Product Overview:

In recent years, substantial research has focused on modeling impact dynamics. For low-speed impacts, such as in the shot peening metalworking process, semi-analytical methods are typically employed to model both thick (assuming a half-space) and thin (finite-depth) structures. However, for higher-speed impacts, such as those occurring in the cold spray particle deposition process, explicit finite element analysis codes like ABAQUS and LS-DYNA have been utilized to investigate the complete deformation history of the materials involved.

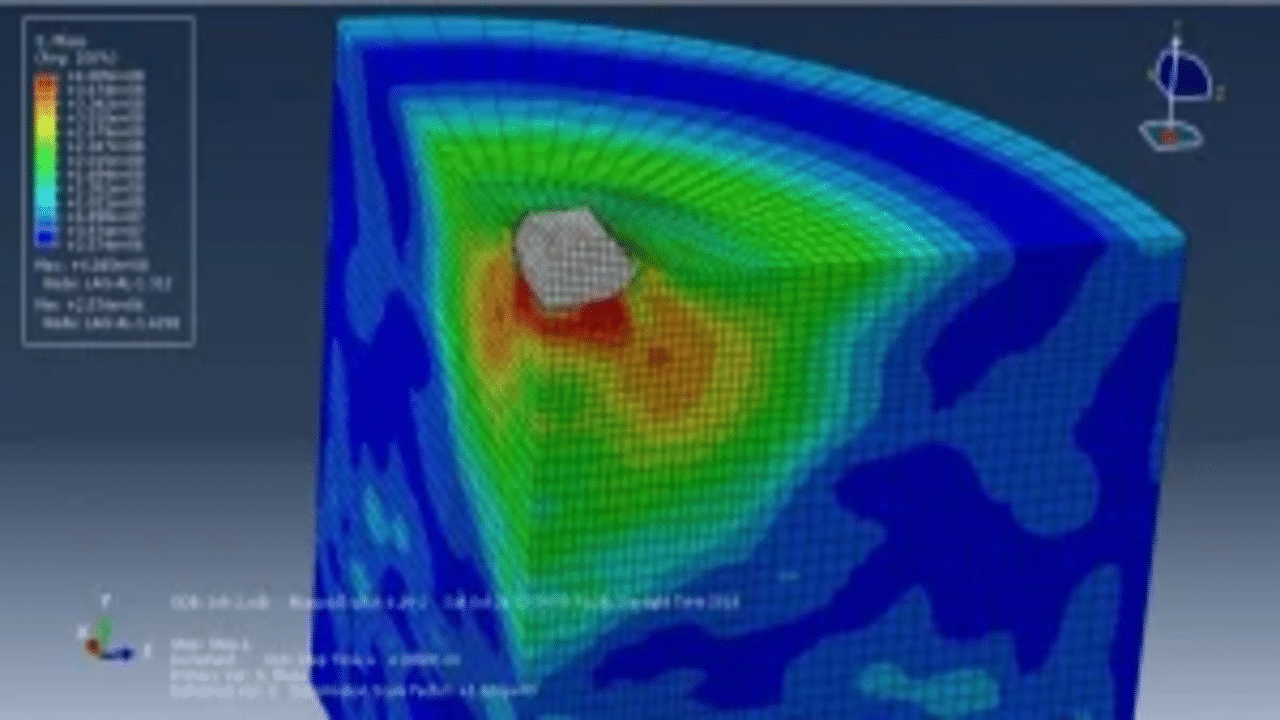

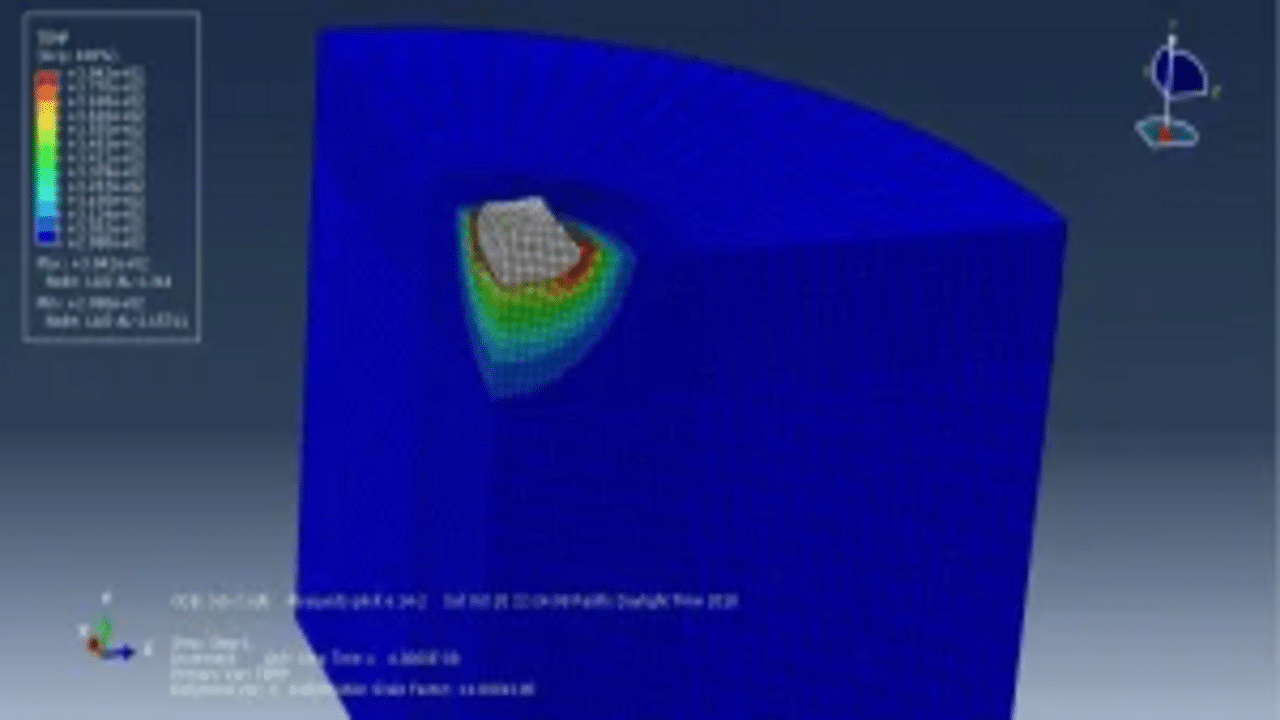

Cold gas dynamic spray, or simply “cold spray,” was initially developed in the mid-1980s. In this process, spray particles (ranging from 1 to 50 micrometers in size) are accelerated to high velocities (300 to 1200 m/s) by a high-speed gas flow. This leads to the formation of dense, high-quality coatings due to the plastic deformation of particles upon impact with the solid surface of the substrate. Given the transient nonlinear dynamics and contact phenomena involved, the interactions between the particles and the substrate during cold spray deposition are challenging to analyze experimentally. Traditional microstructural and microanalytical studies often provide limited insight into the various bonding mechanisms at play. Consequently, numerical simulation of particle/substrate interactions has become crucial for understanding the cold spray bonding mechanisms.

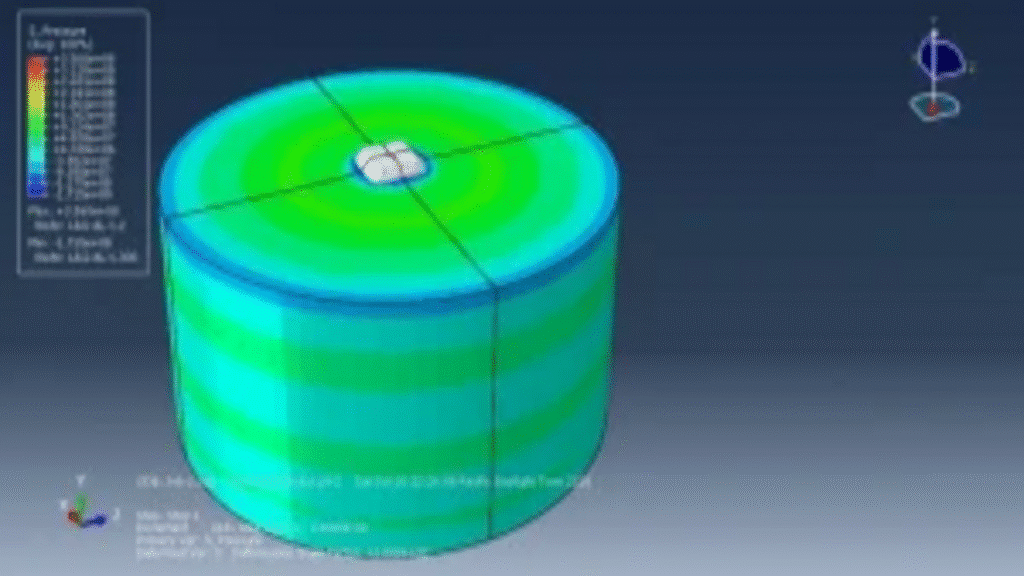

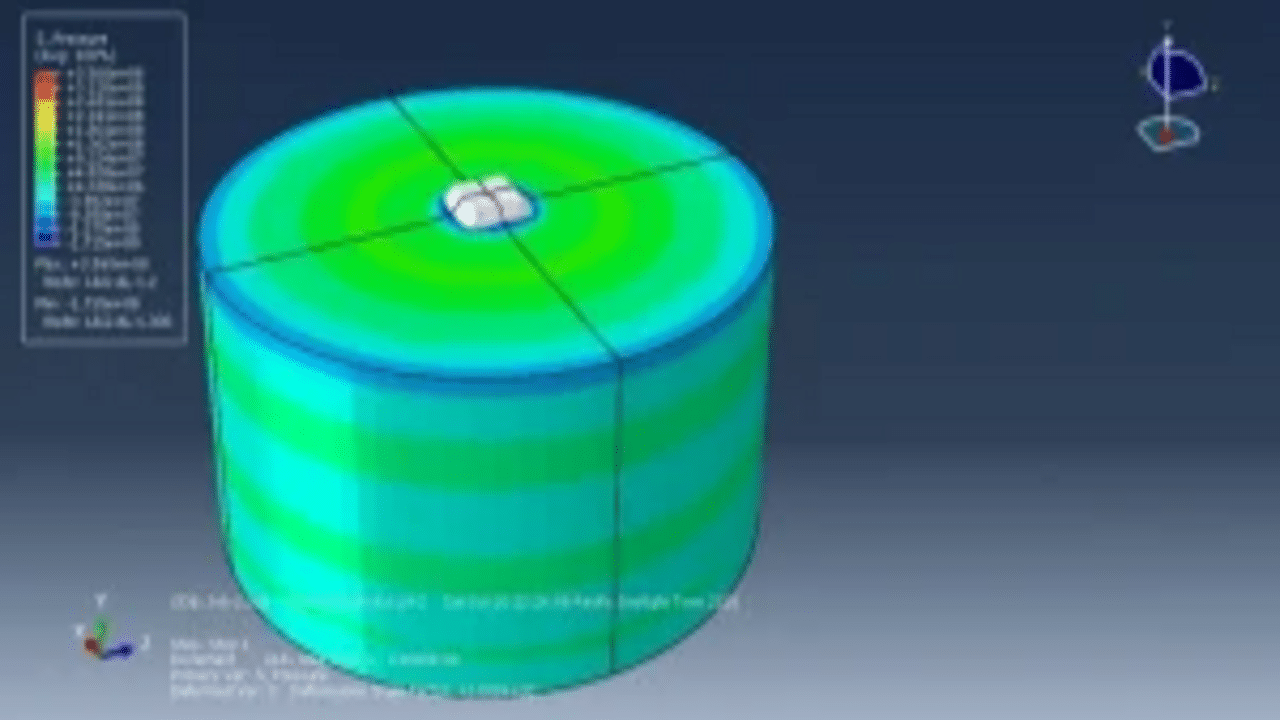

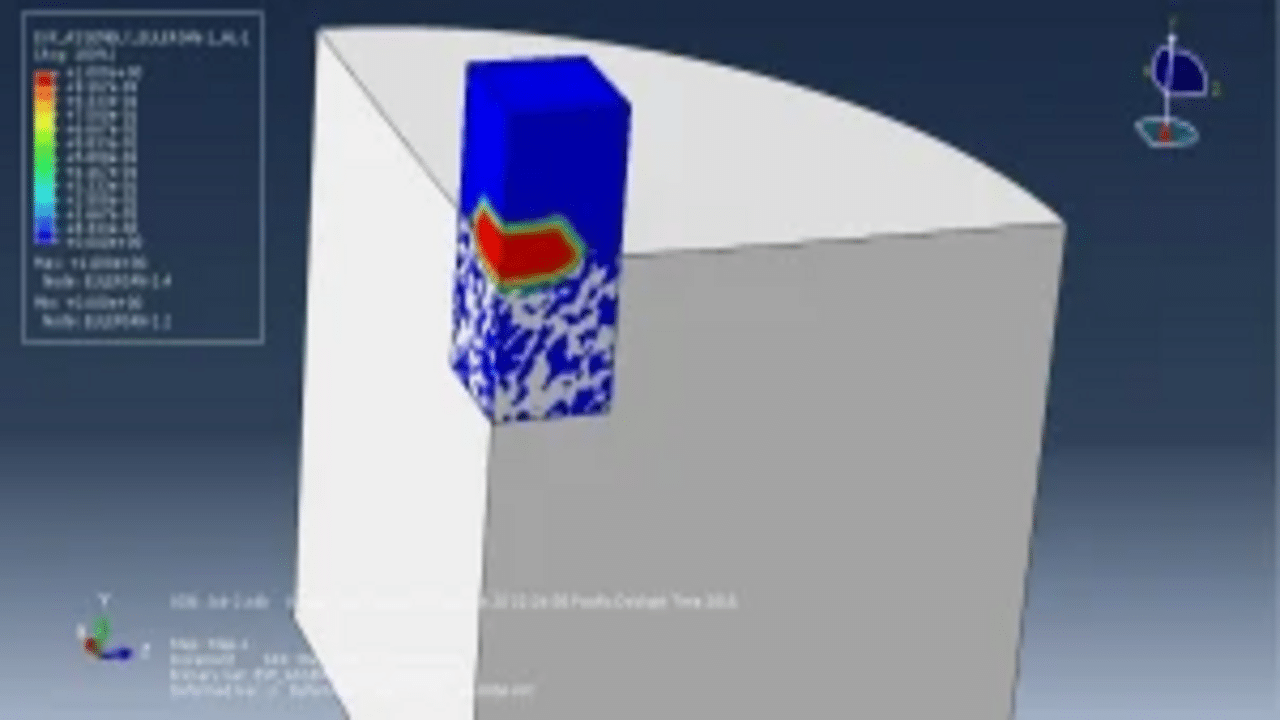

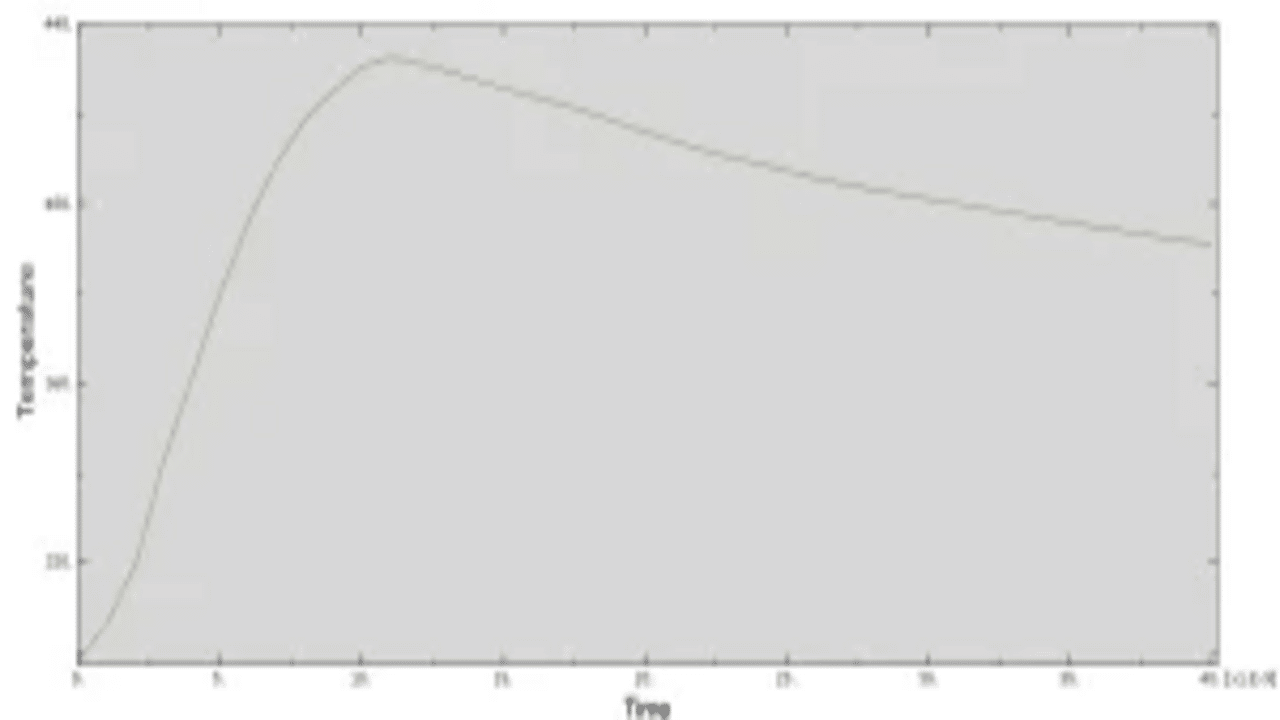

In this simulation, a three-dimensional Coupled Eulerian-Lagrangian (CEL) analysis is performed. Aluminum is selected for both the target and the spray particles, and the Johnson-Cook material model is utilized to accurately capture the material behavior. The dynamic temperature explicit formulation is deemed suitable for this type of analysis.

Let’s Learn and Collaborate

Get VIP access to new content.

Sign up for weekly deals and news.

Engineering Downloads is a hub for learning,

collaboration, and sharing engineering models

and resources.

© 2025 Engineering Downloads. All rights reserved.

Want to receive push notifications for all major on-site activities?