Papers abstract:

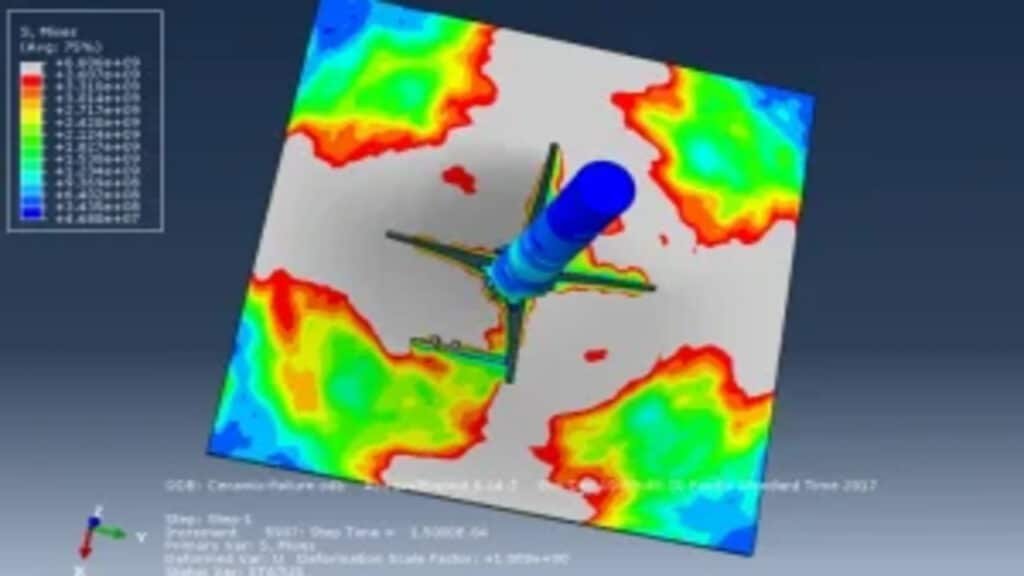

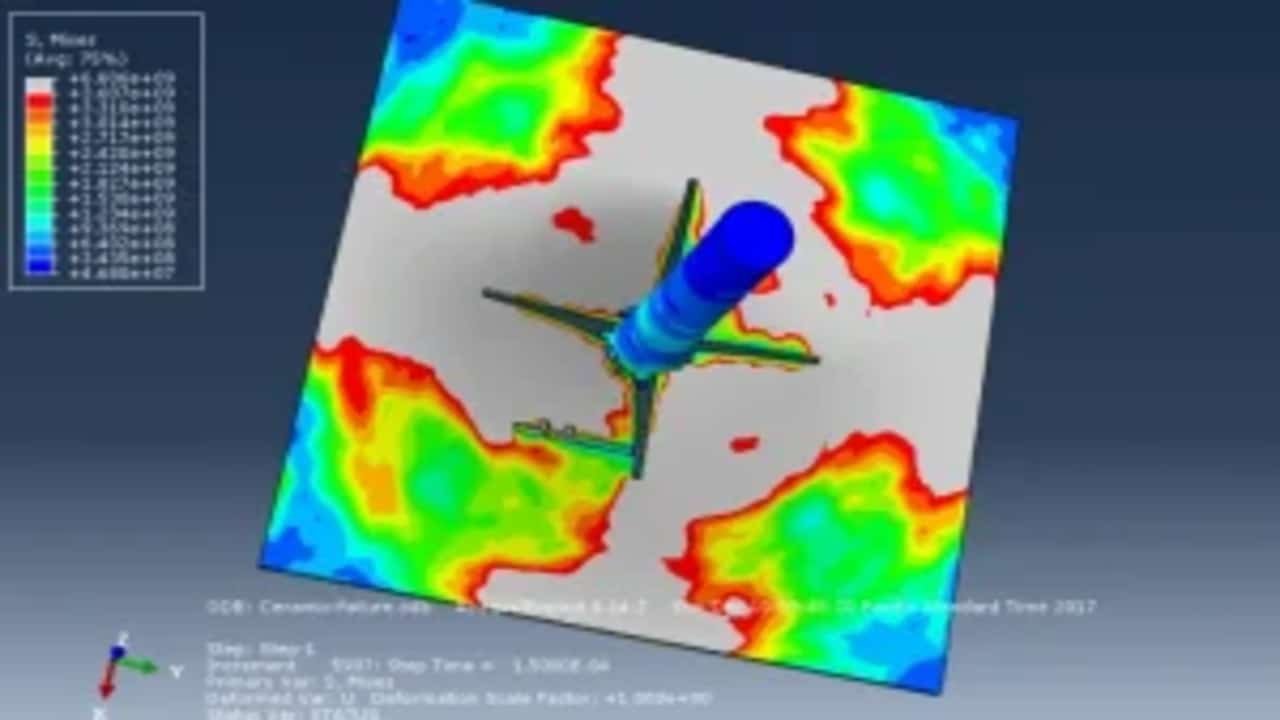

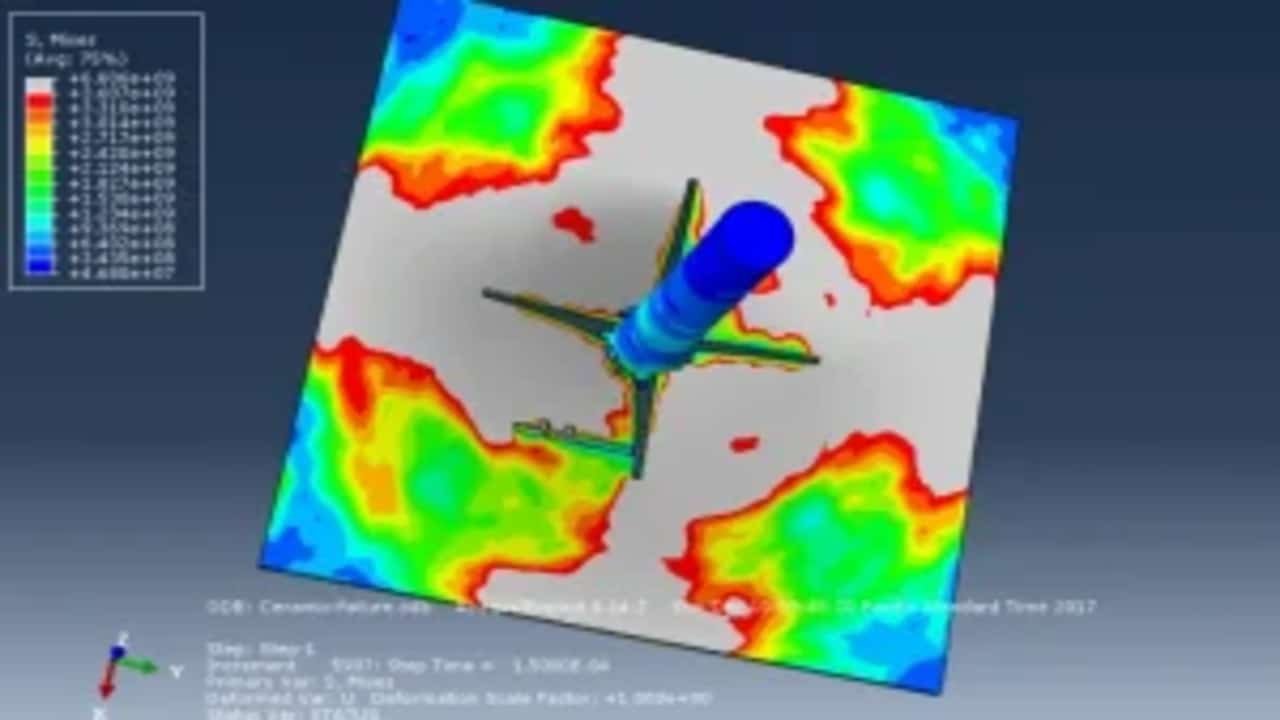

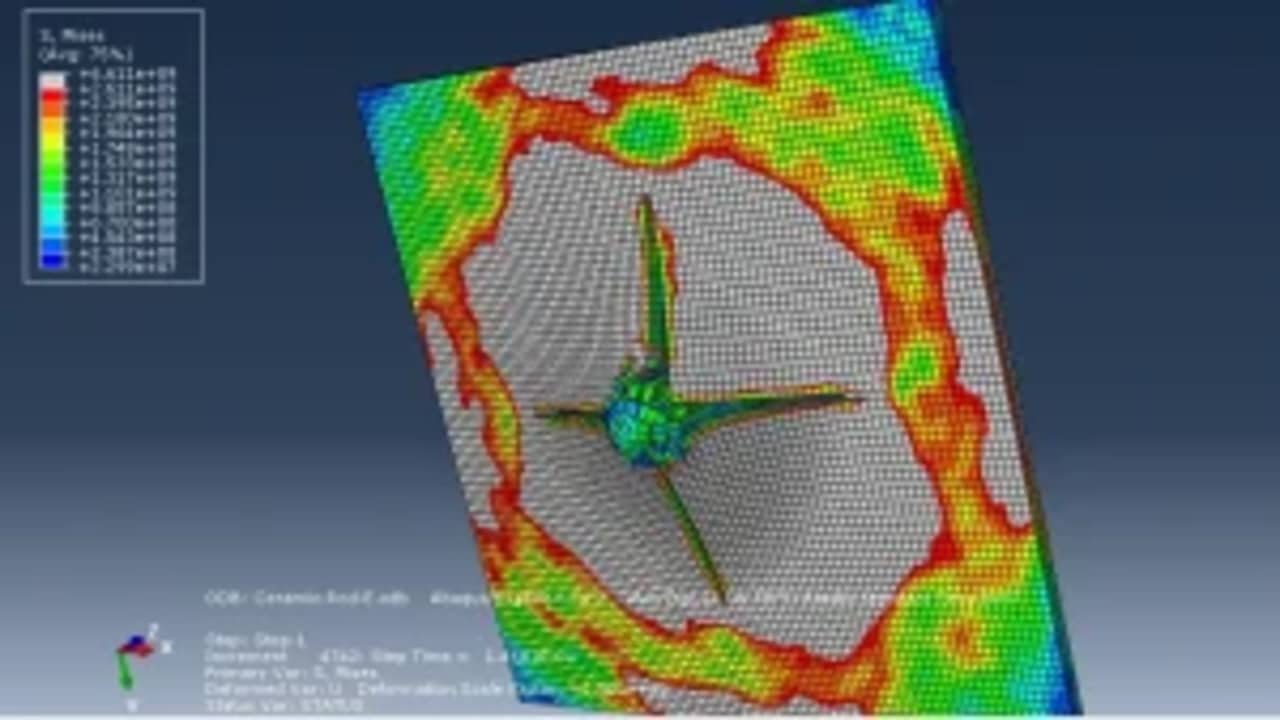

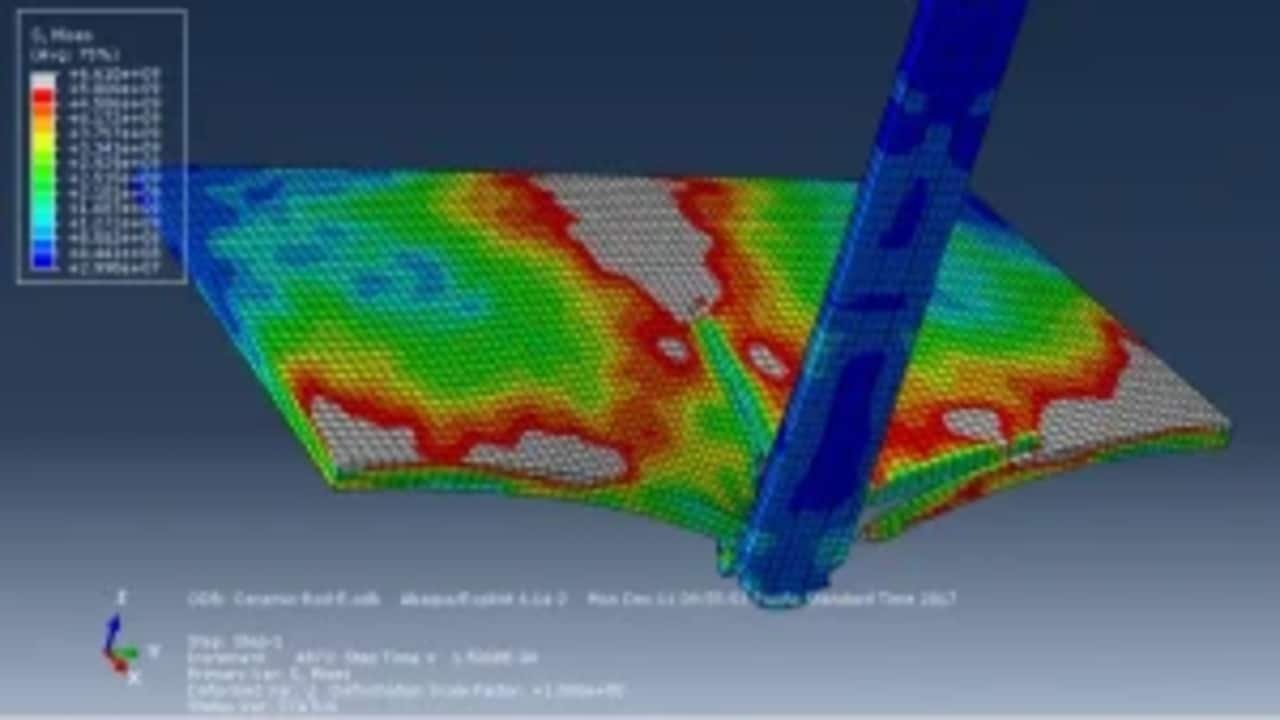

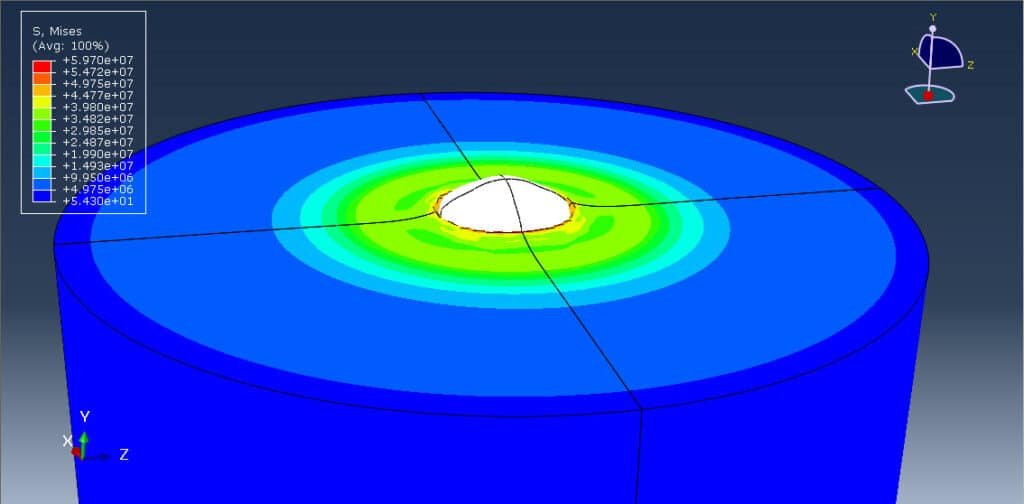

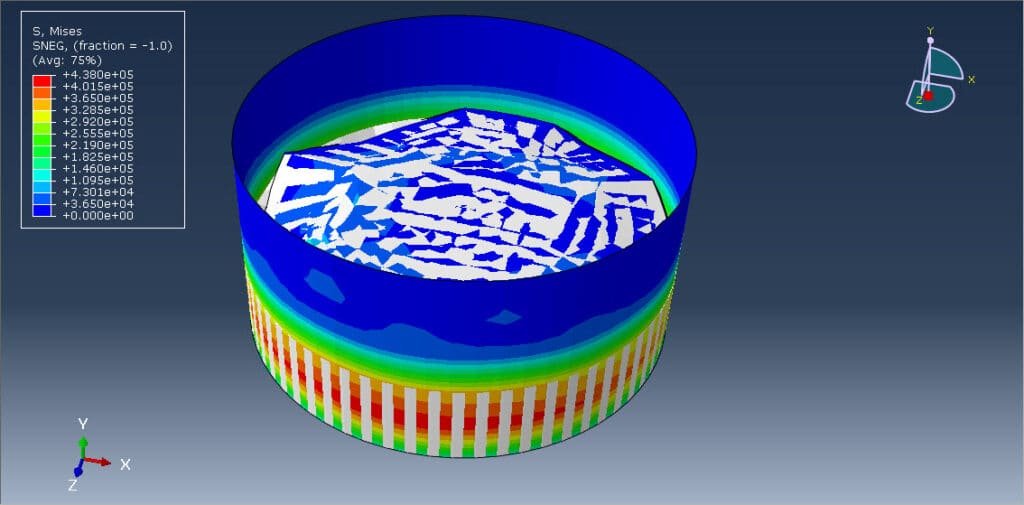

In order to simulate foreign object damage (FOD) phenomenon in aircraft high-pressure compressor blades made of a nickel-based super-alloy, Johnson–Cook (J–C) plasticity model was used. For prediction of material’s plastic behavior at temperature of 400 °C (working temperature of the blades) in the range of strain rates associated with the FOD phenomenon (in order of 106 s21), material parameters of A, B, C, n and m for the J–C plasticity model had to be determined experimentally. Parameters of A, B and n with values of 1108, 699 MPa and 0.5189, respectively, were obtained from quasi-static tensile tests. Moreover, m was determined to be 1.2861, also through quasi-static tensile tests with a strain rate of 1 s21 at three temperatures of 475, 550 and 625 °C. However, in order to determine C, firstly a steel ball was impacted on the surface of a flat specimen made of a precipitation-hardening alloy, and then, the impact site was 3D scanned to obtain the induced crater profile. Finally, the impact test (ballistic) was simulated using Abaqus, and a C value of 0.0085 was determined by comparing the actual crater profile with the one obtained from the simulation through a trial-and-error approach.

Product Overview:

This tutorial provides a step-by-step Abaqus simulation of cold spray deposition, where steel particles impact an Inconel718 target, replicating high-velocity impact conditions. Key simulation steps include:

In this tutorial, particle-substrate interactions are simulated, according to data from the work of Farahani et al.

Acoustic

€100,00 Original price was: €100,00.€99,99Current price is: €99,99.

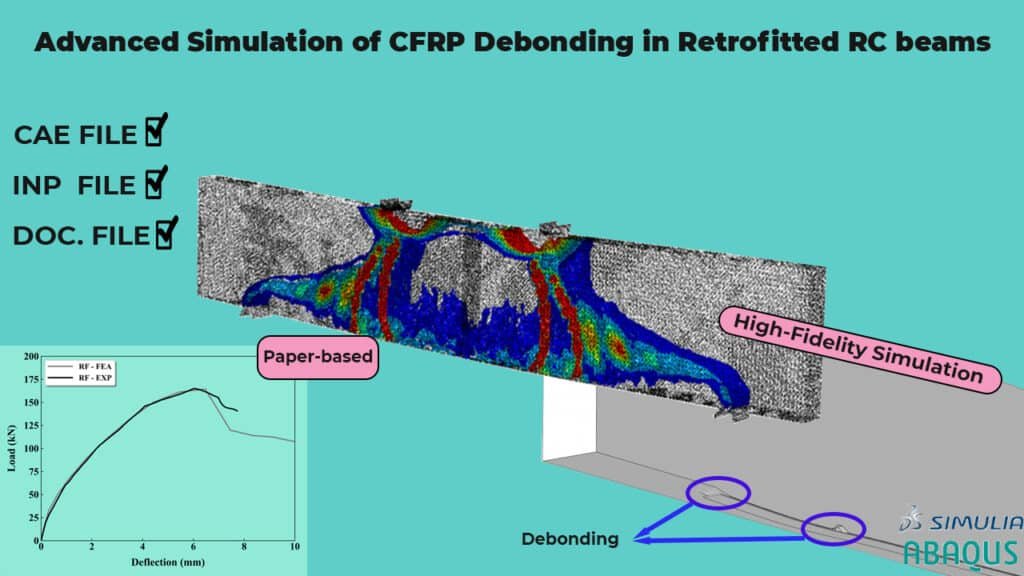

Abaqus

€150,00 Original price was: €150,00.€120,00Current price is: €120,00.

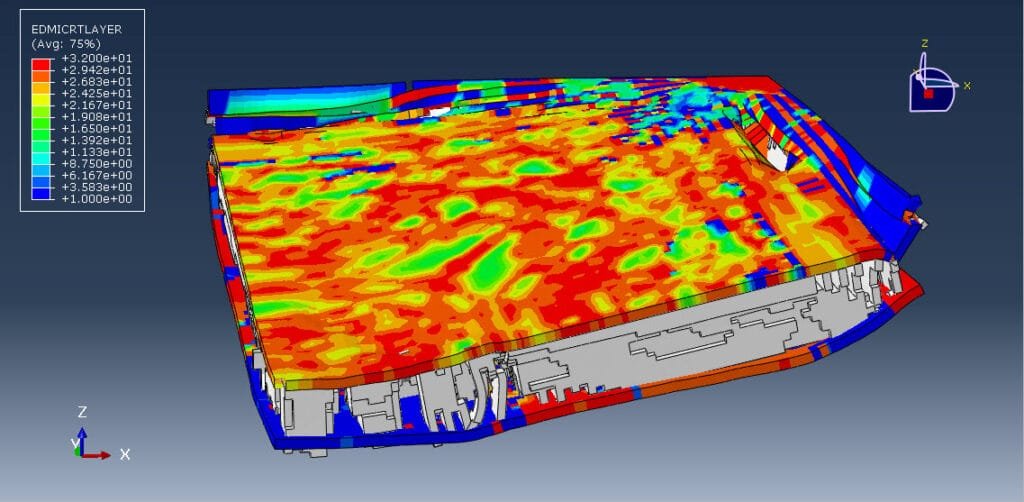

Abaqus

€49,00 Original price was: €49,00.€29,00Current price is: €29,00.

Abaqus

€46,00 Original price was: €46,00.€26,00Current price is: €26,00.

Abaqus

€50,00 Original price was: €50,00.€30,00Current price is: €30,00.

Abaqus

€46,00 Original price was: €46,00.€27,00Current price is: €27,00.

Abaqus

€45,00 Original price was: €45,00.€28,00Current price is: €28,00.

See more

Let’s Learn and Collaborate

Get VIP access to new content.

Sign up for weekly deals and news.

Engineering Downloads is a hub for learning,

collaboration, and sharing engineering models

and resources.

© 2025 Engineering Downloads. All rights reserved.

Want to receive push notifications for all major on-site activities?