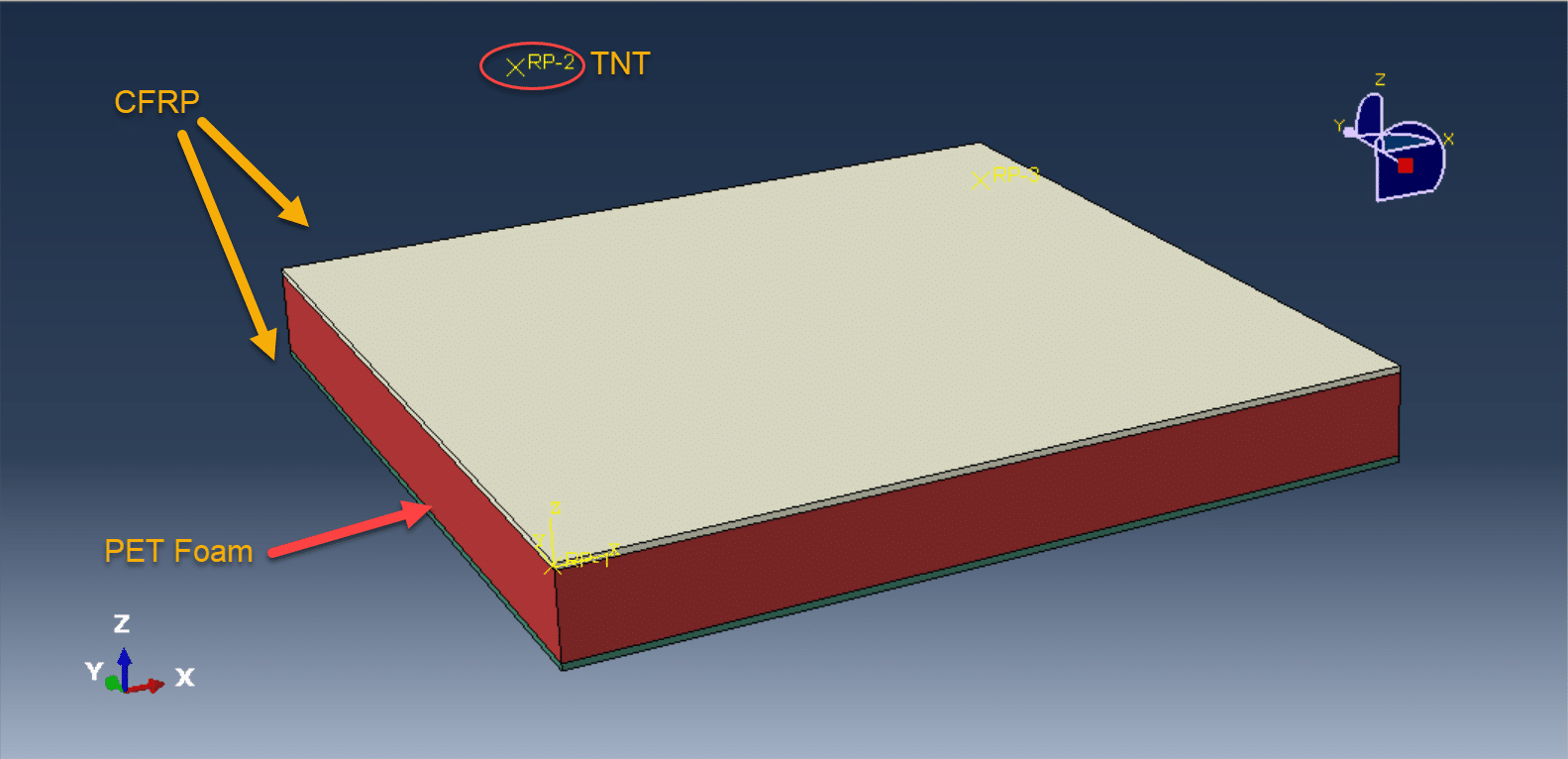

Composite sandwich structures, typically comprising Carbon Fiber Reinforced Polymer (CFRP) face sheets and a lightweight core such as Polyethylene Terephthalate (PET) foam, are widely used in aerospace, automotive, and defense industries due to their high stiffness-to-weight ratio, excellent energy absorption, and tailorable mechanical properties. These panels are increasingly subjected to extreme dynamic loading environments, such as blast waves resulting from explosions or air blasts.

Understanding the response of such structures under air blast loading is critical for:

Safety and survivability design

Lightweight armor systems

Blast-resistant vehicles

Building façade protection

A typical CFRP-PET foam sandwich panel consists of:

CFRP Face Sheets: Provide the majority of the panel’s in-plane stiffness and strength, resist tensile and compressive loads, and protect the core.

PET Foam Core: Provides shear stiffness, thermal insulation, and energy absorption under impact or blast loads. The foam’s compressibility plays a significant role in dissipating blast energy.

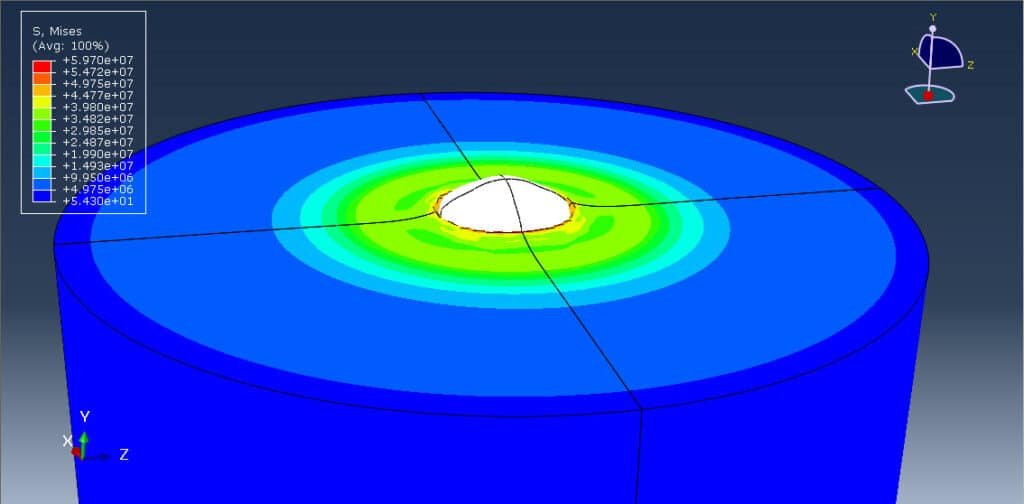

Air blast loading results from rapid energy release in an explosive event, creating a high-pressure shock wave. The blast wave interaction with the panel is characterized by:

Positive overpressure peak

Rapid pressure rise time

Decay of pressure over time

Impulse loading effect

For air blast simulations, the Friedlander equation or blast wave models based on CONWEP data are commonly used to define the pressure-time profile acting on the panel surface.

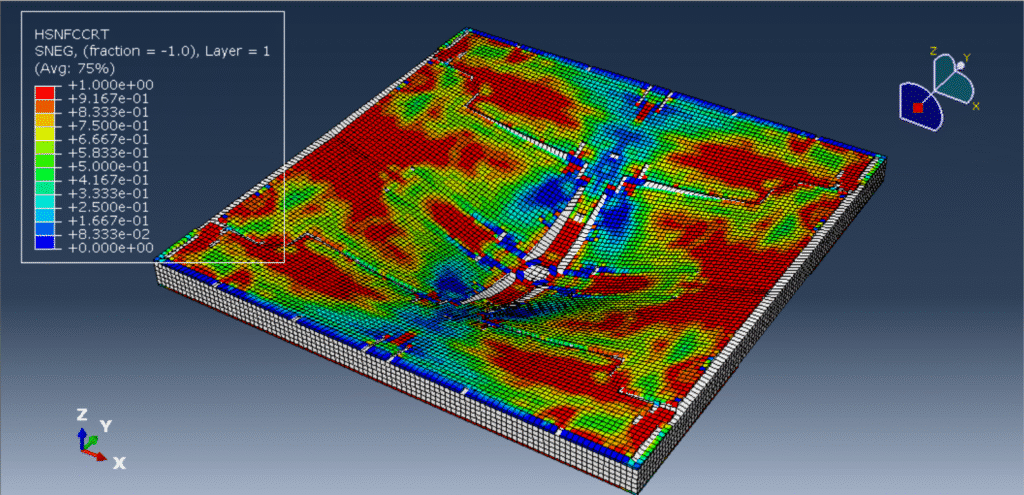

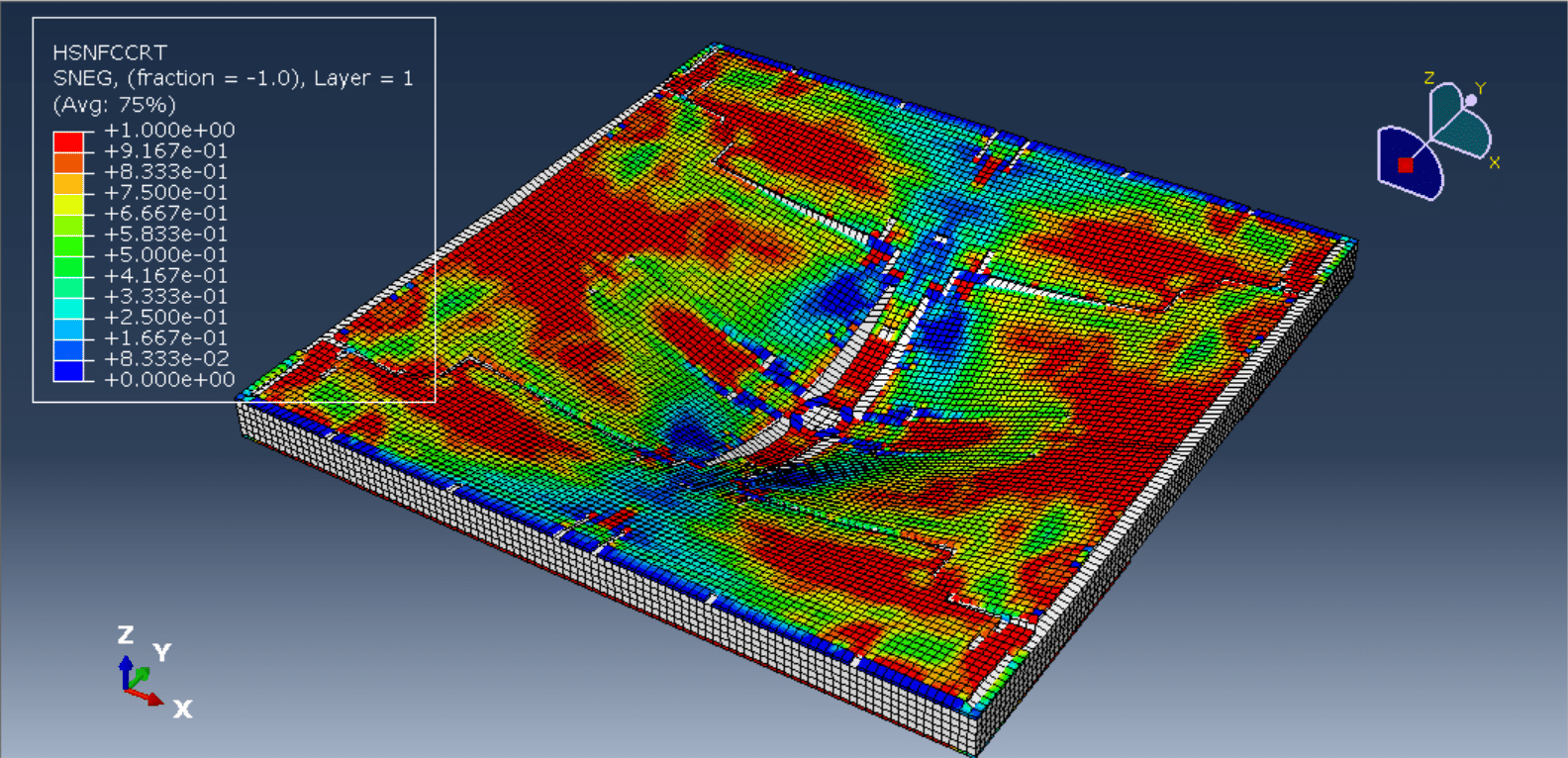

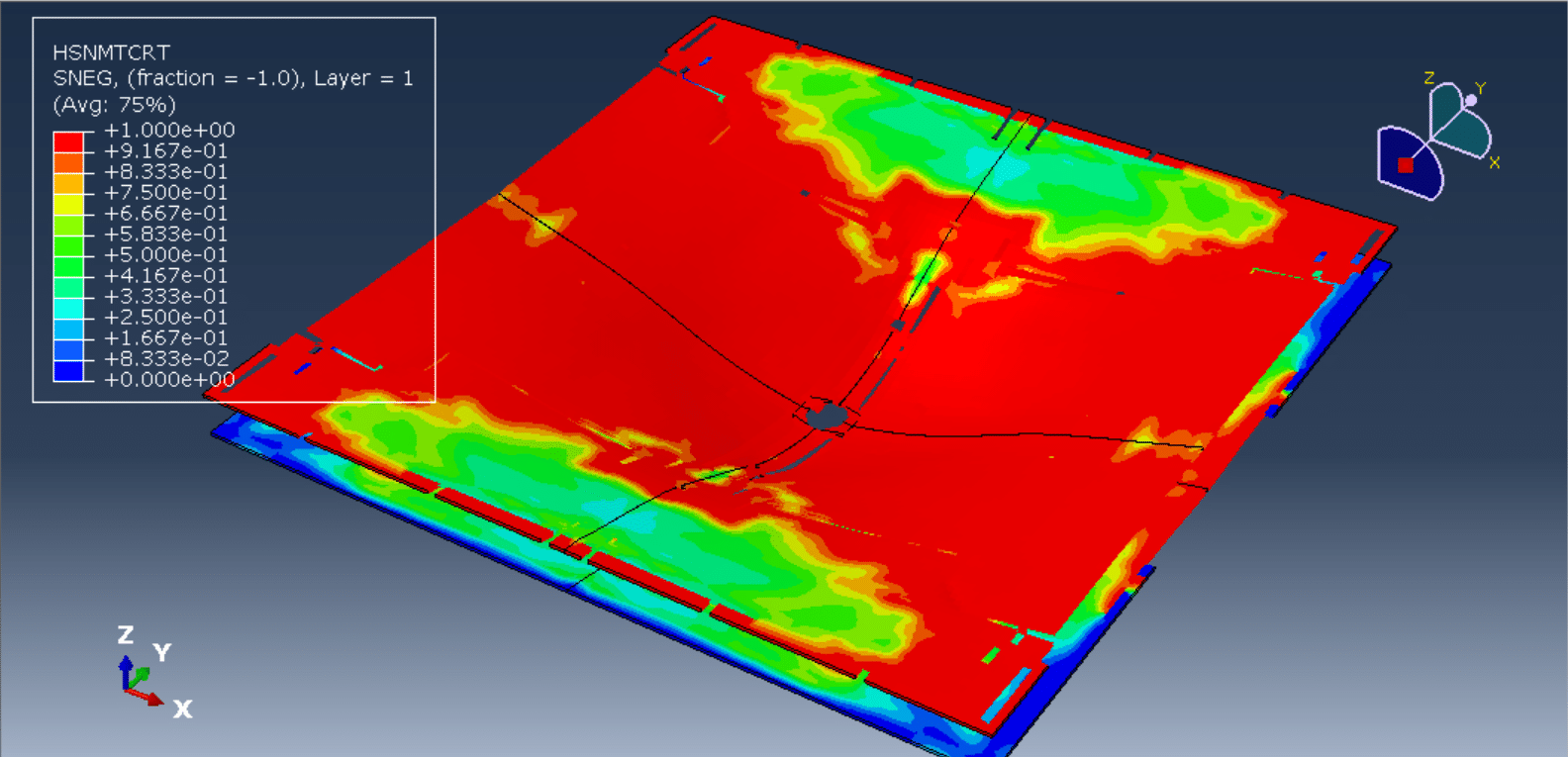

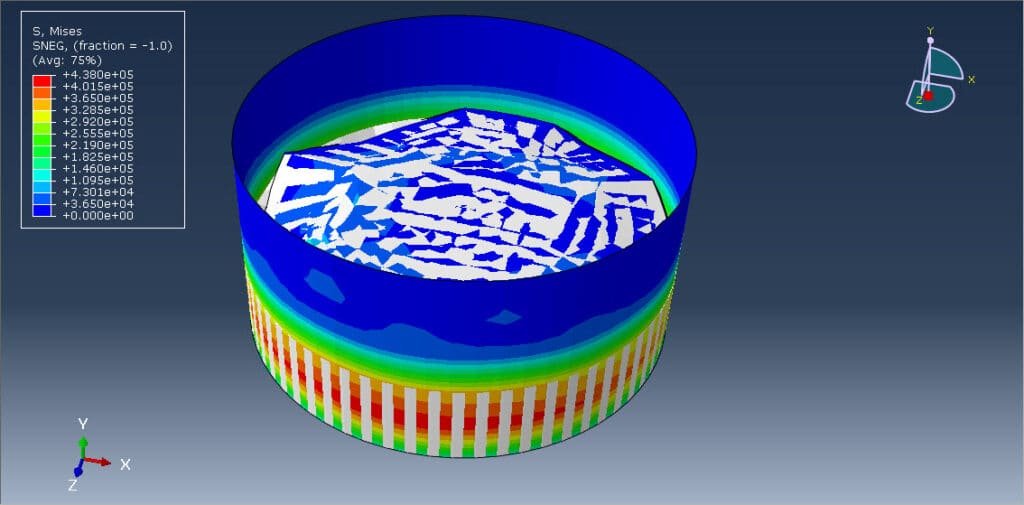

Air blast analysis of composite sandwich panels generally involves numerical simulation, such as finite element modeling (FEM), due to the complexity of interactions:

Material models:

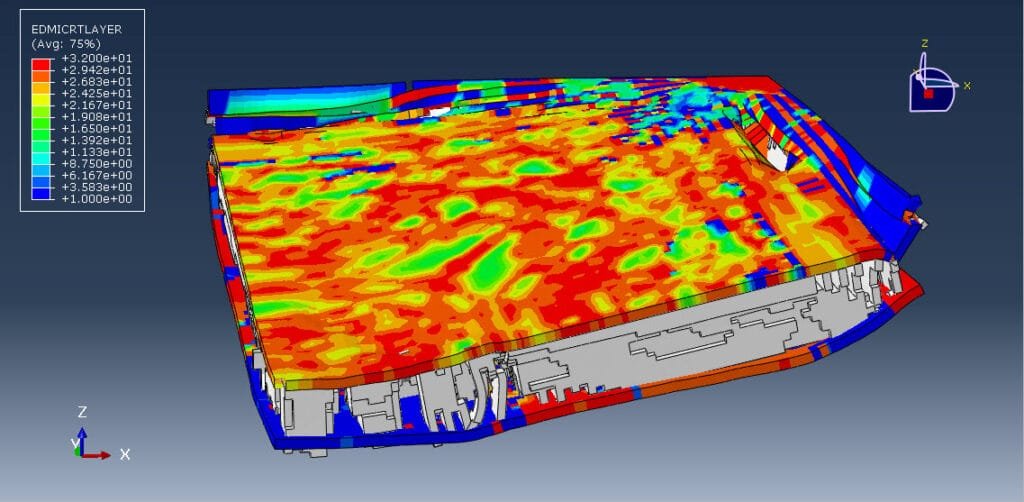

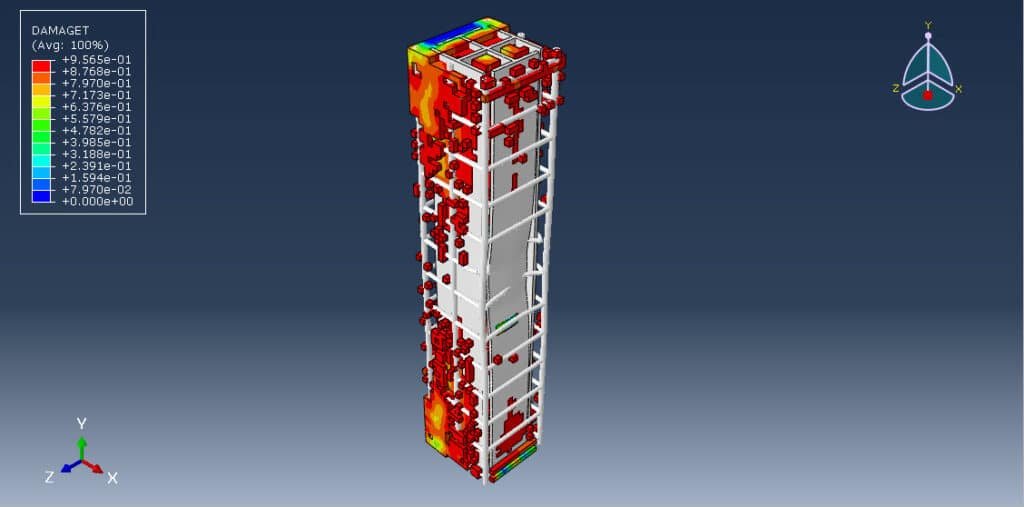

CFRP: Orthotropic elastic-plastic damage models or progressive failure models

PET Foam: Crushable foam models with strain rate sensitivity

Structural response modes:

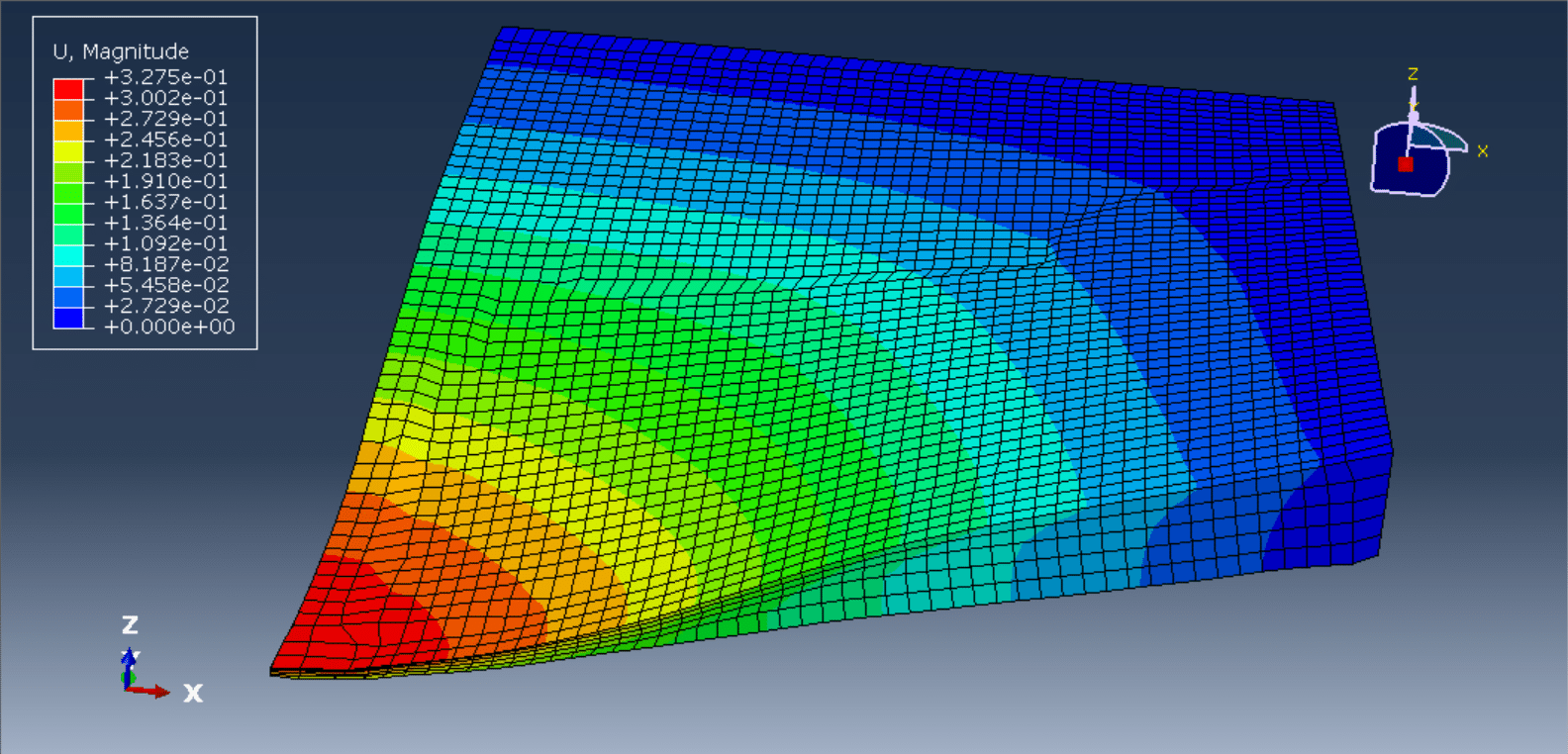

Global bending and deflection

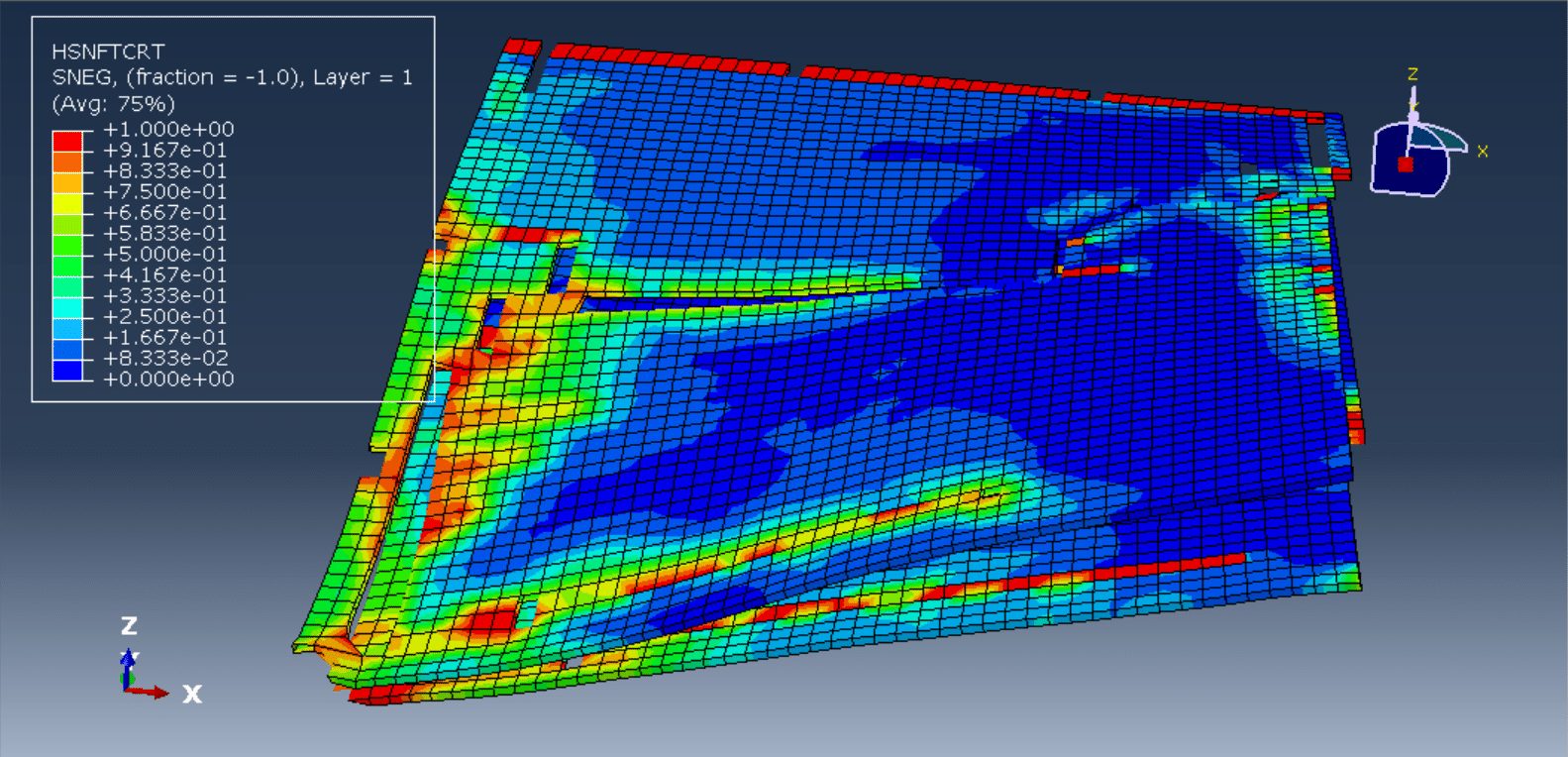

Local face sheet delamination or cracking

Core shear and compression failure

Debonding between faces and core

Research into the air blast response of CFRP-PET panels informs:

Optimized structural design for blast mitigation

Hybrid material configurations (e.g., combining PET with other foams or honeycombs)

Design guidelines for protective structures in defense and civil infrastructure

Acoustic

€100,00 Original price was: €100,00.€99,99Current price is: €99,99.

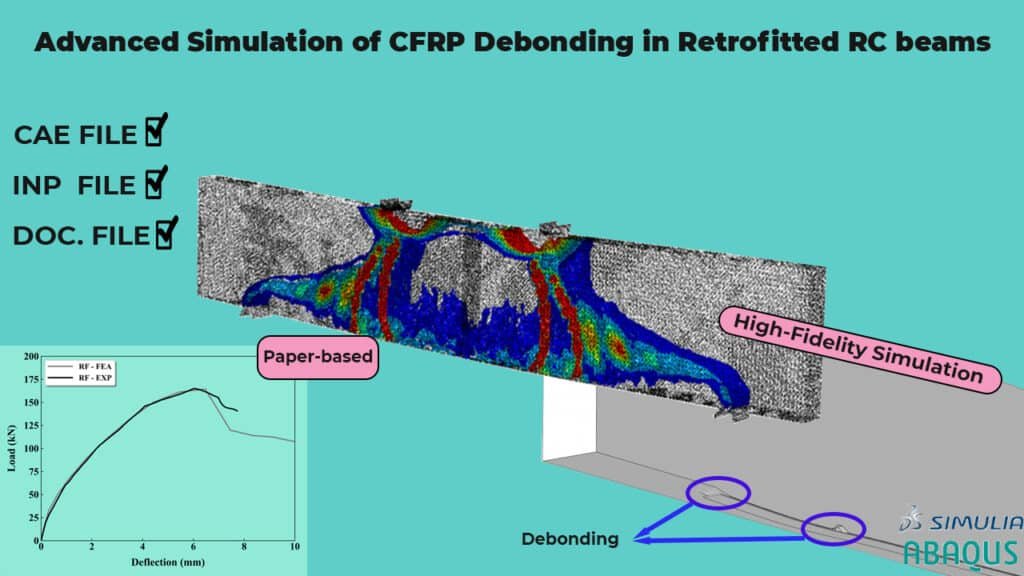

Abaqus

€150,00 Original price was: €150,00.€120,00Current price is: €120,00.

Abaqus

€49,00 Original price was: €49,00.€29,00Current price is: €29,00.

Abaqus

€46,00 Original price was: €46,00.€26,00Current price is: €26,00.

Abaqus

€50,00 Original price was: €50,00.€30,00Current price is: €30,00.

Abaqus

€46,00 Original price was: €46,00.€27,00Current price is: €27,00.

Abaqus

€45,00 Original price was: €45,00.€28,00Current price is: €28,00.

See more

Let’s Learn and Collaborate

Get VIP access to new content.

Sign up for weekly deals and news.

Engineering Downloads is a hub for learning,

collaboration, and sharing engineering models

and resources.

© 2025 Engineering Downloads. All rights reserved.

Want to receive push notifications for all major on-site activities?