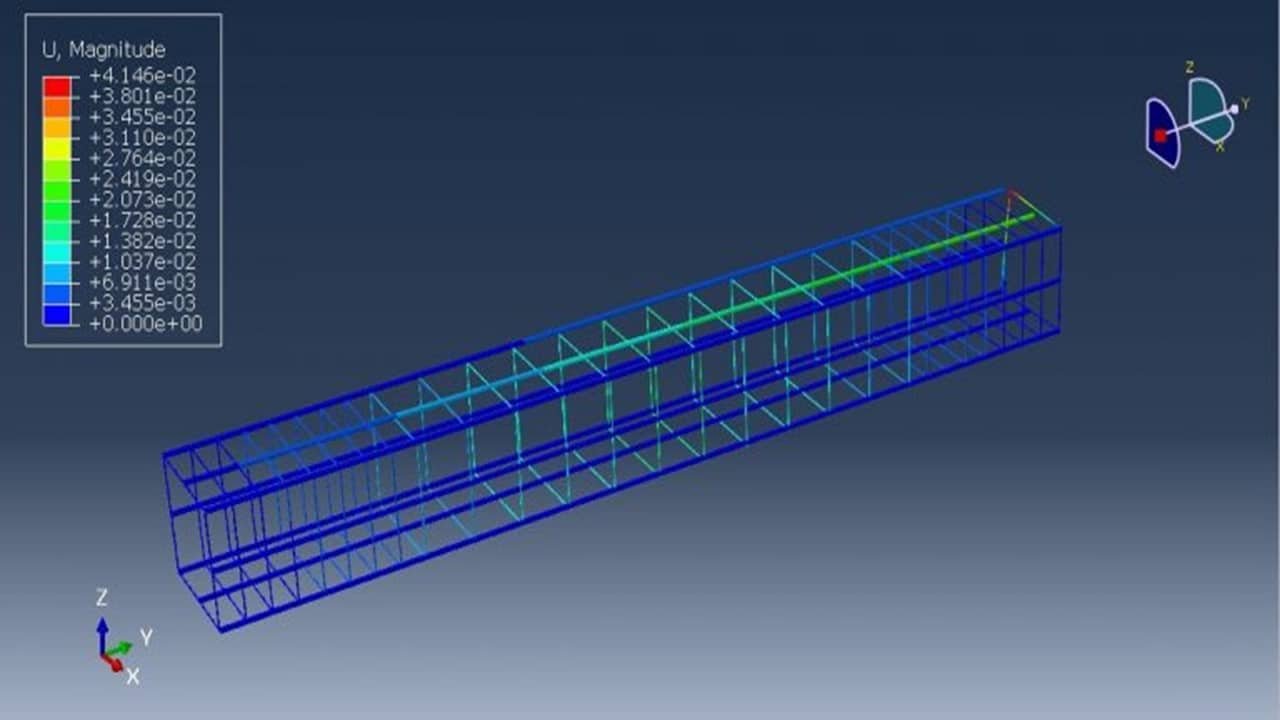

Steel reinforcement is modeled with elastic-plastic material behavior. A dynamic explicit step is used for the analysis to capture the high strain-rate effects typical of blast loading. The steel bars are embedded within the UHPC column, which is constrained by fixed boundary conditions at both ends.

To simulate the blast load, the CONWEP method is applied. A sufficiently refined mesh is essential to ensure accurate results.

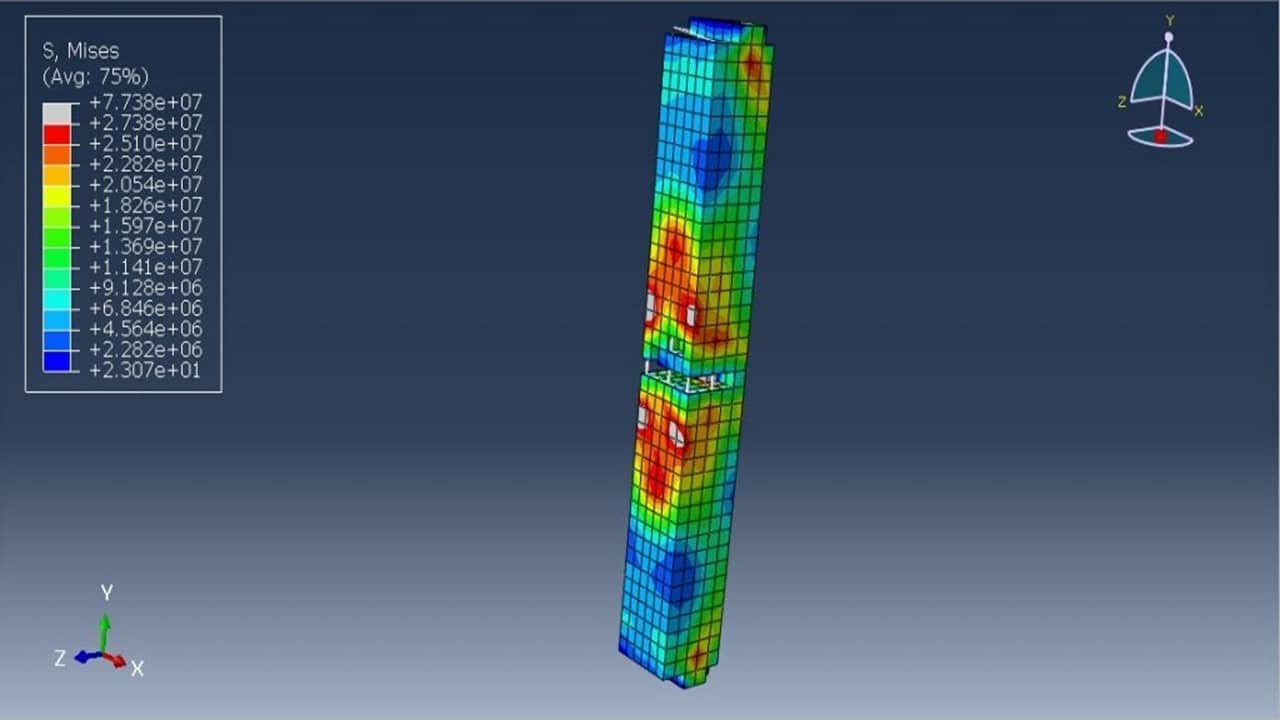

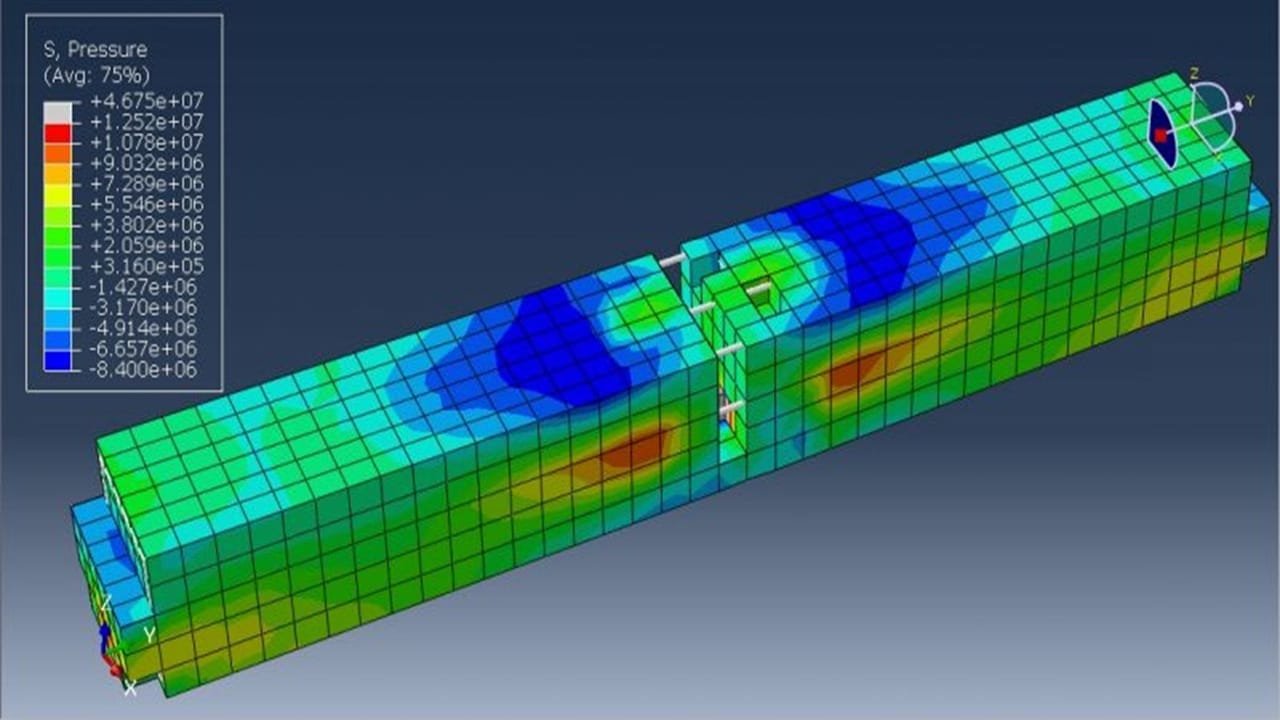

Post-simulation, a range of output results is available for analysis, including stress, strain, failure patterns, and material damage indicators.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?